Xanadu Mines Ltd (ASX: XAM, TSX: XAM) (Xanadu, XAM or the

Company) is pleased to provide an update on exploration

drilling at the Kharmagtai Project in Mongolia, being developed

with the Company’s joint venture partner

Zijin Mining Group

Co., Ltd. (Zijin). Exploration drilling continues to

expand upon the new zone of higher-grade copper and gold

mineralisation at the White Hill deposit, demonstrating progressive

growth in higher-grade material at the base of the previously

optimised open pits.

Highlights

-

Latest extensional and exploration drilling results expand upon the

recently identified higher-grade zone (core) at White Hill1,

located below the previous Scoping Study pit designs2 and outside

the 2023 Mineral Resource Estimate (MRE) 3. Best

drilling results include:

-

KHDDH808 - 64.45m @ 0.74% CuEq (0.61% Cu & 0.26/t Au)

from 516,Including 24.45m @ 1.41% CuEq (1.14% Cu

& 0.53g/t Au) from 634mIncluding 13.8m @ 1.99%

CuEq (1.64% Cu & 0.70g/t Au) from 558m

-

KHDDH806 - 50m @ 0.73% CuEq (0.25% Cu & 0.94g/t Au)

from 545mIncluding 22m @ 1.34% CuEq (0.26% Cu

& 2.10g/t Au) from 549

-

Expanding higher-grade core (>1% CuEq) at White

Hill is expected to enhance & enlarge the 2023 MRE and to

increase scale & deepen 2022 Scoping Study2 pit shells,

capturing additional higher-grade over longer period.

-

Step-out drilling at Golden Eagle returns grades more than double

the MRE grade and extends mineralisation. Best results include:

-

KHDDH805 - 153.4m @ 0.68g/t AuEq (0.43g/t Au and 0.13% Cu)

from 41.6mIncluding 67m @ 0.97g/t AuEq (0.67g/t Au

and 0.15% Cu) from 44mIncluding 8m @ 1.7g/t AuEq

(1.34g/t Au and 0.18% Cu) from 54mAnd 14m @

1.22g/t AuEq (0.81g/t Au and 0.21% Cu) from 77m

-

Deep drilling hole KHDDH779 encounters two broad zones of porphyry

and tourmaline breccia style mineralisation between Stockwork Hill

and Zaraa, potentially indicating the edges of a very large-scale

Cu-Au System.

-

Growth-focused discovery exploration drilling at Kharmagtai

continues to discover new, shallow mineralisation with potential to

enhance open pit mining and deep mineralisation with potential for

future underground mining.

-

Further assays from deep exploration drilling are pending; we look

forward to sharing over the coming months.

-

Kharmagtai JV is funding US$35M4 for both PFS completion and

discovery exploration, aiming towards decision to mine in

Q4 CY2024.

______________1 ASX/TSX Announcement 7 June 2023 – New

Higher-Grade Zones Found in Kharmagtai Infill Drilling2 ASX/TSX

Announcement 6 April 2022 – Scoping Study – Kharmagtai Copper-Gold

Project3 ASX/TSX Announcement 8 December 2023 – Kharmagtai Mineral

Resource Grows by 13% CuEq; including >25% increase in

higher-grade core

Xanadu’s Executive Chairman and Managing

Director, Mr Colin Moorhead, said “Latest drilling results

provide more evidence for continued growth and improvement at the

Kharmagtai deposit. Importantly, we are expanding the +1% CuEq zone

at White Hill and expending higher-grade mineralisation closer to

surface. Our current geological interpretation suggests that

mineralisation is faulted upwards, towards surface as we expand the

deposit southwards.

“Bulking up the White Hill higher-grade core

will improve the new open pit designs and yield additional copper

within range of open pit mining.”

______________4 ASX/TSX Announcement 13 March

2023 – Zijin & Xanadu Transaction Completed & Kharmagtai

PFS Underway

Figure 1: Kharmagtai

copper-gold district showing defined mineral deposits and completed

infill drill holes, deep exploration drill holes, and shallow

exploration drill holes since the last announced drilling

results5.

______________5 ASX/TSX Announcement 16 November

2023 – Kharmagtai Drilling Achievements Update

Since the last Drilling Market Release (included

in 2023 MRE Update), a total of 5,307m infill diamond drilling has

been completed at Golden Eagle and Zephyr, and 9,320m extensional

and exploration drilling, with both drill core collars and assay

results for each, provided in Tables 1 and 2 (see

Appendix 1).

Step-out Drilling Expands Higher-Grade

Core at White Hill

Three drill holes were collared at White Hill,

and designed to extend the recently discovered higher-grade core,

beneath the 2022 Scoping Study open pits.

Drill hole KHDDH808 was

designed as a 150 to 200m step back from previous drilling

(Figure 2). KHDDH808 intercepted a moderate grade

halo (+0.3% CuEq) over 350m shallower than

expected, and encountered two zones of

higher-grade (+1% CuEq) mineralisation.

|

Hole ID |

Interval (m) |

Cu (%) |

Au (g/t) |

CuEq (%) |

From (m) |

|

KHDDH808 |

64.45 |

0.61 |

0.26 |

0.74 |

516 |

|

including |

24.45 |

1.14 |

0.53 |

1.41 |

634 |

|

including |

13.8 |

1.64 |

0.70 |

1.99 |

558 |

Figure 2: Cross section 591980mE

through the White Hill deposit.

Drill hole KHDDH806 was

designed to test for higher-grade extensions beneath eastern end of

the White Hill open pit (Figure 3). KHDDH806 extended moderate

grade mineralisation for 150m beneath deepest portion of the

previously planned pit, encountering a narrow zone of higher-grade

mineral at the expected depth.

|

Hole ID |

Interval (m) |

Cu (%) |

Au (g/t) |

CuEq (%) |

From (m) |

|

KHDDH806 |

287.4 |

0.18 |

0.07 |

0.21 |

156 |

|

and |

50 |

0.25 |

0.94 |

0.73 |

545 |

|

including |

22 |

0.26 |

2.10 |

1.34 |

549 |

Figure 3: Cross section 592385mE

through the White Hill and Stockwork Hill deposits

Drill hole KHDDH807 was

designed as a 150m step back from previous drilling (Figure

4) and intercepted low to moderate grade halo (+0.2% CuEq)

over 270m shallower than expected. KHDDH807

returned very broad intercept of 559.7m @ 0.27%

CuEq from 435m, including 222m @ 0.36% CuEq from 761m.

Figure

4: Cross section 591820mE through the White Hill

deposit

Infill Drilling Expands Higher-Grade

Gold at Golden Eagle

Five drill holes were collared at Golden Eagle

and designed to extend the new higher-grade gold zone (+1g/t Au) at

Golden Eagle6.

Drill hole KHDDH805 was

designed to join two lobes of higher grade. KHDDH805 intercepted

broad zone of moderate grade gold with a higher-grade zone at the

expected interval (Figure 5). Importantly, the

grades encountered were more than

double those defined in the new 2023 Mineral Resource.

|

Hole ID |

Interval (m) |

Au (g/t) |

Cu (%) |

AuEq (g/t) |

From (m) |

|

KHDDH805 |

153.4 |

0.43 |

0.13 |

0.68 |

41.6 |

|

including |

67 |

0.67 |

0.15 |

0.97 |

44 |

|

including |

8 |

1.34 |

0.18 |

1.7 |

54 |

|

and |

14 |

0.81 |

0.21 |

1.22 |

77 |

Figure 5: Cross section 595400mE

through the Golden Eagle deposit.

______________6 ASX/TSX Announcement – New Gold

Zone Discovered at the Golden Eagle

Drill hole KHDDH801 was designed to extend the

higher-grade zone and has returned a broad zone of moderate grade

gold with a higher-grade zone at the expected interval

(Figure 6).

|

Hole ID |

Interval (m) |

Au (g/t) |

Cu (%) |

AuEq (g/t) |

From (m) |

|

KHDDH801 |

83.4 |

0.59 |

0.11 |

0.8 |

36.6 |

|

including |

29 |

1.14 |

0.14 |

1.42 |

57 |

|

including |

14 |

1.9 |

0.14 |

2.18 |

60 |

Figure 6: Cross section 595275mE

through the Golden Eagle deposit.

