(TSX-V: ILI) Effective immediately, Guy Farebrother, currently

serving as Chairman of the Board and Vice President of Operations,

will be assuming the leadership role of President & CEO to

guide the company through a corporate and management restructuring.

Guy will be stepping down as Chairman but will remain on as a

Director. Tom Milley, currently serving as a Director, will assume

the role as Chairman. Serge Bonnet, will be stepping down as

President and will assume the role of Chief Operating Officer and

will continue as a Director of the company. Going forward Serge

will focus on the sales growth and daily operations associated with

CBM, and drive new sales for the PressureTrax and SandTrax

businesses. Serge will also take on the role for Thermoflex tubing

sales in the geographical area of Gillette, Wyoming including North

and South Dakota as well as Montana and international markets,

excluding Mexico as ILI currently has representation in this area.

Ed Michielsen and John MacMillan will both continue on as

Directors.

As part of the reorganization a number of measures are being

taken to reduce costs, streamline operations, and focus on the

expansion of current projects that afford the greatest growth

potential. Current market conditions have dictated that the prudent

course of action is necessary to preserve cash. By focusing on

these redundancies management believes the company will increase

efficiencies without impacting operations or timelines. Management

remains committed to increasing shareholder value.

NEW APPOINTMENT

ILI is pleased to announce the appointment of Shamel Costandy as

Chief Financial Officer. Shamel has 17 years of business experience

including 7 years in public practice, 7 years in the pharmaceutical

industry and 3 years in the oil and gas industry. Prior to joining

ILI Technologies, he was the Financial Controller of Stem Cell

Therapeutics, a publicly traded Canadian biotech company based in

Calgary, AB for almost 4 years. His work experience throughout his

career was mainly with multinationals who are leaders in their

business including companies like BG Group (a leading UK based

player in the global energy market), Organon Nederland BV (a

leading Dutch based pharmaceutical -- now a subsidiary of

Schering-Plough) and he spent 7 years in public practice with

Deloitte. Shamel is a licensed US CPA, and a Certified Internal

Auditor.

OPERATIONS UPDATE

PRESSUREtrax(TM)

The PressureTrax is a temperature compensated, battery powered,

stand-alone recording system that can record pressure, temperature,

rate, and time simultaneously. The system operates across the

temperature range of -40C to +85C and recorded data can be

downloaded from the sensor memory and/or displayed on a remote

computer in real time. PressureTrax has been awarded CSA Class 1,

Group C & D certification for operation in an Intrinsically

Safe environment.

In a declining oil and gas market, PressureTrax will remain the

product of choice for clientele seeking to achieve significant cost

savings to their operating budgets.

SANDtrax (patented)

The SandTrax instrument is a non-intrusive measurement device

that records acoustical energy created when fluids and particles

impinge the inside wall of the pipe. The instrument then filters

the frequencies with a digital signal processor to display only the

signals created by the particles in the fluid stream. ILI is

currently working with the Alberta Research Council (ARC) to

develop a next generation sensor for our patented SandTrax

monitoring system. Currently, the company has approved the initial

prototype and is waiting on the initial run of sensors to begin

field testing. The company has also completed the initial CSA

application process for having the overall system certified for

Intrinsically Safe operation. This will allow the SandTrax to be

used in any hazardous location meeting Class 1, Groups C & D

requirements. These areas include offshore platform, production

facilities, and general worldwide acceptance for oilfield areas

that the company can't currently access.

The typical application at this time is fracturing flow back and

well cleanout applications which do not require IS certification.

In addition to the hazardous location acceptance, the new

electronics package will substantially decrease power requirements

resulting in much longer run times. In order to fully utilize this

extended run time we have increased our internal memory capacity by

16 times and our download speeds by 12 times while extending our

cable lengths from 200 feet to 2,000 feet.

CBM Pumps & Services

CBM Pumps & Services, a division of ILI operating in

Gillette, Wyoming, supplies and services a wide variety of ESP

solutions. We offer a "hands on" approach to each and every well to

ensure the ESP is running at the highest efficiency. With a wide

variety of applications, our electric submersible pumps can provide

a cost effective lift solution. Our ESP's are multistage

centrifugal pumps designed for durability and long run times. In

wells with declining reservoir pressure or even in sand producing

wells, an ESP pump can provide an economical lift method versus

traditional production methods.

