Sherwood Copper Corporation (TSX VENTURE:SWC)(TSX VENTURE:SWC.DB) today

announced results of an independent preliminary economic assessment ("PEA") for

its high grade Kutcho copper project in NW British Columbia. This study

significantly simplifies development approach to the project, but only evaluates

the development of part of one of the three identified mineral deposits at

Kutcho. However, the PEA lays out several opportunities for enhanced project

economics, a number of which Sherwood is already evaluating as part of its

on-going work program.

"The completion of the preliminary economic assessment for the high grade Kutcho

copper project is just the first step in Sherwood's on-going reassessment of the

project's potential," said Stephen Quin, President & CEO. "This study evaluates

the potential for the development of a smaller, less capital intensive open pit

mining operation on a portion of the Main deposit that can be developed

relatively quickly. We are now pursuing two parallel tracks to enhance this base

case option by evaluating: (a) a number of opportunities identified within the

study that could significantly enhance the economics of the project as defined,

and (b) the potential of increasing the production and mine life by

incorporating some of the more than 50% of the project mineral resources not

considered in this study," he said. "The most significant upside opportunities

currently being evaluated are increasing the tonnes and grade of material to be

processed and improving metallurgical recoveries beyond those assumed in the

study. To this end, we have a major drill program underway at Kutcho to not only

better define the highest grade, closest to surface portion of the Main deposit,

but to provide sample material for extensive metallurgical testing designed to

evaluate opportunities for enhanced metal recoveries."

Using the PEA as a platform, Sherwood intends to re-engage the regulatory

agencies and advance the Kutcho copper project through the permitting process.

With extensive baseline data, Sherwood has commenced drafting an Environmental

Assessment for submission in the third quarter of 2008. In parallel with the

regulatory process, Sherwood aims to continue to actively engage the Tahltan and

Kaska First Nations in a consultation process in order to gain their support for

the advancement of this project.

"Given the decline of active mining in NW British Columbia and the uncertainty

surrounding the potential development of a number of other projects in the

region, the high grade Kutcho copper project stands out as a mine that could be

advanced to production relatively quickly, assuming appropriate support and

approvals for the project," said Mr. Quin. "Our approach to the development of

the project should significantly reduce the environmental footprint of the

project versus previous proposals and should simplify the long-term abandonment

and restoration of the site post-closure," he said. "In addition, the smaller

scale of the proposed development may result in an extended mine life, once the

remainder of the mineral resources not considered in this study are evaluated

and, if warranted, incorporated into an expanded project."

Sherwood intends to issue an updated PEA in the fall of 2008 that would

incorporate the results of the 2008 infill drilling, results from initial

metallurgical testing currently in process and incorporation of other mineral

resources not considered in the PEA. "Our approach to Kutcho will be similar to

that used with our Minto Mine, where we relentlessly pursue every opportunity

for increasing the value of the asset we own," said Mr. Quin. "We aim to

evaluate each opportunity and drive it to ground in parallel with our

feasibility and permitting process, so that there are regular, incremental

increases in the value of the asset."

Highlights

The PEA lays out the basis for the development of an open pit mining operation

based on mining of the Main deposit only. Highlights of the PEA, as compared to

previously announced plans by prior owners, include the following (note that "M"

at the end of a number means "millions" and "K" means "thousands"):

- Open pit mining of approximately 63% of the Main deposit only, comprising

10.5M tonnes of indicated mineral resource at an average grade of 1.73% copper,

2.35% zinc, 0.27g/t gold and 26.3g/t silver, containing over 400M lbs of copper

and 540M lbs of zinc, 90,000oz of gold and 8.9M oz of silver plus some minor

amounts of inferred mineral resource; deeper portions of the Main deposit and

all of the Sumac and Esso deposits which, combined, total more than 50% of the

total resources at Kutcho remain to be evaluated in subsequent studies;

- Open pit redesigned to optimize grade and strip ratios over the mine life,

with an overall strip ratio of 5.1:1 waste:material processed versus 6.7:1 in

prior studies;

- Processing 4,000 tonnes per day ("tpd") vs. prior plans for 6,000tpd, with

recoveries of 84% for copper, 74% for zinc and 50% and 52% for gold and silver,

respectively;

- Average annual payable production of 45M lbs of copper, 48M lbs of zinc,

5,600oz of gold and 584,000oz of silver over a 7.3 year mine life;

- Life of mine payable production of 331M lbs of copper, 348M lbs of zinc,

41,000oz of gold and 4.2M oz of silver over an a 7.3 year mine life, with

potential for additional life from underground mining of the remaining 6M tonnes

in the Main deposit, as well the Esso and, possibly, portions of the Sumac

deposits in later years;

- Production of separate copper and zinc concentrates, averaging 30.3% copper

and 55% zinc, respectively, with payable the precious metals reporting to the

copper concentrates;

- Average unit operating costs of $52.49 per tonne yielding cash costs of $1.70

to $1.72 per pound of copper before by-product credits and $0.82 to $0.93 per

pound of copper after by-product credits;

- Pre-production capital of $183.3M, versus $299M in the pre-feasibility study

prepared by prior owners;

- Pre-tax NPV of $300M to $52M and pre-tax IRR's of 54% to 19% based on metal

prices ranging from the recent forward curve (gold and silver prices kept flat)

to a 30% discount to the forward curve, giving payback in 1.5 to 3.0 years;

- Approximately 50% reduction in the aerial extent of disturbance;

- Switch to compacted and encapsulated dry-stack tailings and buffered waste

dumps for any potentially acid generating waste rock. The dry-stack approach to

tailings disposal would eliminate the need for a conventional tailings dam

across Andrea Creek and would significantly reduce the environmental impact of

the project.