Deep Exploration Drilling Encounters

Broad Mineralised Zone

A single deep diamond drill hole was collared

between Zaraa and Stockwork Hill, designed to test for a

large-scale porphyry deposit. KHDDH779 encountered two broad zones

of porphyry and tourmaline breccia style mineralisation between

Stockwork Hill and Zaraa (Figure 7). This hole

appears to have encountered the edges of a very large-scale Cu-Au

System. Additional work is being planned once full interpretations

are completed and the BoxScan dataset (vein densities, SWIR,

sulphide distribution etc) are incorporated into the broader

exploration model.

Figure 7: Cross section drill

hole KHDDH779

About Xanadu Mines

Xanadu is an ASX and TSX listed Exploration

company operating in Mongolia. We give investors exposure to

globally significant, large-scale copper-gold discoveries and

low-cost inventory growth. Xanadu maintains a portfolio of

exploration projects and remains one of the few junior explorers on

the ASX or TSX who jointly control a globally significant

copper-gold deposit in our flagship Kharmagtai project. Xanadu is

the Operator of a 50-50 JV with Zijin Mining Group in Khuiten

Metals Pte Ltd, which controls 76.5% of the Kharmagtai project.

For further information on Xanadu, please visit:

www.xanadumines.com or contact:

Colin MoorheadExecutive Chairman & Managing

DirectorE: colin.moorhead@xanadumines.com P: +61 2 8280 7497

This Announcement was authorised for release by

Xanadu’s Board of Directors.

Appendix 1: Drilling Results

Note that true widths will generally be narrower

than those reported. See disclosure in JORC explanatory statement

attached.