CBM continues to be the foundation of ILI's revenue base and has

grown exponentially year over year and is geographically positioned

to take advantage of the expected growth in the geographic area

including North and South Dakota as well as Montana. Recent oil and

gas discoveries as well as ongoing production in these areas have

proven that our products are being highly sought after for

dewatering applications and low volume oil production.

CBM has received new orders for pump packages in Columbia. These

pumps have been built to specifications and ILI is waiting on

shipment instructions. This new business has the potential of

leading up to a multi-well program and opens new doors for the ESP

business in international markets. ILI is pleased with the progress

of the CBM division and maintains that the ESP business will

continue to be a stable revenue base for the company.

Thermoflex Pipe�

ILI has acquired the exclusive rights to distribute Thermoflex

pipe in 7 of the U.S. States, 3 of the Western Provinces in Canada,

Mexico and China. Thermoflex pipe is a revolutionary new flexible

piping system that can be applied in areas where only steel piping

could be used in the past. Thermoflex pipe uses a multi-layer

design with mixed plastics to achieve far superior performance

compared to traditional flexible pipe and is ideally suited for

high pressure, high temperature applications especially when

paraffins are present. Typical applications include gathering

lines, velocity strings and liners. No cathodic protection or

coating is required and installation costs are significantly less

than steel.

Thermoflex tubing replaces steel pipe in many oil and gas

applications. The world market for steel tubing supplied to the oil

and gas industry is estimated at over $20 billion per year. The

price of steel tubing supplied to the oil and gas industry has

soared 80% since the beginning of 2008. Over the years, attempts

have been made to replace steel pipe with fiberglass or PVC but

these attempts have often failed because the materials are usually

unable to withstand the heat and pressure requirements for down

hole applications or flow lines.

Performance Advantages

-- Thermoflex pipe has 30% reduction in pressure drop vs. steel

-- Superior Corrosion Resistance in CO2, H2S Environments

-- Resistant to Paraffin and Salt Adhesion

-- 100 times less the relative roughness of steel

-- No cathodic protection or coating required

-- Service Applications to 250F

Installation Advantages

-- 1/10th the weight of steel, long continuous runs, lower installation

costs compared to steel

-- Pig cable pull through -- capable of multiple mile runs

-- Highly Flexible, easy to handle

-- Utilizes existing installation equipment

Over Our Competitors

-- Higher temperature and pressure applications

-- Thermoflex only down hole pipe accepted for use by industry

-- Longer pipe life, rugged, proven in extreme conditions

-- Fortron lining will not corrode, is resistant to paraffins, heat

resistant to 250 degrees

-- Low permeation, can withstand hydrocarbon and sour gas environments

Thermoflex in Mexico

Over 70% of Mexico's pipeline production has been depleted as a

result of corrosive related issues. The Mexican oil investment

budget has increased to $21 billion for 2008 and there is an

immediate need for over 7,000 kms of pipe as per recent

publications in Mexico. Highest priority has been given on

upgrading oilfields and installing new pipelines and Pemex has

mandated for alternative technologies and the use of non-metallic

pipe in lieu of steel due to availability, costs and faster

installation procedures.

In the south region to date, ILI has successfully installed over

65 kms of pipe and is actively pursuing new business. In

Villaheromosa, the company recently delivered 7,000 meters of 4.5

inch Thermoflex tubing and is currently making arrangements for the

installation of that pipe.

In the north region, ILI has recently installed a high pressure

line adopting strict standards imposed by Pemex and is pleased to

say that the test was a complete success. Pemex is currently

evaluating the test results as well as the technology and is

requesting updated information to satisfy their requirements. As a

result of the timelines involving the process to meet these

requirements ILI does not expect any new orders for the remainder

of this year but remains highly optimistic about new business in

2009.