The PEA represents an interim update on the Kutcho Project with mineral resource

estimates as of the end of 2007 and costs as of May 2008 and only addresses

mining of a portion of the Main deposit. However, the PEA identifies a number of

significant value enhancement opportunities that suggest that additional value

could be extracted from the Kutcho Project. Sherwood will continue to pursue the

crystallization of these enhancements, including possible extraction of some or

all of the remaining mineral resources in the Main deposit, Esso deposit and

Sumac deposit, possibly by underground methods. These and other opportunities

will be addressed in subsequent studies.

Basis of Preliminary Economic Assessment

In May 2008, Sherwood completed the acquisition of Western Keltic Mines Ltd. and

its Kutcho Project, so that the Kutcho Project is 100% owned by Kutcho Copper

Corp. ("KCC"), a wholly owned subsidiary of Sherwood. On the basis of the then

impending acquisition, Sherwood commissioned the independent PEA completed under

the supervision of SRK Consulting (Canada) Inc. ("SRK"). While compiled by SRK,

the PEA relies extensively on the contributions of the following companies; JDS

Energy and Mining Inc., Rescan Environmental Services Ltd., Techpro, Sacre-Davey

Engineering and Kirkham Geosystems Ltd.

The PEA only evaluated open pit mining of a portion of one of the three known

deposits comprising the Kutcho Project, known as the "Main" deposit. The Main

deposit is a tabular body of high grade copper-zinc mineralization that outcrops

on surface. West of the Main deposit lies the poorly drilled Sumac deposit and,

beyond that, the Esso deposit, the highest grade of the three know deposits.

It is envisioned that, based on the results of this study, KCC will seek permits

and support to develop the Kutcho Project as set out in the PEA while, in

parallel, advancing the project through completion of a feasibility study and

evaluating options to increase the total quantity of material to be mined and

processed by considering the potential for mining the remaining portions of the

Main deposits, as well as the Esso and Sumac deposits.

Mineral Resources

The mineral resource estimate for the Main deposit at Kutcho was completed by

Garth Kirkham, P.Geo., of Kirkham Geosystems Ltd., using industry standard

methods that conform with National Instrument 43-101 and utilizing MineSight(TM)

Software. The resource estimate for the Main deposit was based upon historical

data from 221 Main deposit drill holes supplied by KCC.

Kutcho PEA - Mineral Resource Estimate (@ 0.75 %CuEq cut-off) - Main

Deposit Only

--------------------------------------------------------------------------

In situ Grade Contained Metal

---------------------------------------------------

% % g/t g/t Cu Zn Ag Au

Class Tonnes Cu Zn Ag Au (Mlb) (Mlb) (Moz) (000's oz)

--------------------------------------------------------------------------

Indicated 17,285,000 1.56 2.12 26.1 0.29 594.5 807.9 14.5 161.2

--------------------------------------------------------------------------

Inferred 367,000 1.62 1.77 23.6 0.13 13.1 14.3 0.3 1.5

--------------------------------------------------------------------------

Mine Plan

The Main deposit is proposed to be developed as an open pit that would produce a

total of 10.7 million tonnes (Mt) of mill feed and 54.3 Mt of waste over an

initial 7.3-year mine operating life. Additional mineral resources remain within

the Main deposit, as well as those in the Sumac and Esso deposits, that could

potentially support an extended life. The life-of-mine ("LOM") plan for the Main

deposit open pit focuses on achieving the required mill feed production rate,

while balancing grade and strip ratios. Due to the susceptibility of the Kutcho

mineralization to oxidation, minimal stockpile and blending capacity is assumed

in the PEA.

Mine design for the Main deposit open pit was initiated with the development of

a Net Smelter Return ("NSR") model. The model included estimates of metal

prices, exchange rate, mining dilution, mill recovery, concentrate grade

smelting and refining payables and costs, freight and marketing costs and

royalties. The NSR model was based on a 5m x 5m x 5m block size. The model was

then used with the Gemcom Whittle - Strategic Mine Planning(TM) ("Whittle")

software to determine the optimal mining shell. Mine planning and scheduling was

then conducted on the optimal pit shell with the use of MineSight(TM) software

and mineral resources were estimated (see table below). A $31/t NSR cut-off was

used within the planned pit.