Table 1: Drill hole collar

|

Hole ID |

Prospect |

East |

North |

RL |

Azimuth (°) |

Inc (°) |

Depth (m) |

|

KHDDH684 |

Golden Eagle |

595224 |

4876746 |

1270 |

359 |

-60 |

341.0 |

|

KHDDH685 |

Golden Eagle |

595226 |

4876847 |

1269 |

360 |

-60 |

325.0 |

|

KHDDH700 |

Golden Eagle |

595598 |

4876901 |

1269 |

0 |

-60 |

267.0 |

|

KHDDH701 |

Golden Eagle |

595597 |

4877002 |

1268 |

0 |

-60 |

220.0 |

|

KHDDH703 |

Zephyr |

594899 |

4877696 |

1265 |

0 |

-60 |

52.7 |

|

KHDDH704 |

Zephyr |

594900 |

4877796 |

1264 |

0 |

-60 |

72.7 |

|

KHDDH705 |

Zephyr |

595023 |

4877598 |

1265 |

0 |

-60 |

100.0 |

|

KHDDH706 |

Zephyr |

595024 |

4877698 |

1265 |

0 |

-60 |

175.0 |

|

KHDDH707 |

Zephyr |

595146 |

4877446 |

1266 |

0 |

-60 |

75.0 |

|

KHDDH709 |

Zephyr |

595147 |

4877646 |

1265 |

0 |

-60 |

100.0 |

|

KHDDH710 |

Zephyr |

595148 |

4877746 |

1264 |

0 |

-60 |

140.0 |

|

KHDDH711 |

Zephyr |

595274 |

4877399 |

1266 |

0 |

-60 |

100.0 |

|

KHDDH712 |

Zephyr |

595023 |

4877697 |

1265 |

240 |

-60 |

150.0 |

|

KHDDH713 |

Zephyr |

595273 |

4877598 |

1265 |

0 |

-60 |

189.4 |

|

KHDDH714 |

Zephyr |

595274 |

4877697 |

1265 |

0 |

-60 |

150.0 |

|

KHDDH715 |

Zephyr |

595023 |

4877800 |

1264 |

0 |

-60 |

125.1 |

|

KHDDH716 |

Zephyr |

595149 |

4877544 |

1266 |

0 |

-60 |

75.0 |

|

KHDDH717 |

Zephyr |

595275 |

4877498 |

1266 |

0 |

-60 |

235.0 |

|

KHDDH718 |

Zephyr |

595397 |

4877445 |

1267 |

0 |

-60 |

125.0 |

|

KHDDH719 |

Zephyr |

595146 |

4877544 |

1266 |

270 |

-55 |

160.0 |

|

KHDDH720 |

Zephyr |

595399 |

4877750 |

1265 |

0 |

-60 |

100.0 |

|

KHDDH721 |

Zephyr |

595523 |

4877497 |

1266 |

0 |

-60 |

400.0 |

|

KHDDH722 |

Zephyr |

595524 |

4877698 |

1265 |

0 |

-60 |

150.0 |

|

KHDDH723 |

Zephyr |

595649 |

4877663 |

1266 |

0 |

-60 |

205.0 |

|

KHDDH724 |

Zephyr |

595275 |

4877497 |

1266 |

190 |

-75 |

190.0 |

|

KHDDH725 |

Zephyr |

595773 |

4877664 |

1269 |

0 |

-60 |

75.0 |

|

KHDDH731 |

Zephyr |

595394 |

4877512 |

1266 |

170 |

-60 |

160.0 |

|

KHDDH732 |

Zephyr |

595397 |

4877651 |

1266 |

0 |

-60 |

200.0 |

|

KHDDH736 |

Zephyr |

595524 |

4877596 |

1265 |

0 |

-60 |

214.0 |

|

KHDDH740 |

Zephyr |

595525 |

4877797 |

1265 |

0 |

-60 |

125.0 |

|

KHDDH745 |

Zephyr |

595774 |

4877744 |

1270 |

0 |

-60 |

100.0 |

|

KHDDH752 |

Zephyr |

595524 |

4877595 |

1265 |

140 |

-75 |

210.0 |

|

KHDDH779 |

Exploration |

593999 |

4876523 |

1285 |

0 |

-70 |

2400.0 |

|

KHDDH801 |

Golden Eagle |

595277 |

4876894 |

1269 |

0 |

-60 |

288.5 |

|

KHDDH802 |

Golden Eagle |

595332 |

4876839 |

1270 |

0 |

-60 |

285.5 |

|

KHDDH803 |

Golden Eagle |

595401 |

4876841 |

1269 |

0 |

-60 |

291.0 |

|

KHDDH804 |

Golden Eagle |

595328 |

4876942 |

1269 |

0 |

-60 |

279.5 |

|

KHDDH805 |

Golden Eagle |

595399 |

4876919 |

1269 |

0 |

-60 |

279.6 |

|

KHDDH806 |

White Hill |

592393 |

4877472 |

1293 |

180 |

-70 |

848.3 |

|

KHDDH807 |

White Hill |

591788 |

4876469 |

1317 |

0 |

-60 |

1212.7 |

|

KHDDH808 |

White Hill |

591959 |

4876661 |

1310 |

0 |

-60 |

1200.0 |

|

KHDDH809 |

Exploration |

597845 |

4877219 |

1265 |

0 |

-70 |

1200.0 |

|

KHDDH810 |

Altan Shand |

591291 |

4878056 |

1296 |

318 |

-60 |

444.6 |

|

KHDDH811 |

White Hill |

591099 |

4877967 |

1296 |

315 |

-60 |

450.8 |

|

KHDDH812 |

White Hill |

591328 |

4878186 |

1291 |

318 |

-60 |

230.0 |

Table 2: Significant drill

results

|

Hole ID |

Prospect |

From (m) |

To (m) |

Interval (m) |

Au (g/t) |

Cu (%) |

CuEq (%) |

AuEq (g/t) |

|

KHDDH684 |

Golden Eagle |

49 |

248 |

199 |

0.15 |

0.09 |

0.17 |

0.34 |

|

including |

|

186 |

220 |

34 |

0.33 |

0.17 |

0.34 |

0.67 |

|

and |

|

282.5 |

341 |

58.5 |

0.09 |

0.16 |

0.20 |

0.39 |

|

KHDDH685 |

Golden Eagle |

34 |

325 |

291 |

0.22 |

0.14 |

0.25 |

0.49 |

|

including |

|

70 |

74 |

4 |

1.26 |

0.14 |

0.78 |

1.53 |

|

including |

|

124 |

133.6 |

9.6 |

0.18 |

0.16 |

0.25 |

0.50 |

|

including |

|

144.95 |

240 |

95.05 |

0.35 |

0.16 |

0.34 |

0.66 |

|

KHDDH700 |

Golden Eagle |

43.5 |

196 |

152.5 |

0.22 |

0.09 |

0.20 |

0.39 |

|

including |

|

96 |

106 |

10 |

0.35 |

0.14 |

0.32 |

0.63 |

|

including |

|

168 |

182 |

14 |

0.59 |

0.15 |

0.46 |

0.89 |

|

including |

|

172 |

176 |

4 |

1.10 |

0.24 |

0.80 |

1.56 |

|

KHDDH701 |

Golden Eagle |

40.25 |

123 |

82.75 |

0.16 |

0.09 |

0.18 |

0.34 |

|

including |

|

42 |

46 |

4 |

0.46 |

0.16 |

0.39 |

0.76 |

|

KHDDH703 |

Zephyr |

14.75 |

18.8 |

4.05 |

0.33 |

0.00 |

0.17 |

0.34 |

|

KHDDH704 |

Zephyr |

No significant intercepts |

|

KHDDH705 |

Zephyr |

14 |

42 |

28 |

0.28 |

0.03 |

0.18 |

0.35 |

|

and |

|

58 |

64 |

6 |

0.40 |

0.05 |

0.25 |

0.50 |

|

and |

|

78 |

86 |

8 |

0.11 |

0.02 |

0.08 |

0.15 |

|

KHDDH706 |

Zephyr |

No significant intercepts |

|

KHDDH707 |

Zephyr |

23.9 |

74 |

50.1 |

0.19 |

0.04 |

0.14 |

0.27 |

|

including |

|

48 |

64 |

16 |

0.47 |

0.04 |

0.28 |

0.55 |

|

KHDDH708 |

Zephyr |

40.3 |

157 |

116.7 |

0.18 |

0.09 |

0.18 |

0.35 |

|

including |

|

52 |

58 |

6 |

0.49 |

0.09 |

0.34 |

0.66 |

|

and |

|

171 |

187.1 |

16.1 |

0.26 |

0.04 |

0.17 |

0.33 |

|

and |

|

223 |

227.2 |

4.2 |

0.50 |

0.03 |

0.29 |

0.56 |

|

KHDDH709 |

Zephyr |

16 |

20 |

4 |

0.22 |

0.00 |

0.12 |

0.23 |

|

and |

|

51 |

58 |

7 |

0.20 |

0.03 |

0.14 |

0.27 |

|

KHDDH710 |

Zephyr |

No significant intercepts |

|

KHDDH711 |

Zephyr |

32 |

100 |

68 |

0.09 |

0.10 |

0.15 |

0.29 |

|

KHDDH712 |

Zephyr |

19 |

28 |

9 |

0.14 |

0.02 |

0.09 |

0.17 |

|

and |

|

41.9 |

57.6 |

15.7 |

0.42 |

0.02 |

0.24 |

0.46 |

|

and |

|

121 |

132 |

11 |

0.05 |

0.05 |

0.07 |

0.14 |

|

KHDDH713 |

Zephyr |

18.5 |

56 |

37.5 |

0.25 |

0.08 |

0.20 |

0.40 |

|

including |

|

40 |

48 |

8 |

0.74 |

0.16 |

0.54 |

1.06 |

|

and |

|

76 |

107.2 |

31.2 |

0.14 |

0.06 |

0.13 |

0.26 |

|

and |

|

129 |

140.7 |

11.7 |

0.14 |

0.06 |

0.13 |

0.26 |

|

and |

|

152 |

189.4 |

37.4 |

0.17 |

0.07 |

0.15 |

0.30 |

|

KHDDH714 |

Zephyr |

30 |

38 |

8 |

0.19 |

0.02 |

0.12 |

0.23 |

|

and |

|

48 |

52 |

4 |

0.31 |

0.03 |

0.18 |

0.35 |

|

and |

|

113 |

121 |

8 |

0.27 |

0.01 |

0.15 |

0.29 |

|

and |

|

135 |

142 |

7 |

0.22 |

0.01 |

0.12 |

0.24 |

|

KHDDH715 |

Zephyr |

No significant intercepts |

|

KHDDH716 |

Zephyr |

15.9 |

75 |

59.1 |

0.09 |

0.10 |

0.14 |

0.28 |

|

KHDDH717 |

Zephyr |

16.2 |

235 |

218.8 |

0.20 |

0.13 |

0.23 |

0.45 |

