PyroGenesis Canada Inc. (http://pyrogenesis.com) (TSX: PYR)

(NASDAQ: PYR) (FRA: 8PY), a high-tech company (hereinafter referred

to as the “Company” or “PyroGenesis”), that designs, develops,

manufactures and commercializes advanced plasma processes and

sustainable solutions which are geared to reduce greenhouse gases

(GHG), is pleased to provide an update further to its press release

dated September 27th, which announced that the Company had signed a

joint venture and license agreement (both agreements collectively

the “JV”) with a leading residue processor (the “JV Partner”) to

ultimately build and operate plants around the globe to transform

dross residues (a by-product of the Company’s DROSRITE™ process)

into high value chemical and metallurgical products. The Company is

proud to announce today that the JV Partner has completed primary

testing of residues from an operational DROSRITE™ facility. The

results confirm that the residues are of such high quality as to be

able to be processed into highly marketable products.

“We are extremely happy to announce today that

for the very first time the existing process, around which we are

basing the joint venture on, has successfully tested residues from

PyroGenesis’ DROSRITE™ metal recovery system,” said P. Peter

Pascali, CEO of PyroGenesis Canada Inc. “Of note, these residues

are from the same site where we plan to build and operate our first

dross residue processing plant. It is expected that this will be

the first plant of several that will be built to transform dross

residues into high value chemicals. Timing could not be more

perfect, as these residues are being increasingly regulated, with

some jurisdictions banning them outright from landfills. The

success of these test results further validates the

“inside-the-fence”, on-site discovery and upsell strategy we have

often described as key to our customer relationships. This bodes

well for our long-term goal of building out and operating many such

plants. These results further demonstrate the value of this JV, and

reinforces PyroGenesis’ strategy as an eventual one-stop shop for

aluminum producers aiming to reduce CO2 emissions with

environmentally friendly processes.”

As background, aluminum dross is a waste

by-product of aluminum production or transformation, created when

the top layer of the molten metal is exposed to oxygen. Composed of

a mix of aluminum metal (typically 60%) as well as oxides and other

chemicals (typically 40%) that get trapped together in this layer,

it is constantly skimmed off and removed from furnaces containing

molten metal. Toxic in nature, dross is stored, landfilled, or

processed, with the goal to recover some of the metal that it

contains.

PyroGenesis’ DROSRITE™ dross processing metal

recovery system can recover up to an industry-leading 98% of the

aluminum metal fraction in dross, returning it directly back to

production. This results in cost savings for aluminum producers,

who benefit with instantly higher output levels, less waste, and

less cost to store or landfill the material.

The material left after DROSRITE™ processing –

the remaining fraction comprising typically 40% of the original

dross – is referred to as secondary dross, dross residue or often

just “residue”. With little purpose in this form, this residue is

most often either disposed in landfills or, in some cases, sold

as-is as a cheap production additive to other industries. It is the

transformation of these residues into high-value products to sell

on the open market – a process known as “valorization” - for which

the 50:50 JV agreement was signed, with an end goal of building and

operating dross residue valorization facilities worldwide to serve

areas of high dross production, and locations where PyroGenesis’

DROSRITE™ systems are operating.

This testing of residue from actual

factory-processed dross was done not only with a view to validate

that the process can manage dross, but more importantly to help

identify the higher value chemicals that result from this specific

dross stream (as chemical composition of dross can vary from

producer to producer).

The Company is happy to report that the results

reveal that the residues are of an extremely high quality, for both

alumina and aluminum nitrides. This reflects both the quality of

the aluminum produced by the Company’s client (a major producer of

aluminum), and of PyroGenesis’ DROSRITE™ process which, unlike

legacy processing technology used by some in the industry, contains

no salt or other contaminants as part of the process.

With these results in hand, steps to confirm

specific techno-economic aspects of the first JV plant can be

completed, a phase that’s ongoing this quarter (Q3) and which is

expected to conclude during the next quarter (Q4), at which point

actual factory planning can commence.