Kutcho PEA - Open Pit Life-of-Mine Mineral Resource (@ $31/t NSR cut-off)

- Main Deposit Only

--------------------------------------------------------------------------

In situ Grade Contained Metal

---------------------------------------------------

% % g/t g/t Cu Zn Au Ag

Class Tonnes Cu Zn Au Ag (Mlb) (Mlb) (oz) (oz)

--------------------------------------------------------------------------

Indicated 10,513,000 1.73 2.35 0.27 26.3 400.7 543.7 90,400 8,900,000

--------------------------------------------------------------------------

Inferred 163,000 1.67 1.93 0.11 22.16 6.0 6.9 600 116,100

--------------------------------------------------------------------------

The mining sequence was divided into eight phases designed to maximize grade,

reduce pre-stripping requirements, while providing the required mill feed

production per period. The Main pit is most economical when phases are mined

concurrently. The LOM mine production schedule is summarized in the table below.

Kutcho PEA -Life of Mine Production Schedule - Main Deposit Only

---------------------------------------------------------------------------

Production Year

Pre- ---------------------------------------------

Parameter Units prod 1 2 3 4 5 6 7 8 Total

---------------------------------------------------------------------------

Mineralized Mt - 1.46 1.46 1.46 1.46 1.46 1.46 1.46 0.5 10.7

rock mined(i)

---------------------------------------------------------------------------

Waste mined Mt 0.6 5.0 8.6 8.5 12.4 10 6.0 2.8 0.3 54.3

---------------------------------------------------------------------------

Strip ratio Wt:Ot - 3.4 5.9 5.8 8.5 6.8 4.1 1.9 0.8 5.1

---------------------------------------------------------------------------

Cu grade % Cu - 1.83 1.74 1.93 1.72 1.65 1.53 1.75 1.65 1.73

---------------------------------------------------------------------------

Zn grade % Zn - 2.83 2.38 2.65 2.22 2.07 1.96 2.39 2.06 2.34

---------------------------------------------------------------------------

Au grade Au g/t - 0.29 0.34 0.32 0.26 0.21 0.2 0.24 0.26 0.27

---------------------------------------------------------------------------

Ag grade Ag g/t - 26.6 28.7 29.8 26.1 23.8 23.4 24.9 28.6 26.3

---------------------------------------------------------------------------

(i) Since this is a PEA and incorporates inferred mineral resources (1.5%

of the total), this material cannot be quantified as a reserve under

NI 43-101.

Waste Management

Tailings from the mill will be sent to the proposed dry-stack location to the

east of the mill facility. The approach for dry-stacking will be similar to that

used by Sherwood at its Minto Mine in the Yukon, with the addition of berms to

retain and encapsulate the tailings for permanent abandonment. Non-potentially

acid generating ("non-PAG") waste rock from the Main pit will be deposited in a

number of dumps adjacent to the pit, as well as in buffered containments for the

dry-stack tailings. A separate waste dump has been designed for the potential

acid generating ("PAG") rock that will be extracted from the Main pit.

Backfilling into previously mined out areas would offer an improvement in the

waste haulage cycle for the trucking of waste out of the main pit and will be

considered in future studies.

Processing

The mineralogy of the Kutcho deposit is fine grained and requires a relatively

fine primary grind followed by a very fine regrind to produce copper and zinc

concentrates at reasonable recoveries. The mineralized zone rock has been

determined to be soft and obtaining a fine grind is not considered to be an

issue. The flotation circuit is expected to be a standard copper-zinc circuit

with copper being recovered followed by zinc flotation. Both copper and zinc

rougher concentrates will be reground to approximately 10 microns followed by

three stages of cleaning. Copper concentrate produced will contain sufficient

zinc to likely incur a smelter penalty. The penalty has been assumed to be

$4.00/dmt of concentrate. The copper concentrate is expected to be 30.3% copper.

The sphalerite is low in iron and the grade of the concentrate will be high at

55% zinc. Recoveries are expected to be 82-84% for copper and 72-74% for zinc.

The recovery assumptions used in this report are shown in the table below.

Metallurgical test work is ongoing to refine the fineness of primary grind and

the reagent scheme. Variability testing will refine the metallurgical response

with depth and will refine annual production of metals. The current drill

program is an opportunity to refine the characteristics of the mineralization

with respect to bornite/chalcopyrite ratios, degree of dissemination and pyrite

content and relate these characteristics to metallurgical response.

Kutcho PEA - Assumed Metallurgical Parameters Used in Cash Flow - Main

Deposit Only

--------------------------------------------------------------

Assumed Assumed Cu Assumed Zn

Metal recovery concentrate grade concentrate grade

--------------------------------------------------------------

Copper 84% 30.30%

--------------------------------------------------------------

Zinc 74% 55%

--------------------------------------------------------------

Gold 50% 4 g/t

--------------------------------------------------------------

Silver 52% 330 g/t

--------------------------------------------------------------

Operating & Capital Costs

Operating and capital expenses were derived from a number of sources. Many costs

were factored from Sherwood's Minto Mine in the Yukon. The Minto Mine is also a

small high-grade deposit with many similarities to the Kutcho design and,

therefore, served as a valuable reference of a small, northern open pit base

metal mine and mill. Capital and operating expense estimates are summarized in

the tables below.