|

including |

|

47 |

73 |

26 |

0.46 |

0.24 |

0.47 |

0.93 |

|

including |

|

138 |

144 |

6 |

0.27 |

0.17 |

0.31 |

0.60 |

|

including |

|

205 |

223 |

18 |

0.21 |

0.22 |

0.33 |

0.64 |

|

KHDDH718 |

Zephyr |

49 |

67 |

18 |

0.25 |

0.04 |

0.16 |

0.32 |

|

and |

|

149 |

153 |

4 |

0.19 |

0.05 |

0.14 |

0.28 |

|

and |

|

171 |

356 |

185 |

0.21 |

0.12 |

0.22 |

0.44 |

|

including |

|

211 |

215 |

4 |

0.42 |

0.17 |

0.38 |

0.75 |

|

including |

|

265 |

276 |

11 |

0.86 |

0.16 |

0.60 |

1.17 |

|

including |

|

269.5 |

276 |

6.5 |

1.29 |

0.15 |

0.81 |

1.59 |

|

including |

|

304 |

338 |

34 |

0.33 |

0.20 |

0.37 |

0.72 |

|

KHDDH719 |

Zephyr |

45 |

49 |

4 |

0.19 |

0.04 |

0.14 |

0.27 |

|

and |

|

91 |

160 |

69 |

0.13 |

0.07 |

0.13 |

0.26 |

|

KHDDH720 |

Zephyr |

38 |

62 |

24 |

0.16 |

0.09 |

0.17 |

0.33 |

|

KHDDH721 |

Zephyr |

104 |

120 |

16 |

0.16 |

0.05 |

0.13 |

0.25 |

|

and |

|

139.5 |

336.9 |

197.4 |

0.13 |

0.16 |

0.23 |

0.45 |

|

including |

|

166 |

172 |

6 |

0.10 |

0.30 |

0.35 |

0.68 |

|

including |

|

193 |

221 |

28 |

0.15 |

0.26 |

0.34 |

0.66 |

|

including |

|

273 |

311 |

38 |

0.19 |

0.21 |

0.31 |

0.60 |

|

including |

|

327 |

336 |

9 |

0.24 |

0.17 |

0.29 |

0.57 |

|

and |

|

347 |

395 |

48 |

0.11 |

0.14 |

0.19 |

0.38 |

|

including |

|

369 |

389 |

20 |

0.11 |

0.21 |

0.27 |

0.52 |

|

KHDDH722 |

Zephyr |

23.2 |

144 |

120.8 |

0.26 |

0.18 |

0.32 |

0.62 |

|

including |

|

23.2 |

87 |

63.8 |

0.44 |

0.25 |

0.47 |

0.93 |

|

including |

|

25 |

45 |

20 |

0.89 |

0.25 |

0.70 |

1.37 |

|

including |

|

65 |

76.8 |

11.8 |

0.36 |

0.42 |

0.60 |

1.18 |

|

KHDDH723 |

Zephyr |

43 |

246 |

203 |

0.18 |

0.16 |

0.25 |

0.50 |

|

including |

|

83 |

103 |

20 |

0.13 |

0.33 |

0.39 |

0.77 |

|

including |

|

121 |

129 |

8 |

0.14 |

0.22 |

0.29 |

0.57 |

|

including |

|

141 |

149 |

8 |

0.31 |

0.30 |

0.45 |

0.89 |

|

including |

|

163 |

189 |

26 |

0.23 |

0.18 |

0.30 |

0.59 |

|

including |

|

199 |

219 |

20 |

0.55 |

0.16 |

0.44 |

0.85 |

|

including |

|

201 |

211 |

10 |

0.89 |

0.16 |

0.62 |

1.21 |

|

including |

|

232.7 |

242.3 |

9.6 |

0.23 |

0.09 |

0.20 |

0.40 |

|

and |

|

268 |

272 |

4 |

0.10 |

0.07 |

0.12 |

0.24 |

|

and |

|

312 |

316 |

4 |

0.16 |

0.05 |

0.13 |

0.25 |

|

KHDDH724 |

Zephyr |

13.6 |

118.5 |

104.9 |

0.21 |

0.16 |

0.27 |

0.52 |

|

including |

|

13.6 |

66 |

52.4 |

0.35 |

0.19 |

0.36 |

0.71 |

|

including |

|

26 |

38 |

12 |

0.31 |

0.34 |

0.50 |

0.97 |

|

and |

|

165 |

188 |

23 |

0.22 |

0.05 |

0.16 |

0.32 |

|

KHDDH725 |

Zephyr |

No significant intercepts |

|

KHDDH731 |

Zephyr |

59 |

65 |

6 |

0.22 |

0.03 |

0.14 |

0.28 |

|

and |

|

89 |

101 |

12 |

0.22 |

0.03 |

0.14 |

0.27 |

|

KHDDH732 |

Zephyr |

21.6 |

62 |

40.4 |

0.10 |

0.12 |

0.17 |

0.34 |

|

and |

|

74 |

200 |

126 |

0.13 |

0.22 |

0.29 |

0.57 |

|

including |

|

74 |

88 |

14 |

0.23 |

0.20 |

0.32 |

0.63 |

|

including |

|

98 |

108.2 |

10.2 |

0.23 |

0.25 |

0.37 |

0.72 |

|

including |

|

119.4 |

171 |

51.6 |

0.12 |

0.29 |

0.35 |

0.69 |

|

KHDDH736 |

Zephyr |

48 |

54 |

6 |

0.07 |

0.08 |

0.12 |

0.23 |

|

and |

|

68 |

264 |

196 |

0.25 |

0.12 |

0.25 |

0.48 |

|

including |

|

128 |

163.8 |

35.8 |

0.33 |

0.17 |

0.34 |

0.67 |

|

including |

|

184.2 |

211 |

26.8 |

1.00 |

0.16 |

0.68 |

1.32 |

|

including |

|

184.2 |

188.9 |

4.7 |

1.23 |

0.37 |

1.00 |

1.96 |

|

including |

|

200 |

209 |

9 |

1.77 |

0.17 |

1.07 |

2.10 |

|

KHDDH740 |

Zephyr |

31.2 |

59 |

27.8 |

0.04 |

0.10 |

0.12 |

0.23 |

|

KHDDH745 |

Zephyr |

38.8 |

104.9 |

66.1 |

0.10 |

0.21 |

0.26 |

0.51 |

|

including |

|

60 |

80 |

20 |

0.13 |

0.27 |

0.33 |

0.65 |

|

and |

|

171 |

179.2 |

8.2 |

0.16 |

0.06 |

0.15 |

0.29 |

|

and |

|

242 |

256 |

14 |

0.25 |

0.03 |

0.16 |

0.31 |

|

including |

|

242 |

252 |

10 |

0.32 |

0.03 |

0.20 |

0.38 |

|

and |

|

270 |

351 |

81 |

0.14 |

0.09 |

0.17 |

0.33 |

|

including |

|

270 |

277.3 |

7.3 |

0.53 |

0.07 |

0.34 |

0.66 |

|

including |

|

293 |

299 |

6 |

0.22 |

0.21 |

0.32 |

0.62 |

|

KHDDH752 |

Zephyr |

27.5 |

40 |

12.5 |

0.08 |

0.03 |

0.07 |

0.15 |

|

and |

|

111.1 |

118 |

6.9 |

0.07 |

0.07 |

0.10 |

0.20 |

|

and |

|

142 |

210 |

68 |

0.08 |

0.19 |

0.23 |

0.45 |

|

including |

|

156 |

160 |

4 |

0.29 |

0.24 |

0.39 |

0.76 |

|

including |

|

202 |

208 |

6 |

0.08 |

0.28 |

0.32 |

0.62 |

|

KHDDH779 |

Exploration |

66 |

78 |

12 |

0.13 |

0.08 |

0.14 |

0.28 |

|

and |

|

320 |

326 |

6 |

0.35 |

0.13 |

0.31 |

0.60 |

|

and |

|

499 |

505 |

6 |

0.01 |

0.11 |

0.11 |

0.22 |

|

and |

|

557 |

577 |

20 |

0.09 |

0.12 |

0.16 |

0.32 |

|

and |

|

587 |

595 |

8 |

0.02 |

0.11 |

0.12 |

0.23 |

|

and |

|

611 |

621 |

10 |

0.02 |

0.08 |

0.09 |

0.18 |

|

and |

|

661 |

673 |

12 |

0.04 |

0.08 |

0.11 |

0.21 |

|

and |

|

782 |

788 |

6 |

0.06 |

0.07 |

0.10 |

0.19 |

|

and |

|

810 |

820 |

10 |

0.05 |

0.07 |

0.10 |

0.19 |

|

and |

|

874 |

1118 |

244 |

0.03 |

0.13 |

0.15 |

0.29 |

|

including |

|

980 |

984 |

4 |

0.09 |

0.28 |

0.33 |

0.64 |

|

including |

|

1087 |

1098 |

11 |

0.05 |

0.19 |

0.22 |

0.42 |

|

and |

|

1132 |

1430 |

298 |

0.07 |

0.13 |

0.17 |

0.33 |

|

including |

|

1253.65 |

1263 |

9.35 |

0.06 |

0.23 |

0.26 |

0.51 |

|

including |

|

1362 |

1367 |

5 |

1.11 |

0.32 |

0.89 |

1.73 |

|

and |

|

1442 |

1486 |

44 |

0.06 |

0.08 |

0.11 |

0.22 |

|

and |

|

1496 |

1517 |

21 |

0.01 |

0.09 |

0.10 |

0.19 |

|

and |

|

1577 |

1585 |

8 |

0.16 |

0.15 |

0.23 |

0.44 |

|

and |

|

1649 |

1658 |

9 |

0.02 |

0.04 |

0.05 |

0.10 |

|

and |

|

1724 |

1730 |

6 |

0.03 |

0.15 |

0.17 |

0.33 |

|

and |

|

1756 |

1831 |

75 |

0.07 |

0.08 |

0.11 |

0.22 |

|

and |

|

1885 |

1930.8 |

45.8 |

0.05 |

0.10 |

0.13 |

0.25 |

|

including |

|

1925 |

1930.8 |

5.8 |

0.08 |

0.24 |

0.28 |

0.55 |

|

and |

|

1940 |

2050 |

110 |

0.08 |

0.18 |

0.22 |

0.44 |

|

including |

|

1996 |

2014.4 |

18.4 |

0.13 |

0.37 |

0.44 |

0.85 |

|

including |

|

2036 |

2050 |

14 |

0.16 |

0.22 |

0.30 |

0.59 |

|

and |

|

2068 |

2078.1 |

10.1 |

0.04 |

0.09 |

0.11 |

0.22 |

|

KHDDH799 |

Exploration |

No significant intercepts |

|

KHDDH800 |

Exploration |

No significant intercepts |

|

KHDDH801 |

Golden Eagle |

36.6 |

120 |

83.4 |

0.59 |

0.11 |

0.41 |

0.80 |

|

including |

|

57 |

86 |

29 |