“These preliminary results, while not

surprising, underscore the benefit of utilizing PyroGenesis’

DROSRITE™ system for aluminum dross processing, as well as the

Company’s commitment to finding unique, in-line technology

solutions for heavy industry, particularly the aluminum, steel, and

mining industries,” said Mr. P. Peter Pascali, CEO and Chair of

PyroGenesis. “As we have stated previously, we believe that this

announcement is a game-changer for the aluminum industry, as it

allows PyroGenesis to offer a truly complete dross processing

service, delivering zero-landfill/reduced carbon solutions while at

the same time increasing clients’ profitability. We look forward to

final results and to moving forward with our facility construction

plans, for the first and subsequent factories. As previously

announced, it is expected that the residues can be converted into

high margin products, such as aluminum sulfate and ammonium

sulfate, then sold for use in in-demand applications such as

fertilizer production and water purification for global markets,

thereby rescuing a waste stream and unlocking a potentially

significant new revenue stream for the Company.”

About PyroGenesis Canada

Inc.

PyroGenesis Canada Inc., a high-tech company, is

a leader in the design, development, manufacture and

commercialization of advanced plasma processes and sustainable

solutions which reduce greenhouse gases (GHG), and are economically

attractive alternatives to conventional “dirty” processes.

PyroGenesis has created proprietary, patented and advanced plasm a

technologies that are being vetted and adopted by multiple

multibillion dollar industry leaders in four massive markets: iron

ore pelletization, aluminum, waste management, and additive

manufacturing. With a team of experienced engineers, scientists and

technicians working out of its Montreal office, and its 3,800 m2

and 2,940 m2 manufacturing facilities, PyroGenesis maintains its

competitive advantage by remaining at the forefront of technology

development and commercialization. The operations are ISO

9001:2015 and AS9100D certified, having been ISO certified since

1997. For more information, please visit: www.pyrogenesis.com.

This press release contains certain

forward-looking statements, including, without limitation,

statements containing the words "may", "plan", "will", "estimate",

"continue", "anticipate", "intend", "expect", "in the process" and

other similar expressions which constitute "forward- looking

information" within the meaning of applicable securities laws.

Forward-looking statements reflect the Corporation's current

expectation and assumptions and are subject to a number of risks

and uncertainties that could cause actual results to differ

materially from those anticipated. These forward-looking statements

involve risks and uncertainties including, but not limited to, our

expectations regarding the acceptance of our products by the

market, our strategy to develop new products and enhance the

capabilities of existing products, our strategy with respect to

research and development, the impact of competitive products and

pricing, new product development, and uncertainties related to the

regulatory approval process. Such statements reflect the current

views of the Corporation with respect to future events and are

subject to certain risks and uncertainties and other risks detailed

from time-to-time in the Corporation's ongoing filings with the

securities regulatory authorities, which filings can be found at

www.sedar.com, or at www.sec.gov. Actual results, events, and

performance may differ materially. Readers are cautioned not to

place undue reliance on these forward-looking statements. The

Corporation undertakes no obligation to publicly update or revise

any forward- looking statements either as a result of new

information, future events or otherwise, except as required by

applicable securities laws. Neither the Toronto Stock Exchange, its

Regulation Services Provider (as that term is defined in the

policies of the Toronto Stock Exchange) nor the NASDAQ Stock

Market, LLC accepts responsibility for the adequacy or accuracy of

this press release.

SOURCE PyroGenesis Canada Inc.

For further information please contact: Rodayna

Kafal, Vice President, IR/Comms. and Strategic BDPhone: (514)

937-0002, E-mail: ir@pyrogenesis.com RELATED LINK:

http://www.pyrogenesis.com/

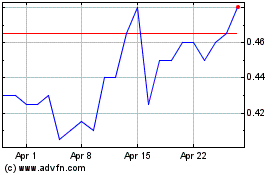

PyroGenesis Canada (TSX:PYR)

Historical Stock Chart

From Mar 2024 to Apr 2024

PyroGenesis Canada (TSX:PYR)

Historical Stock Chart

From Apr 2023 to Apr 2024