Kutcho PEA - Operating Cost Assumptions & Estimates - Main Deposit Only

----------------------------------------------------

Parameter Unit Cost Unit

----------------------------------------------------

Mining cost 1.64 C$/t rock

----------------------------------------------------

Mining cost 9.87 C$/t milled

----------------------------------------------------

Site Services & G&A cost

----------------------------------------------------

Labour 4.48 C$/t milled

----------------------------------------------------

Equipment 0.68 C$/t milled

----------------------------------------------------

Materials 14.02 C$/t milled

----------------------------------------------------

Expenses 0.94 C$/t milled

----------------------------------------------------

Contingency 2.01 C$/t milled

----------------------------------------------------

Total Services and G&A 22.13 C$/t milled

----------------------------------------------------

Milling cost

----------------------------------------------------

Labour 4.04 C$/t milled

----------------------------------------------------

Equipment 0.62 C$/t milled

----------------------------------------------------

Materials 7.48 C$/t milled

----------------------------------------------------

Expenses 0.37 C$/t milled

----------------------------------------------------

Contingency 1.25 C$/t milled

----------------------------------------------------

Total Milling 13.76 C$/t milled

----------------------------------------------------

Capital leases (total) 5.0 C$/t milled

----------------------------------------------------

Royalties 2% NSR

----------------------------------------------------

Kutcho PEA - Capital Cost Estimates - Main Deposit Only

--------------------------------------------

Initial Capital

Item (Millions)

--------------------------------------------

Site Infrastructure $8.80

--------------------------------------------

Mining $7.10

--------------------------------------------

Process Plant $72.50

--------------------------------------------

Services $2.30

--------------------------------------------

Ancillary Buildings $5.90

--------------------------------------------

Construction Camp Costs $6.10

--------------------------------------------

Off site Infrastructure $18.00

--------------------------------------------

Total Direct Capital Costs $120.70

--------------------------------------------

Indirect Capital Costs $38.70

--------------------------------------------

Total Project $159.40

--------------------------------------------

Contingency @ 15% $23.90

--------------------------------------------

G R A N D T O T A L $183.30

--------------------------------------------

In addition to the capital in the table above, there is another $43.1M in

capital equipment that will be leased over a seven-year period. Approximately

50% of the leased capital is mobile equipment for the open pit mine.

Production

The following sets out the copper, zinc, gold and silver in concentrates and

estimated payable metal detailed in the PEA.

Kutcho PEA - Life-of-Mine Metal Production Forecast - Main Deposit Only

------------------------------

Year

--------------------------------------------------------------

Item Unit 1 2 3 4

--------------------------------------------------------------

Copper in cons lb ('000) 49,400 47,100 52,300 46,400

--------------------------------------------------------------

Zinc in cons lb ('000) 67,500 56,700 63,400 52,800

--------------------------------------------------------------

Gold in cons oz ('000) 6.8 8.0 7.4 6.0

--------------------------------------------------------------

Silver in cons oz ('000) 653 705 734 643

--------------------------------------------------------------

Conc. grade % Cu 30.3 30.3 30.3 30.3

--------------------------------------------------------------

Payable copper(i) lb ('000) 47,700 45,400 50,500 44,800

--------------------------------------------------------------

Payable zinc(i) lb ('000) 57,400 48,200 53,900 44,900

--------------------------------------------------------------

Payable gold oz Au ('000) 6.1 7.2 6.7 5.4

--------------------------------------------------------------

Payable silver oz Ag ('000) 588 634 661 578

--------------------------------------------------------------

------------------------------

Year

-----------------------------------------------------------------------

Item Unit 5 6 7 8 Total

-----------------------------------------------------------------------

Copper in cons lb ('000) 44,600 41,500 47,500 14,700 343,000

-----------------------------------------------------------------------

Zinc in cons lb ('000) 49,200 46,700 57,100 16,100 409,000

-----------------------------------------------------------------------

Gold in cons oz ('000) 4.9 4.7 5.7 2.0 45.5

-----------------------------------------------------------------------

Silver in cons oz ('000) 585 574 613 232 4,739

-----------------------------------------------------------------------

Conc. grade % Cu 30.3 30.3 30.3 30.3 30.3

-----------------------------------------------------------------------

Payable copper(i) lb ('000) 43,100 40,000 45,800 14,100 331,000

-----------------------------------------------------------------------

Payable zinc(i) lb ('000) 41,800 39,700 48,500 13,700 348,000

-----------------------------------------------------------------------

Payable gold oz Au ('000) 4.4 4.2 5.1 1.8 41

-----------------------------------------------------------------------

Payable silver oz Ag ('000) 527 517 552 208 4,265

-----------------------------------------------------------------------

(i) Copper, gold and silver are payable only within the Cu concentrate.