1.14 |

0.14 |

0.73 |

1.42 |

|

including |

|

60 |

74 |

14 |

1.90 |

0.14 |

1.11 |

2.18 |

|

including |

|

106 |

114.2 |

8.2 |

0.46 |

0.12 |

0.35 |

0.69 |

|

and |

|

140 |

288.5 |

148.5 |

0.29 |

0.12 |

0.26 |

0.51 |

|

including |

|

201 |

209 |

8 |

0.33 |

0.15 |

0.32 |

0.62 |

|

including |

|

244 |

264 |

20 |

0.72 |

0.18 |

0.55 |

1.07 |

|

KHDDH802 |

Golden Eagle |

35.5 |

285.5 |

250 |

0.37 |

0.12 |

0.31 |

0.60 |

|

including |

|

84 |

180 |

96 |

0.55 |

0.14 |

0.41 |

0.81 |

|

including |

|

206 |

212 |

6 |

0.41 |

0.11 |

0.32 |

0.63 |

|

including |

|

232 |

252 |

20 |

0.39 |

0.15 |

0.35 |

0.68 |

|

KHDDH803 |

Golden Eagle |

36.8 |

244 |

207.2 |

0.20 |

0.11 |

0.21 |

0.42 |

|

including |

|

88 |

98 |

10 |

0.29 |

0.16 |

0.30 |

0.59 |

|

including |

|

170 |

200 |

30 |

0.34 |

0.12 |

0.30 |

0.58 |

|

and |

|

254 |

270.2 |

16.2 |

0.07 |

0.06 |

0.10 |

0.19 |

|

KHDDH804 |

Golden Eagle |

38.1 |

88 |

49.9 |

0.40 |

0.10 |

0.30 |

0.59 |

|

including |

|

38.9 |

58.8 |

19.9 |

0.61 |

0.16 |

0.47 |

0.92 |

|

and |

|

99.25 |

277 |

177.75 |

0.23 |

0.11 |

0.23 |

0.44 |

|

including |

|

113.8 |

178 |

64.2 |

0.42 |

0.14 |

0.35 |

0.69 |

|

including |

|

236 |

244.6 |

8.6 |

0.25 |

0.15 |

0.27 |

0.54 |

|

KHDDH805 |

Golden Eagle |

41.6 |

195 |

153.4 |

0.43 |

0.13 |

0.35 |

0.68 |

|

including |

|

44 |

111 |

67 |

0.67 |

0.15 |

0.50 |

0.97 |

|

including |

|

54 |

62 |

8 |

1.34 |

0.18 |

0.87 |

1.70 |

|

including |

|

54 |

60 |

6 |

1.43 |

0.18 |

0.91 |

1.78 |

|

including |

|

77 |

91 |

14 |

0.81 |

0.21 |

0.62 |

1.22 |

|

including |

|

127 |

133 |

6 |

0.37 |

0.15 |

0.34 |

0.66 |

|

and |

|

267 |

278 |

11 |

0.06 |

0.05 |

0.08 |

0.15 |

|

KHDDH806 |

White Hill |

2 |

146 |

144 |

0.06 |

0.13 |

0.16 |

0.32 |

|

and |

|

156 |

443.4 |

287.4 |

0.07 |

0.18 |

0.21 |

0.41 |

|

including |

|

386 |

443.4 |

57.4 |

0.15 |

0.29 |

0.36 |

0.71 |

|

and |

|

545 |

595 |

50 |

0.94 |

0.25 |

0.73 |

1.42 |

|

including |

|

549 |

571 |

22 |

2.10 |

0.26 |

1.34 |

2.62 |

|

and |

|

779 |

821 |

42 |

0.03 |

0.22 |

0.24 |

0.46 |

|

including |

|

781 |

790 |

9 |

0.05 |

0.53 |

0.56 |

1.09 |

|

KHDDH807 |

White Hill |

295 |

353 |

58 |

0.04 |

0.09 |

0.11 |

0.22 |

|

and |

|

367 |

425 |

58 |

0.04 |

0.12 |

0.14 |

0.27 |

|

including |

|

381 |

385 |

4 |

0.09 |

0.36 |

0.40 |

0.79 |

|

and |

|

435 |

994.7 |

559.7 |

0.07 |

0.23 |

0.27 |

0.53 |

|

including |

|

457 |

477 |

20 |

0.09 |

0.19 |

0.23 |

0.46 |

|

including |

|

487 |

499 |

12 |

0.11 |

0.31 |

0.36 |

0.71 |

|

including |

|

512 |

524 |

12 |

0.10 |

0.26 |

0.31 |

0.61 |

|

including |

|

546 |

555.4 |

9.4 |

0.13 |

0.26 |

0.33 |

0.65 |

|

including |

|

685 |

712 |

27 |

0.05 |

0.26 |

0.28 |

0.55 |

|

including |

|

734 |

747 |

13 |

0.08 |

0.33 |

0.37 |

0.72 |

|

including |

|

761 |

983 |

222 |

0.10 |

0.31 |

0.36 |

0.70 |

|

including |

|

834 |

838 |

4 |

0.22 |

0.55 |

0.66 |

1.28 |

|

and |

|

1004 |

1198 |

194 |

0.06 |

0.19 |

0.22 |

0.42 |

|

including |

|

1034 |

1090 |

56 |

0.10 |

0.25 |

0.30 |

0.59 |

|

including |

|

1180 |

1184 |

4 |

0.08 |

0.43 |

0.46 |

0.91 |

|

KHDDH808 |

White Hill |

238 |

242 |

4 |

0.05 |

0.18 |

0.20 |

0.39 |

|

and |

|

282.5 |

319 |

36.5 |

0.07 |

0.15 |

0.18 |

0.36 |

|

including |

|

305 |

311 |

6 |

0.09 |

0.32 |

0.36 |

0.70 |

|

and |

|

333 |

580.45 |

247.45 |

0.11 |

0.29 |

0.35 |

0.68 |

|

including |

|

341 |

346 |

5 |

0.07 |

0.24 |

0.27 |

0.53 |

|

including |

|

465 |

500 |

35 |

0.09 |

0.31 |

0.36 |

0.70 |

|

including |

|

516 |

580.45 |

64.45 |

0.26 |

0.61 |

0.74 |

1.44 |

|

including |

|

556 |

580.45 |

24.45 |

0.53 |

1.14 |

1.41 |

2.75 |

|

including |

|

558 |

571.8 |

13.8 |

0.70 |

1.64 |

1.99 |

3.90 |

|

and |

|

608 |

626 |

18 |

0.19 |

0.05 |

0.14 |

0.28 |

|

including |

|

620 |

624 |

4 |

0.50 |

0.05 |

0.31 |

0.60 |

|

and |

|

644 |

652 |

8 |

0.19 |

0.03 |

0.12 |

0.24 |

|

and |

|

664 |

672 |

8 |

0.10 |

0.15 |

0.20 |

0.39 |

|

and |

|

750 |

1085 |

335 |

0.08 |

0.25 |

0.30 |

0.58 |

|

including |

|

751.7 |

891 |

139.3 |

0.12 |

0.38 |

0.44 |

0.86 |

|

including |

|

786 |

796 |

10 |

0.13 |

0.54 |

0.61 |

1.19 |

|

including |

|

812 |

818 |

6 |

0.27 |

0.85 |

0.99 |

1.94 |

|

including |

|

918 |

926 |

8 |

0.08 |

0.26 |

0.30 |

0.59 |

|

including |

|

958 |

962 |

4 |

0.08 |

0.29 |

0.33 |

0.65 |

|

including |

|

980 |

989 |

9 |

0.22 |

0.22 |

0.33 |

0.64 |

|

including |

|

1028.8 |

1035 |

6.2 |

0.12 |

0.50 |

0.56 |

1.10 |

|

and |

|

1115 |

1127 |

12 |

0.03 |

0.12 |

0.14 |

0.27 |

|

and |

|

1142 |

1172 |

30 |

0.02 |

0.11 |

0.12 |

0.24 |

|

and |

|

1182 |

1186 |

4 |

0.02 |

0.13 |

0.14 |

0.27 |

|

KHDDH809 |

Exploration |

52.8 |

81 |

28.2 |

0.16 |

0.05 |

0.13 |

0.25 |

|

and |

|

207 |

246 |

39 |

0.13 |

0.09 |

0.15 |

0.30 |

|

including |

|

209 |

220 |

11 |

0.22 |

0.16 |

0.27 |

0.53 |

|

and |

|

256 |

265.7 |

9.7 |

0.19 |

0.09 |

0.19 |

0.36 |

|

And |

|

290 |

295 |

5 |

0.07 |

0.15 |

0.19 |

0.37 |

|

and |

|

328 |

342 |

14 |

0.05 |

0.05 |

0.07 |

0.14 |

|

Assays pending |

|

KHDDH810 |

Altan Shand |

276.1 |

310 |

33.9 |

0.25 |

0.10 |

0.23 |

0.46 |

|

KHDDH811 |

White Hill |

164 |

168 |

4 |

0.11 |

0.10 |

0.16 |

0.31 |

|

and |

|

301.63 |

315 |

13.37 |

0.14 |

0.08 |

0.15 |

0.29 |

|

and |

|

418 |

422 |

4 |

1.81 |

0.09 |

1.02 |

1.99 |

|

KHDDH812 |

White Hill |

No significant intercepts |

Appendix 2: Statements and

Disclaimers

Competent Person Statement

The information in this announcement that

relates to Mineral Resources is based on information compiled by Mr

Robert Spiers, who is responsible for the Mineral Resource

estimate. Mr Spiers is a full time Principal Geologist employed by

Spiers Geological Consultants (SGC) and is a Member of the

Australian Institute of Geoscientists. He has sufficient experience

relevant to the style of mineralisation and type of deposit under

consideration and to the activity he is undertaking to qualify as

the Qualified Person as defined in the CIM Guidelines and National

Instrument 43-101 and as a Competent Person under JORC Code 2012.

Mr Spiers consents to the inclusion in the report of the matters

based on this information in the form and context in which it

appears.

The information in this announcement that

relates to exploration results is based on information compiled by