On March 30, 2007, ILI announced an order for Thermoflex tubing

business in the amount of US$9.5 million. Due to discrepancies

associated with the bidding process as it relates to Mexican

contractors and other aspects of the project to fulfill other

requirements associated with the tender, this project is being put

back on the market for re-tender. The company does not expect this

bidding process to be completed in the near future.

ILI is also awaiting approval to proceed with a test well in the

Reynosa area for down hole Thermoflex tubing that will afford the

company additional opportunities. The tubing has already delivered

to a major oil and gas service company and is expected to start

installation in the near future. Upon successful completion of the

installation, the test well will be monitored for approximately 3

to 6 months before any new orders are expected. This down hole

technology is already proven in other areas of company business and

ILI anticipates that this will evolve into a multi-well program in

the future.

To date, ILI has quoted on over $100 million dollars in

Thermoflex business, and while these quotes do not guarantee firm

orders, the company remains optimistic that the product will prove

to be a viable replacement for steel in Mexico. The company

believes there is a strong case for the Thermoflex product and is

working diligently in the pursuit of new sales in Mexico.

Thermoflex in UAE

ILI has received an order for CDN$200,000 to supply Thermoflex

pipe for a pull through pipe project in Dubai. This pipe is

currently being manufactured and is expected to be delivered in the

near future. ILI will provide on-site expertise throughout the

product installation period. This order opens doors to new

international business.

Thermoflex in China

Through ILI's exclusive agents the Thermoflex tubing product was

recently presented to China National Petroleum (CNCP) Business

Development. The company has spent much time and investment

marketing the Thermoflex tubing product throughout China and is

working closely with its agents to develop a program for sales and

distribution of our products.

Thermoflex in Canada

ILI has successfully installed Thermoflex down hole pipe in 16

wells with a major oil and gas producer resulting in reduced

paraffins and increased production. Installations continue as part

of this multi-well program.

The company has been working diligently to obtain ERCB

certification for the Thermoflex pipe for use in Canada and is

complying with the Energy Resources and Conservation Board

procedures for testing. To date, ILI has performed the following

tests in accordance with standards imposed and is close to

completion.

-- Successfully completed 1st phase 100 hr test

-- Successfully completed 2nd phase 1,000 hr test

-- Currently undergoing 10,000 hr test with ERCB

This test is expected to be complete by the 2nd week in

November

After the 10,000 hour test requirements have been completed, the

findings will be sent to the ERCB for evaluation after which time

the ERCB will notify ILI of the next step towards achieving

certification. There is no specific timeline in place for this

certification process and every product is evaluated on its own

merits.

In conclusion, ILI is gaining traction in its business divisions

and has made great progress in the past few months in advancing our

commercially accepted products. In the near term, the company will

focus its efforts on expense reduction, streamlining operations,

finance and sales growth.

About us

ILI Technologies manufactures and markets a line of products for

the international oil and gas industry. The company provides pumps,

flexible pipe and specialized measuring equipment to fulfill the

needs of the oil and gas production industry.

ILI's immediate focus is the expansion of an innovative new

flexible piping system, Thermoflex�. Through its multilayer

extrusion technology, the product combines different engineered

polymers and fibre reinforcement to create products to withstand

corrosive environments, enhance production rates and reduce the

installed costs for wells and gathering lines. Thermoflex� has

unique benefits that make it more desirable than traditional steel

pipe.

The TSX Venture Exchange has not reviewed and does not accept

responsibility for the adequacy or accuracy of this release.

We seek Safe Harbor.

Distributed by Filing Services Canada and retransmitted by

Marketwire

For further information, please contact: Guy Farebrother

President ILI Technologies (2002) Corp Phone: (403) 543-0060 Fax:

(403) 543-0069 E-mail: Email Contact Website:

http://www.ilitech.com

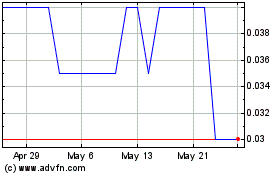

Imagine Lithium (TSXV:ILI)

Historical Stock Chart

From Apr 2024 to May 2024

Imagine Lithium (TSXV:ILI)

Historical Stock Chart

From May 2023 to May 2024