Zn is payable only within the Zn concentrate.

As noted above, additional smoothing of production is planned post-PEA as part

of an on-going process of open pit optimization, as well as evaluating options

for extending the mine life by incorporating additional mineral resources

defined on the Kutcho Project but not considered in the PEA, including the

balance of the Main deposit and those in the Esso and Sumac deposits.

Economic Analysis

The economic assessment in the PEA is preliminary in nature and uses inferred

mineral resources that are considered too speculative geologically to have the

economic considerations applied to them that would enable them to be categorized

as mineral reserves, and there is no certainty that this PEA will be realized.

The inferred mineral resource used in the mine plan is 1.5% of the total LOM

resource.

Three cash flow cases were studied. All cash flow cases used the same mineral

resource estimate and production factors as shown in the table below.

Kutcho PEA - Summary of Production Cases - Main Deposit Only

--------------------------------------------------------------------------

All Cases

Item Unit Totals/Averages

--------------------------------------------------------------------------

Waste mined M tonnes 54.4

--------------------------------------------------------------------------

Mineralized rock mined M tonnes 10.7

--------------------------------------------------------------------------

Strip ratio Waste rock:Plant feed 5.1

--------------------------------------------------------------------------

Mill Feed M tonnes 10.7

--------------------------------------------------------------------------

Copper millhead grade (average) % Cu 1.73%

--------------------------------------------------------------------------

Zinc millhead grade (average) % Zn 2.34%

--------------------------------------------------------------------------

Gold millhead grade (average) g/t Au 0.26

--------------------------------------------------------------------------

Silver millhead grade (average) g/t Ag 26.5

--------------------------------------------------------------------------

Copper in Cu cons M lb 343

--------------------------------------------------------------------------

Zinc in Zn cons M lb 409

--------------------------------------------------------------------------

Gold in Cu cons K oz 46

--------------------------------------------------------------------------

Silver in Cu cons K oz 4,739

--------------------------------------------------------------------------

Cu Concentrate Grade % Cu 30.3%

--------------------------------------------------------------------------

Zn Concentrate Grade % Zn 55%

--------------------------------------------------------------------------

The cash flow cases were differentiated by average metal prices and the results

for each case are shown in the table below. Case 3 pricing was based on the

forward curve for copper as of April, 2008, and spot prices for gold and silver

with no escalation or de-escalation going forward. Case 2 represents an

approximately 15% discount to Case 3 copper gold and silver prices, and Case 1 a

30% discount of copper, gold and silver prices compared to Case 3. Zinc prices

were set at current spot prices for Case 3 with a US$0.01/lb and US$0.02/lb

reduction for Cases 2 and 1 respectively. All cases used a gradual zinc price

decrease to US$0.92/lb by the 4th year of production. Exchange rates are based

on historic correlations of C$ exchange rates and copper prices for Case 3, but

were not changed for case 2 and 1, whereas historic relationships suggest that

the C$ would be weaker than indicated at these metal prices.

Kutcho PEA - Summary of Results by Case - Main Deposit Only

--------------------------------------------------------------------------

Item Unit Case 1 Case 2 Case 3

--------------------------------------------------------------------------

Average Copper Price US$/lb $2.24 $2.73 $3.20

--------------------------------------------------------------------------

Average Zinc Price US$/lb $0.94 $0.95 $0.96

--------------------------------------------------------------------------

Average Gold price US$/oz $600 $725 $850

--------------------------------------------------------------------------

Average Silver price US$/oz $10.00 $13.00 $16.00

--------------------------------------------------------------------------

Exchange rate C$:US$ $1.11 $1.11 $1.11

--------------------------------------------------------------------------

NSR C$/t milled $88 $106 $125

--------------------------------------------------------------------------

Unit Mining costs (ex equip. lease) $/t mined $1.64 $1.64 $1.64

--------------------------------------------------------------------------

Unit Mining costs (ex equip. lease) $/t milled $9.87 $9.87 $9.87

--------------------------------------------------------------------------

Unit Milling costs $/t milled $13.76 $13.76 $13.76

--------------------------------------------------------------------------

Unit G&A and Site services (ex $/t milled $22.13 $22.13 $22.13

equip. lease)

--------------------------------------------------------------------------

Unit Lease costs $/t milled $5.00 $5.00 $5.00

--------------------------------------------------------------------------

Unit Total OPEX (inc royalties) $/t milled $52.49 $52.86 $53.24

--------------------------------------------------------------------------

Unit OPEX C$/lb Cu $1.70 $1.71 $1.72

--------------------------------------------------------------------------

Unit OPEX (with Zn, Au, Ag credits) C$/lb Cu $0.93 $0.87 $0.82

--------------------------------------------------------------------------

Pre-Production Capital (excluding $ M $183.30 $183.30 $183.30

sustaining capital, capital

leases and closure)

--------------------------------------------------------------------------

NPV @ 10% discount rate pre-tax $ M $52 $176 $300

--------------------------------------------------------------------------

NPV @ 10% discount rate after tax $ M $31 $116 $199

--------------------------------------------------------------------------

IRR pre-tax % 19% 38% 54%

--------------------------------------------------------------------------

IRR after tax % 16% 33% 46%

--------------------------------------------------------------------------

Payback period (tax in) Years 3 2 1.5

--------------------------------------------------------------------------

Sensitivity Analysis

Sensitivity analysis was done using metal prices, mill head grade, capital costs

and operating costs as variables. As with many projects, the Net Present Value

("NPV") was most sensitive, in order of magnitude, to metal price, grade and

recovery, operating expenses ("OPEX") and capital expenses ("CAPEX"). Each

variable was changed independently while all other variables were held at the

constant base case level.