Dr Andrew Stewart, who is responsible for the exploration data,

comments on exploration target sizes, QA/QC and geological

interpretation and information. Dr Stewart, who is an employee of

Xanadu and is a Member of the Australasian Institute of

Geoscientists, has sufficient experience relevant to the style of

mineralisation and type of deposit under consideration and to the

activity he is undertaking to qualify as the Competent Person as

defined in the 2012 Edition of the Australasian Code for Reporting

Exploration Results, Mineral Resources and Ore Reserves and the

National Instrument 43-101. Dr Stewart consents to the inclusion in

the report of the matters based on this information in the form and

context in which it appears.

Mineral Resources and Ore Reserves

Reporting Requirements

The 2012 Edition of the Australasian Code for

Reporting of Exploration Results, Mineral Resources and Ore

Reserves (the JORC Code 2012) sets out minimum

standards, recommendations and guidelines for Public Reporting in

Australasia of Exploration Results, Mineral Resources and Ore

Reserves. The Information contained in this Announcement has been

presented in accordance with the JORC Code 2012.

The information in this Announcement relates to

the exploration results previously reported in ASX Announcements

which are available on the Xanadu website at:

https://www.xanadumines.com/site/investor-centre/asx-announcements

The Company is not aware of any new, material

information or data that is not included in those market

announcements.

Copper Equivalent

Calculations

The copper equivalent (CuEq) calculation

represents the total metal value for each metal, multiplied by the

conversion factor, summed and expressed in equivalent copper

percentage with a metallurgical recovery factor applied.

Copper equivalent (CuEq) grade values were

calculated using the formula: CuEq = Cu + Au * 0.60049 *

0.86667.

Where Cu - copper grade (%); Au - gold grade

(g/t); 0.60049 - conversion factor (gold to copper); 0.86667 -

relative recovery of gold to copper (86.67%).

The copper equivalent formula was based on the

following parameters (prices are in USD): Copper price

3.4 $/lb; Gold price 1400 $/oz; Copper recovery 90%; Gold recovery

78%; Relative recovery of gold to copper = 78% / 90% = 86.67%.

Forward-Looking Statements

Certain statements contained in this

Announcement, including information as to the future financial or

operating performance of Xanadu and its projects may also include

statements which are ‘forward‐looking statements’ that may include,

amongst other things, statements regarding targets, estimates and

assumptions in respect of mineral reserves and mineral resources

and anticipated grades and recovery rates, production and prices,

recovery costs and results, capital expenditures and are or may be

based on assumptions and estimates related to future technical,

economic, market, political, social and other conditions. These

‘forward-looking statements’ are necessarily based upon a number of

estimates and assumptions that, while considered reasonable by

Xanadu, are inherently subject to significant technical, business,

economic, competitive, political and social uncertainties and

contingencies and involve known and unknown risks and uncertainties

that could cause actual events or results to differ materially from

estimated or anticipated events or results reflected in such

forward‐looking statements.

Xanadu disclaims any intent or obligation to

update publicly or release any revisions to any forward‐looking

statements, whether as a result of new information, future events,

circumstances or results or otherwise after the date of this

Announcement or to reflect the occurrence of unanticipated events,

other than required by the Corporations Act 2001 (Cth) and the

Listing Rules of the Australian Securities Exchange

(ASX) and Toronto Stock Exchange

(TSX). The words ‘believe’, ‘expect’,

‘anticipate’, ‘indicate’, ‘contemplate’, ‘target’, ‘plan’,

‘intends’, ‘continue’, ‘budget’, ‘estimate’, ‘may’, ‘will’,

‘schedule’ and similar expressions identify forward‐looking

statements.

All ‘forward‐looking statements’ made in this

Announcement are qualified by the foregoing cautionary statements.

Investors are cautioned that ‘forward‐looking statements’ are not

guarantee of future performance and accordingly investors are

cautioned not to put undue reliance on ‘forward‐looking statements’

due to the inherent uncertainty therein.

For further information please visit the Xanadu Mines’ Website

at www.xanadumines.com.

Appendix 3: Kharmagtai Table 1 (JORC

2012)

Set out below is Section 1 and Section 2 of

Table 1 under the JORC Code, 2012 Edition for the Kharmagtai

project. Data provided by Xanadu. This Table 1 updates the JORC

Table 1 disclosure dated 8 December 2023.

JORC TABLE 1 - SECTION 1 - SAMPLING

TECHNIQUES AND DATA

(Criteria in this section apply to all succeeding sections).

|

Criteria |

Commentary |

|

Sampling techniques |

- Representative ½

core samples were split from PQ, HQ & NQ diameter diamond drill

core on site using rock saws, on a routine 2m sample interval that

also honours lithological/intrusive contacts.

- The orientation

of the cut line is controlled using the core orientation line

ensuring uniformity of core splitting wherever the core has been

successfully oriented.

- Sample intervals

are defined and subsequently checked by geologists, and sample tags

are attached (stapled) to the plastic core trays for every sample

interval.

- Reverse

Circulation (RC) chip samples are ¼ splits from

one meter (1m) intervals using a 75%:25% riffle

splitter to obtain a 3kg sample

- RC samples are

uniform 2m samples formed from the combination of two ¼ split 1m

samples.

|

|

Drilling techniques |

- The Mineral

Resource Estimation has been based upon diamond drilling of PQ, HQ

and NQ diameters with both standard and triple tube core recovery

configurations, RC drilling and surface trenching with channel

sampling.

- All drill core

drilled by Xanadu has been oriented using the “Reflex Ace”

tool.

|

|

Drill sample recovery |

- Diamond drill

core recoveries were assessed using the standard industry (best)

practice which involves removing the core from core trays;

reassembling multiple core runs in a v-rail; measuring core lengths

with a tape measure, assessing recovery against core block depth

measurements and recording any measured core loss for each core

run.

- Diamond core

recoveries average 97% through mineralisation.

- Overall, core

quality is good, with minimal core loss. Where there is localised

faulting and or fracturing core recoveries decrease, however, this

is a very small percentage of the mineralised intersections.