In Case 1, a 20% increase in metal prices leads to an increase in the post-tax

NPV using a 10% discount rate ("NPV10%") from $31M to $148M. The mill head grade

and recovery also have a similar large impact with a $79M NPV10% gain for a 20%

increase in grade or recovery. Conversely, decreases in metal prices, mill head

grades or recoveries have a correspondingly large negative effect on the NPV10%.

The Case 1 results show the project is uneconomic if metal prices or mill head

grade/recovery drop by more than 5-7%. Cases 2 assumes higher metal prices than

Case 1 and is therefore more immune to negative metal price changes. Case 2

shows the same large variances in NPV10% as Case 1 but an 18% drop in metal

prices is required before it will lead to a negative NPV10%. Case 3 assumes

metal prices approximately in line with the forward curve for copper and zinc,

but with no escalation of precious metal prices, and is the most robust

scenario.

Environmental

The Kutcho Project is subject to the British Columbia Environmental Assessment

Act and the Canadian Environmental Assessment Act. The former requires that the

project undergo an environmental assessment and obtain an Environmental

Assessment ("EA") Certificate. The Project was initiated into the BC EA process

through the issuance of a Section 10 order by the BC Environmental Assessment

Office ("EAO") on July 29, 2005. The provincial and federal processes will be

integrated in a harmonized review, with the EAO taking the lead. On December 24,

2007, the Canadian Environmental Assessment Agency announced that the Kutcho

Project would be subject to a Comprehensive Study.

In 2005, a program of environmental and socio-economic baseline studies was

begun to provide the information necessary to prepare the EA Application and to

develop management and monitoring plans. It covered all facets of the

biophysical and human environment, including meteorology, air quality,

hydrology, hydrogeology, metal leaching and acid rock drainage, aquatic ecology,

fish and fish habitat, soils, vegetation, ecosystem mapping, wildlife, wetlands,

archaeology, socio-economics, land use, country foods and human health, and

traditional use and traditional ecological knowledge. The program was completed

in 2007. Monitoring of meteorology, air quality, hydrology and water quality

will continue throughout the construction, operation, closure and post-closure

phases. The most significant environmental issue for the Project will be

maintaining water quality in the receiving environment. Treatment of mine

effluent to BC water quality criteria will be required during all mine phases.

The Kutcho Project is in the traditional territories of the Tahltan and Kaska

Dena First Nations. Consultation with these First Nations and other stakeholders

has been ongoing since activity at the Kutcho Project re-started approximately

four years ago.

Project Risks

The major risk areas identified in the PEA are:

1. Environmental and permitting requirements could delay or preclude the

development of the Kutcho Project;

2. Adverse changes in exchange rates, metal prices and external financial

influences could negatively impact the development of the project;

3. Process recoveries could be less than assumed in the PEA, negatively

affecting project returns;

4. Potential for increases in capital costs over those estimated in the PEA;

5. Poor grade control could result in over-dilution of the high grade

mineralization, negatively affecting recoveries.

Project Opportunities

The most important opportunities to improve the project are:

1. Increased grade of the in situ mineral resource as a result of in-fill

drilling currently in process (In-fill drilling in 2006 on a limited portion of

the Main deposit suggested potential to increase overall mineral resource grades

versus that previously modelled - with a comprehensive in-fill drill program

underway, Sherwood will be better able to evaluate this opportunity by the fall

of 2008);

2. Optimization of mine plan following in-fill drilling to maximize grade and

reducing stripping in the early years of the mine plan (an increase of 1M tonnes

of mill feed at the average grade used in the PEA would increase the pre-tax

NPV10% $12M;

3. Increased life of mine production as a result of mining additional mineral

resources from the Main pit (only 63% of the Main deposit mineral resource is

extracted in the proposed open pit, leaving 6.3Mt that could be exploitable,

depending on metal prices and costs, and extending the mine life);

4. Exploitation of mineral resources from the other deposits already known (Esso

and Sumac) which, together with the unmined portion of the Main deposit,

comprise more than 50% of the total project resources;

5. Reduced stripping by steepening pit walls, if supported by planned

geotechnical drilling (a 0.1 reduction in the strip ratio increases the pre-tax

NPV10% by $1M);

6. Improved metallurgical recoveries in the process plant as a result of

metallurgical test work currently in process (a 1% increase in recoveries

increases the pre-tax NPV by $7M and IRR by 1%) and improved concentrate grades

(a 1% increase in concentrate grade increases pre-tax NPV10% by $4M);

7. Reduced energy usage as equipment is specified and sized;

8. Reduced capital costs through expanded utilization of used and refurbished

equipment;

9. Reduced overall transportation costs of concentrate from mine to smelter (a

10% reduction increases pre-tax NPV10% by $3M); and

10. Potential for lower than assumed TC/RC's, especially copper, where current

rates are well below those assumed in the PEA (a10% reduction in TC/RC's

increases pre-tax NPV10% by $3M).

It should be noted that the upside potential indicated above could also become

negative if the factors are worse than expected. In this regard, the list can be

used to identify which parameters might have the largest positive or negative

effect on the project and risk mitigation plans could be developed.

Moving Forward

As a result of the recommendations in the PEA, Sherwood has an extensive work

program underway to investigate the project opportunities identified and to

mitigate the project risks. This work program includes:

1. In-fill drilling the Main deposit in order to better define the high grade

mineralization, optimize the mine planning and enhance the quality of the assay

database;

2. Geotechnical investigations to steepen up the pit walls and reduce the

overall stripping;

3. Evaluating the potential of an expanded open pit or underground extraction of

the unplanned portions of the Main deposit immediately adjacent to the current

proposed open pit;

4. Evaluating the potential of the Esso and Sumac resources as potential sources

of supplemental feed, possibly by ramp access out of the proposed open pit,

extending the mine life;

5. Extensive metallurgical testing in order to determine the potential for

improved metallurgical recoveries and improved concentrate grades;

6. Possible recovery of free gold in a gravity circuit;

7. Conducting more ABA testing to better define the extent of potentially acid

generating rock;

8. Geotechnical and hydrogeological evaluations to optimize open pit planning;

9. Re-engage the regulatory agencies to advance the Kutcho copper project

through the permitting process.

10. Re-engage the Tahltan and Kaska First Nations to attain meaningful and

equitable IBA agreements.

An updated PEA is planned for the fall of 2008, incorporating some or all of the

results from items #1, #3, #4 and #5 above, and a feasibility study in the first

half of 2009 (depending on timeliness of work programs required to support a

feasibility study).

Resource Estimation Methodology

Kirkham Geosystems Ltd. prepared the mineral resource estimate for the Kutcho

deposit. Mr. Kirkham has reviewed pertinent geological information in sufficient

detail to support the data incorporated in the resource estimate. Garth Kirkham,

P.Geo. of Kirkham Geosystems Ltd. is the Independent Qualified Person under

National Instrument 43-101 responsible for the resource estimate.

The estimates for copper, zinc, silver and gold were completed for the PEA

Report dated June of 2008 using the MineSight(TM) 3-dimensional mine planning

software system. The estimate was based upon a database comprised of 346 drill

holes supplied by Kutcho Copper. The estimation process was constrained by a

solid model based on lithological boundaries combined with grade contours.

Assays were then composited into 2.5m intervals for statistical and

geostatistical analysis to be performed within the constraining domains. A 5m by

5m by 5m orthogonal block model was created and Ordinary Kriging was used as the

method to interpolate grades into each block within the solid domain. Bulk

density measurements were supplied within the drill hole database and also

interpolated into each block using Inverse Distance to the 3rd power as the

interpolator. Individual blocks were then classified into indicated and inferred

categories based on number of drillholes, number of composites, average distance

to composite, distance to nearest composite and relative error. The grades and

tonnages reported in the resource estimate represent the material contained

within the mineralized portion (as a percentage) of the classified block below

topography.

Mineral resources that are not mineral reserves do not have demonstrated

economic viability. Mineral resource estimates do not account for mineability,

selectivity, mining loss and dilution. These mineral resource estimates include

inferred mineral resources that are normally considered too speculative

geologically to have economic considerations applied to them that would enable

them to be categorized as mineral reserves. There is also no certainty that

these inferred mineral resources will be converted to measured and indicated

mineral resource categories through further drilling, or into mineral reserves

once economic considerations are applied.

Technical Report

A National Instrument 43-101 compliant technical report will be filed within the

next week on SEDAR and, once filed, can be accessed under Sherwood's profile at

www.sedar.com.

Diagrams

Kutcho PEA - Claim area showing schematic of proposed mine site -

http://media3.marketwire.com/docs/swc612a.pdf

Kutcho PEA - Proposed project layout - http://media3.marketwire.com/docs/swc612b.pdf

Kutcho PEA - Computer Generated Image of the Three Known Massive Sulphide

Deposits, Drill Holes, and Surface Topography (Wardrop 2007) -

http://media3.marketwire.com/docs/swc612c.pdf

Kutcho PEA - Proposed phasing of open pit on Main deposit (looking south) -

http://media3.marketwire.com/docs/swc612d.pdf

About Sherwood Copper

Sherwood's objective is the profitable production of base and precious metals

from high grade, open pit mines in Canada. Sherwood's first operating mine, the

high grade Minto copper-gold mine in Yukon, Canada, was built on budget and

ahead of schedule. The Minto Mine is one of the highest-grade open pit

copper-gold mines in the world, and is forecast to be a low cost producer.