- RC recoveries

are measured using whole weight of each 1m intercept measured

before splitting

- Analysis of

recovery results vs grade shows no significant trends that might

indicate sampling bias introduced by variable recovery in

fault/fracture zones.

|

|

Logging |

- All drill core

is geologically logged by well-trained geologists using a modified

“Anaconda-style” logging system methodology. The Anaconda method of

logging and mapping is specifically designed for porphyry Cu-Au

mineral systems and is entirely appropriate to support Mineral

Resource Estimation, mining and metallurgical studies.

- Logging of

lithology, alteration and mineralogy is intrinsically qualitative

in nature. However, the logging is subsequently supported by 4 Acid

ICP-MS (48 element) geochemistry and SWIR spectral mineralogy

(facilitating semi-quantitative/calculated mineralogical,

lithological and alteration classification) which is integrated

with the logging to improve cross section interpretation and 3D

geological model development.

- Drill core is

also systematically logged for both geotechnical features and

geological structures. Where drill core has been successfully

oriented, the orientation of structures and geotechnical features

are also routinely measured.

- Both wet and dry

core photos are taken after core has been logged and marked-up but

before drill core has been cut.

|

|

Sub-sampling techniques and sample preparation |

- All drill core

samples are ½ core splits from either PQ, HQ or NQ diameter cores.

A routine 2m sample interval is used, but this is varied locally to

honour lithological/intrusive contacts. The minimum allowed sample

length is 30cm.

- Core is

appropriately split (onsite) using diamond core saws with the cut

line routinely located relative to the core orientation line (where

present) to provide consistency of sample split selection.

- The diamond saws

are regularly flushed with water to minimize potential

contamination.

- A field

duplicate ¼ core sample is collected every 30th sample to ensure

the “representivity of the in-situ material collected”. The

performance of these field duplicates is routinely analysed as part

of Xanadu’s sample QC process.

- Routine sample

preparation and analyses of DDH samples were carried out by ALS

Mongolia LLC (ALS Mongolia), who operates an

independent sample preparation and analytical laboratory in

Ulaanbaatar.

- All samples were

prepared to meet standard quality control procedures as follows:

Crushed to 75% passing 2mm, split to 1kg, pulverised to 85% passing

200 mesh (75 microns) and split to 150g sample pulp.

- ALS Mongolia

Geochemistry labs quality management system is certified to ISO

9001:2008.

- The sample

support (sub-sample mass and comminution) is appropriate for the

grainsize and Cu-Au distribution of the porphyry Cu-Au

mineralization and associated host rocks.

|

|

Quality of assay data and laboratory tests |

- All samples were

routinely assayed by ALS Mongolia for gold

- Au is determined

using a 25g fire assay fusion, cupelled to obtain a bead, and

digested with Aqua Regia, followed by an atomic absorption

spectroscopy (AAS) finish, with a lower detection

(LDL) of 0.01 ppm.

- All samples were

also submitted to ALS Mongolia for the 48-element package ME-ICP61

using a four-acid digest (considered to be an effective total

digest for the elements relevant to the Mineral Resource Estimate

(MRE)). Where copper is over-range (>1% Cu), it

is analysed by a second analytical technique (Cu-OG62), which has a

higher upper detection limit (UDL) of 5%

copper.

- Quality

assurance has been managed by insertion of appropriate Standards

(1:30 samples – suitable Ore Research Pty Ltd certified standards),

Blanks (1:30 samples), Duplicates (1:30 samples – ¼ core duplicate)

by XAM.

- Assay results

outside the optimal range for methods were re-analysed by

appropriate methods.

- Ore Research Pty

Ltd certified copper and gold standards have been implemented as a

part of QC procedures, as well as coarse and pulp blanks, and

certified matrix matched copper-gold standards.

- QC monitoring is

an active and ongoing processes on batch by batch basis by which

unacceptable results are re-assayed as soon as practicable.

- Prior to 2014:

Cu, Ag, Pb, Zn, As and Mo were routinely determined using a

three-acid-digestion of a 0.3g sub-sample followed by an AAS finish

(AAS21R) at SGS Mongolia. Samples were digested with nitric,

hydrochloric and perchloric acids to dryness before leaching with

hydrochloric acid to dissolve soluble salts and made to 15ml volume

with distilled water. The LDL for copper using this technique was

2ppm. Where copper was over-range (>1% Cu), it was analysed by a

second analytical technique (AAS22S), which has a higher upper

detection limit (UDL) of 5% copper. Gold analysis method was

essentially unchanged.

|

|

Verification of sampling and assaying |

- All assay data

QA/QC is checked prior to loading into XAM’s Geobank data

base.

- The data is

managed by XAM geologists.

- The data base

and geological interpretation is managed by XAM.

- Check assays are

submitted to an umpire lab (SGS Mongolia) for duplicate

analysis.

- No twinned drill

holes exist.

- There have been

no adjustments to any of the assay data.

|

|

Location of data points |

- Diamond drill

holes have been surveyed with a differential global positioning

system (DGPS) to within 10cm accuracy.

- The grid system

used for the project is UTM WGS-84 Zone 48N

- Historically,

Eastman Kodak and Flexit electronic multi-shot downhole survey

tools have been used at Kharmagtai to collect down hole azimuth and

inclination information for the majority of the diamond drill

holes. Single shots were typically taken every 30m to 50m during

the drilling process, and a multi-shot survey with readings every

3-5m are conducted at the completion of the drill hole. As these

tools rely on the earth’s magnetic field to measure azimuth, there

is some localised interference/inaccuracy introduced by the

presence of magnetite in some parts of the Kharmagtai mineral

system. The extent of this interference cannot be quantified on a

reading-by-reading basis.

- More recently

(since September 2017), a north-seeking gyro has been employed by

the drilling crews on site (rented and operated by the drilling

contractor), providing accurate downhole orientation measurements

unaffected by magnetic effects. Xanadu have a permanent calibration

station setup for the gyro tool, which is routinely calibrated

every 2 weeks (calibration records are maintained and were

sighted)

- The project

Digital Terrain Model (DTM) is based on 1m

contours from satellite imagery with an accuracy of ±0.1 m.

|

|

Data spacing and distribution |

- Holes spacings

range from <50m spacings within the core of mineralization to

+500m spacings for exploration drilling. Hole spacings can be

determined using the sections and drill plans provided.

- Holes range from

vertical to an inclination of -60 degrees depending on the attitude

of the target and the drilling method.

- The data spacing

and distribution is sufficient to establish anomalism and targeting

for porphyry Cu-Au, tourmaline breccia and epithermal target

types.

- Holes have been

drilled to a maximum of 1,304m vertical depth.

- The data spacing

and distribution is sufficient to establish geological and grade

continuity, and to support the Mineral Resource

classification.

|

|

Orientation of data in relation to geological structure |

- Drilling is

conducted in a predominantly regular grid to allow unbiased

interpretation and targeting.

- Scissor

drilling, as well as some vertical and oblique drilling, has been

used in key mineralised zones to achieve unbiased sampling of

interpreted structures and mineralised zones, and in particular to

assist in constraining the geometry of the mineralised hydrothermal

tourmaline-sulphide breccia domains.

|

|

Sample security |

- Samples are

delivered from the drill rig to the core shed twice daily and are

never left unattended at the rig.

- Samples are

dispatched from site in locked boxes transported on XAM company

vehicles to ALS lab in Ulaanbaatar.

- Sample shipment

receipt is signed off at the Laboratory with additional email

confirmation of receipt.

- Samples are then

stored at the lab and returned to a locked storage site.

|

|

Audits or reviews |

- Internal audits

of sampling techniques and data management are undertaken on a

regular basis, to ensure industry best practice is employed at all

times.

- External reviews

and audits have been conducted by the following groups:

- 2012: AMC

Consultants Pty Ltd. was engaged to conduct an Independent

Technical Report which reviewed drilling and sampling procedures.

It was concluded that sampling and data record was to an

appropriate standard.

- 2013: Mining

Associates Ltd. was engaged to conduct an Independent Technical

Report to review drilling, sampling techniques and QAQC. Methods

were found to conform to international best practice.