Aggressive exploration on the Minto property has yielded significant success,

providing Sherwood the opportunity to 'grow from within' by expanding the

mineral resource and mineral reserve base, potentially leading to further

production increases. To further accelerate its production growth, Sherwood

intends to pursue merger & acquisition opportunities that fit its business model

and, in May 2008, Sherwood acquired 100% ownership in Western Keltic Mines Ltd.,

owner of the high-grade Kutcho copper-zinc-gold-silver deposit in northwestern

British Columbia. Sherwood expects to lever off its successful development of

the Minto Mine and rapidly advance the Kutcho Project to a production decision.

Quality Assurance

The technical information in this news release has been prepared in accordance

with Canadian regulatory requirements set out in National Instrument 43-101 and

reviewed by Stephen P. Quin, P.Geo., President & CEO of Sherwood. The following

SRK employees are QPs for this project; Gordon Doerksen, P.E. (WY) - Project

Overview; Dino Pilotto, P.Eng. - Mining;. Garth Kirkham, P.Geo. of Kirkham

Geosystems - Mineral Resource Estimates, Jeff Stibbard P.Eng. - Capital, G&A and

Operating Costs, Dave Hendriks, P.Eng. - Metallurgy and Mineral Processing, Brad

Mercer P.Geo. - Geology.

The report relies on the work and opinions of non-QP experts without

verification by SRK, including: Roger Nonis and Robert Johnston, P.Eng., of

Sacre-Davey Engineering (mineral processing and project infrastructure), Mike

McGurk of Rescan Environmental (environmental and permitting), Carl Hovey of

All-North Consultants (access road and site earthworks), Wentworth Taylor of WH

Taylor Inc. (taxation).

Additional Information

Additional information on Sherwood and its Minto & Kutcho projects can be

obtained on Sherwood's website at http://www.sherwoodcopper.com.

On behalf of the board of directors

SHERWOOD COPPER CORPORATION

Stephen P. Quin, President & CEO

Forward-Looking Statements

This document may contain "forward-looking statements" within the meaning of

Canadian securities legislation and the United States Private Securities

Litigation Reform Act of 1995. These forward-looking statements are made as of

the date of this document and the Company does not intend, and does not assume

any obligation, to update these forward-looking statements.

Forward-looking statements relate to future events or future performance and

reflect management's expectations or beliefs regarding future events and

include, but are not limited to, statements with respect to the estimation of

mineral reserves and resources, the realization of mineral reserve estimates,

the timing and amount of estimated future production, costs of production,

capital expenditures, success of mining operations, environmental risks,

unanticipated reclamation expenses, title disputes or claims and limitations on

insurance coverage. In certain cases, forward-looking statements can be

identified by the use of words such as "plans", "expects" or "does not expect",

"is expected", "budget", "scheduled", "estimates", "forecasts", "intends",

"anticipates" or "does not anticipate", or "believes", or variations of such

words and phrases or statements that certain actions, events or results "may",

"could", "would", "might" or "will be taken", "occur" or "be achieved" or the

negative of these terms or comparable terminology. By their very nature

forward-looking statements involve known and unknown risks, uncertainties and

other factors which may cause the actual results, performance or achievements of

the Company to be materially different from any future results, performance or

achievements expressed or implied by the forward-looking statements. Such

factors include, among others, risks related to actual results of current

exploration activities; changes in project parameters as plans continue to be

refined; future prices of resources; possible variations in ore reserves, grade

or recovery rates; accidents, labour disputes and other risks of the mining

industry; delays in obtaining governmental approvals or financing or in the

completion of development or construction activities; as well as those factors

detailed form time to time in the Company's interim and annual financial

statements and management's discussion and analysis of those statements, all of

which are filed and available for review on SEDAR at www.sedar.com. Although the

Company has attempted to identify important factors that could cause actual

actions, events or results to differ materially from those described in

forward-looking statements, there may be other factors that cause actions,

events or results not to be as anticipated, estimated or intended. There can be

no assurance that forward-looking statements will prove to be accurate, as

actual results and future events could differ materially from those anticipated

in such statements.

Accordingly, readers should not place undue reliance on forward-looking statements.

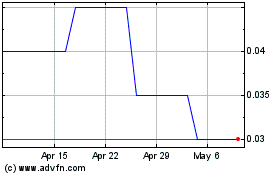

Kincora Copper (TSXV:KCC)

Historical Stock Chart

From Jun 2024 to Jul 2024

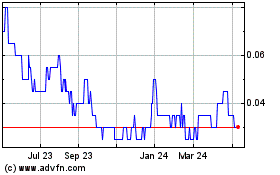

Kincora Copper (TSXV:KCC)

Historical Stock Chart

From Jul 2023 to Jul 2024