- 2018: CSA Global

reviewed the entire drilling, logging, sampling, sample shipping

and laboratory processes during the competent persons site visit

for the 2018 MRE and found the systems and adherence to protocols

to be to an appropriate standard.

|

JORC TABLE 1 - SECTION 2 - REPORTING OF

EXPLORATION RESULTS

(Criteria in this section apply to all succeeding sections).

|

Criteria |

Commentary |

|

Mineraltenementand

landtenurestatus |

- The Project comprises 2 Mining

Licences (MV-17129A Oyut Ulaan and (MV-17387A Kharmagtai):

- Xanadu now owns 90% of Vantage LLC,

the 100% owner of the Oyut Ulaan mining licence.

- The Kharmagtai mining license

MV-17387A is 100% owned by Oyut Ulaan LLC. Xanadu has an 85%

interest in Mongol Metals LLC, which has 90% interest in Oyut Ulaan

LLC. The remaining 10% in Oyut Ulaan LLC is owned by Quincunx (BVI)

Ltd (“Quincunx”).

- The Mongolian Minerals Law (2006)

and Mongolian Land Law (2002) govern exploration, mining and land

use rights for the project.

|

|

Explorationdone

byotherparties |

- Previous exploration at Kharmagtai

was conducted by Quincunx Ltd, Ivanhoe Mines Ltd and Turquoise Hill

Resources Ltd including extensive drilling, surface geochemistry,

geophysics, mapping.

- Previous exploration at Red

Mountain (Oyut Ulaan) was conducted by Ivanhoe Mines.

|

|

Geology |

- The mineralisation is characterised

as porphyry copper-gold type.

- Porphyry copper-gold deposits are

formed from magmatic hydrothermal fluids typically associated with

felsic intrusive stocks that have deposited metals as sulphides

both within the intrusive and the intruded host rocks. Quartz

stockwork veining is typically associated with sulphides occurring

both within the quartz veinlets and disseminated thought out the

wall rock. Porphyry deposits are typically large tonnage deposits

ranging from low to high grade and are generally mined by large

scale open pit or underground bulk mining methods. The deposits at

Kharmagtai are atypical in that they are associated with

intermediate intrusions of diorite to quartz diorite composition;

however, the deposits are in terms of contained gold significant,

and similar gold-rich porphyry deposits.

|

|

Drill holeInformation |

- Diamond drill holes are the

principal source of geological and grade data for the Project.

- See figures in this ASX/TSX

Announcement.

|

|

DataAggregation methods |

- The CSAMT data was converted into

2D line data using the Zonge CSAMT processing software and then

converted into 3D space using a UBC inversion process. Inversion

fit was acceptable, and error was generally low.

- A nominal cut-off of 0.1% CuEq is

used in copper dominant systems for identification of potentially

significant intercepts for reporting purposes. Higher grade

cut-offs are 0.3%, 0.6% and 1% CuEq.

- A nominal cut-off of 0.1g/t AuEq is

used in gold dominant systems like Golden Eagle for identification

of potentially significant intercepts for reporting purposes.

Higher grade cut-offs are 0.3g/t, 0.6g/t and 1g/t AuEq.

- Maximum contiguous dilution within

each intercept is 9m for 0.1%, 0.3%, 0.6% and 1% CuEq.

- Most of the reported intercepts are

shown in sufficient detail, including maxima and subintervals, to

allow the reader to make an assessment of the balance of high and

low grades in the intercept.

- Informing samples have been

composited to two metre lengths honouring the geological domains

and adjusted where necessary to ensure that no residual sample

lengths have been excluded (best fit).

The copper equivalent (CuEq) calculation

represents the total metal value for each metal, multiplied by the

conversion factor, summed and expressed in equivalent copper

percentage with a metallurgical recovery factor applied. The copper

equivalent calculation used is based off the CuEq calculation

defined by CSA Global in the 2018 Mineral Resource Upgrade.Copper

equivalent (CuEq) grade values were calculated

using the following formula:CuEq = Cu + Au * 0.62097 * 0.8235,Gold

Equivalent (AuEq) grade values were calculated

using the following formula:AuEq = Au + Cu / 0.62097 *

0.8235.Where:Cu - copper grade (%)Au - gold grade (g/t)0.62097 -

conversion factor (gold to copper)0.8235 - relative recovery of

gold to copper (82.35%)The copper equivalent formula was based on

the following parameters (prices are in USD):

- Copper price - 3.1 $/lb (or 6834

$/t)

- Gold

price - 1320

$/oz

- Copper recovery - 85%

- Gold recovery - 70%

- Relative recovery of gold to copper

= 70% / 85% = 82.35%.

|

|

Relationship between mineralisationon

widthsand

interceptlengths |

- Mineralised structures are variable

in orientation, and therefore drill orientations have been adjusted

from place to place in order to allow intersection angles as close

as possible to true widths.

- Exploration results have been

reported as an interval with 'from' and 'to' stated in tables of

significant economic intercepts. Tables clearly indicate that true

widths will generally be narrower than those reported.

|

|

Diagrams |

- See figures in the body of this

ASX/TSX Announcement.

|

|

Balancedreporting |

- Resources have been reported at a

range of cut-off grades, above a minimum suitable for open pit

mining, and above a minimum suitable for underground mining.

|

|

Othersubstantiveexplorationdata |

- Extensive work in this area has

been done and is reported separately.

|

|

FurtherWork |

- The mineralisation is open at depth

and along strike.

- Current estimates are restricted to

those expected to be reasonable for open pit mining. Limited

drilling below this depth (-300m RL) shows widths and grades

potentially suitable for underground extraction.

- Exploration on going.

|

JORC TABLE 1 - SECTION 3 - ESTIMATION

AND REPORTING OF MINERAL RESOURCES

Mineral Resources are not reported so this is

not applicable to this Announcement. Please refer to the Company’s

ASX Announcement dated 8 December 2023 for Xanadu’s most recent

reported Mineral Resource Estimate and applicable Table 1, Section

3.

JORC TABLE 1 - SECTION 4 - ESTIMATION

AND REPORTING OF ORE RESERVES

Ore Reserves are not reported so this is not

applicable to this Announcement.

|

AUSTRALIA c/o Company Matters Pty Limited Level

12, 680 George Street Sydney NSW 2000 T: +612 8280 7497 |

|

MONGOLIA Suite 23, Building 9B Olympic St,

Sukhbaatar District Ulaanbaatar, Mongolia T: +967 7012 0211 |

|

Xanadu Mines Ltd ACN 114 249

026www.xanadumines.com |

Photos accompanying this announcement are available at:

https://www.globenewswire.com/NewsRoom/AttachmentNg/d0c0d20a-a92b-4ff6-80dd-08499758aa40

https://www.globenewswire.com/NewsRoom/AttachmentNg/e2b8bd8f-647f-4fb7-9245-c52232eb696e

https://www.globenewswire.com/NewsRoom/AttachmentNg/f97eb87c-ab0e-4973-9650-6cb46de6308b

https://www.globenewswire.com/NewsRoom/AttachmentNg/84c8967f-62f7-45a1-ab8a-3995f474071d

https://www.globenewswire.com/NewsRoom/AttachmentNg/e85dfd4d-a546-4c1d-8f88-75510896144b

https://www.globenewswire.com/NewsRoom/AttachmentNg/753a6653-2653-4e7c-9d2d-552c0c2d5ce4

https://www.globenewswire.com/NewsRoom/AttachmentNg/81c8fa69-6222-4e06-b836-f3528c6b94ba

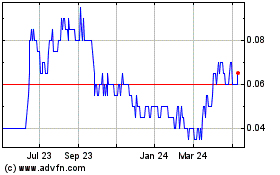

Xanadu Mines (TSX:XAM)

Historical Stock Chart

From Dec 2024 to Jan 2025

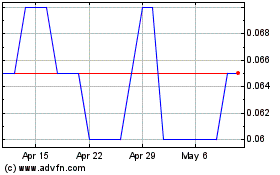

Xanadu Mines (TSX:XAM)

Historical Stock Chart

From Jan 2024 to Jan 2025