UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

___________________

FORM SD

Specialized Disclosure Report

___________________

Park-Ohio Holdings Corp.

(Exact name of registrant as specified in its charter)

| | | | | | | | | | | | | | |

|

| | | | |

| | | | | |

Ohio | | 000-031341 | | 34-1867219 |

(State or other jurisdiction | | (Commission | | (IRS Employer |

of incorporation or organization) | | File Number) | | Identification No.) |

| |

6065 Parkland Blvd. |

|

Cleveland, Ohio 44124 |

(Address of principal executive offices, including zip code) |

| | |

|

|

| |

| |

(Name and telephone number, including area code, of the person to contact in connection with this report.) |

Check the appropriate box to indicate the rule pursuant to which this form is being filed, and provide the period to which the information in this form applies:

| | | | | |

|

| |

| x | Rule 13p-1 under the Securities Exchange Act (17 CFR 240.13p-1) for the reporting period from January 1 to December 31, 2023. |

Section 1 – Conflict Minerals Disclosure

Item 1.01 Conflict Minerals Disclosure and Report

Conflict Minerals Disclosure

This Form SD of Park-Ohio Holdings Corp. (the “Company”) is filed pursuant to Rule 13p-1 under the Securities Exchange Act of 1934, as amended, for the reporting period from January 1, 2023 through December 31, 2023.

A copy of the Company’s Conflict Minerals Report is filed as Exhibit 1.02 to this Form SD, and is in the investor relations section/SEC filings of the Company’s website at http://www.pkoh.com.

Item 1.02 Exhibit

A copy of the Company’s Conflict Minerals Report is filed as Exhibit 1.02 hereto.

Section 2 – Exhibits

Item 2.01 Exhibits

The following exhibit is filed as part of this Form SD.

| | | | | | | | |

|

| | |

Exhibit

Number | | Description of Exhibit |

| | | |

1.02 | | |

SIGNATURES

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the duly authorized undersigned.

| | |

|

|

| Park-Ohio Holdings Corp. |

| (Registrant) |

| | |

|

|

| /s/ Robert D. Vilsack |

| Robert Vilsack |

| General Counsel & Secretary |

EXHIBIT INDEX

| | | | | | | | |

|

| | |

Exhibit

Number | | Description of Exhibit |

| | | |

1.02 | | |

Exhibit 1.02

Park-Ohio Holdings Corp.

Conflict Minerals Report

For the reporting period from January 1, 2023 to December 31, 2023

Introduction

This Conflict Minerals Report (“Report”) for the Company has been prepared pursuant to Rule 13p-1 and Form SD promulgated under the Securities Exchange Act of 1934, as amended (the “Rules”), for the reporting period from January 1, 2023 through December 31, 2023 (the “Reporting Period”).

The Rules require disclosure of certain information when a company manufactures or contracts to manufacture products and the minerals specified in the Rules are necessary to the functionality or production of those products. The minerals covered by the Rules are gold, columbite-tantalite (coltan), cassiterite, and wolframite, including their derivatives consisting of tin, tungsten, and tantalum (collectively, “Conflict Minerals”) and the countries by this Report are the Democratic Republic of the Congo or any adjoining country (collectively, “Covered Countries”).

In this Report, unless the context otherwise indicates, “the Company”, “we”, “us” and “our” mean Park-Ohio Holdings Corp. and its consolidated subsidiaries.

Our operations may at times manufacture, or contract to manufacture, products for which Conflict Minerals are necessary to the functionality or production of those products. The Company does not directly purchase these minerals from smelters or mines and works closely with our suppliers to ensure responsible sourcing of Conflict Minerals necessary to the production or functionality of its products. The Company supports the objectives of the legislation and sources materials from companies that share our values around human rights, ethics and responsibility. We expect our suppliers to comply with our Code of Business Conduct and meet the objectives of our conflict minerals policy. Our Conflict Minerals Policy, Form SD and this Report are publicly available on our website at www.pkoh.com.

This Report is not audited, nor is an independent private sector audit required for this Report under the Rules and SEC guidance.

The Company and Our Products

The Company operates through three reportable segments: Supply Technologies, Assembly Components and Engineered Products.

Supply Technologies provides our customers with Total Supply Management ™ services for a broad range of high-volume, specialty production components. Total Supply Management ™ manages the efficiencies of every aspect of supplying production parts and materials to our customers’ manufacturing floor, from strategic planning to program implementation, and includes such services as engineering and design support, part usage and cost analysis, supplier selection, quality assurance, bar coding, product packaging and tracking, just-in-time and point-of-use delivery, electronic billing services and ongoing technical support. The principal customers of Supply Technologies are in the heavy-duty truck; automotive, truck and vehicle parts; power sports and recreational equipment; bus and coaches; electrical distribution and controls; agricultural and construction equipment; consumer electronics; HVAC; lawn and garden; semiconductor equipment; aerospace and defense; and plumbing.

Assembly Components manufactures cast and machined aluminum components, automotive and industrial rubber and thermoplastic products, fuel filler and hydraulic assemblies for automotive, agricultural equipment, construction equipment, heavy-duty truck and marine equipment industries. Assembly Components also provides value-added services such as design and engineering, machining and assembly.

Engineered Products operates a diverse group of niche manufacturing businesses that design and manufacture a broad range of high quality products engineered for specific customer applications. The principal customers of Engineered Products are original equipment manufacturers (“OEMs”) and end users in the ferrous and non-ferrous metals, silicon, coatings, forging, foundry, heavy-duty truck, construction equipment, automotive, oil and gas, rail and locomotive manufacturing and aerospace and defense industries.

The magnitude of our products and services along with our widespread supply chain networks, create a monumental task for all business units to evaluate the presence of Conflict Minerals in their products and track the sources of these

applicable Conflict Minerals. We conduct analyses of our products to determine which of our products are likely to contain Conflict Minerals and, as a result, identified products that are the focus of our good faith reasonable country of origin inquiry (“RCOI”).

As a contract manufacturer, we produce our products to the design and specifications of our customers. Our customers frequently specify the exact materials and components we use, and in many cases specify the suppliers from which we source these materials and components. As a result, we are limited in our ability to exercise discretion in sourcing certain materials and components. Similarly, our ability to influence the supply chain practices of suppliers selected by our customers, including their cooperation with our good faith RCOI and related due diligence, is limited. Therefore, our ability to change the sourcing of our Conflict Minerals depends on our customers’ selection of suppliers and designs.

Reasonable Country of Origin Inquiry

The Company has conducted a good faith Reasonable Country of Origin Inquiry (RCOI) that was designed to determine whether any of the necessary conflict minerals contained in our products originated or may have originated in a Covered Country or come from recycled or scrap sources. “Necessary Conflict Minerals” are Conflict Minerals that are necessary to the functionality or production of products that we manufacture or that we contract to manufacture.

The Company’s supply chain is complex, and there are many indirect suppliers in the supply chain between us and the mines or locations of origin of our Necessary Conflict Minerals. Therefore, we must rely on our direct and indirect suppliers to provide information about the origin of the Necessary Conflict Minerals in our products, including where possible, the smelters of the Conflict Minerals. Similarly, our suppliers may depend on their direct suppliers for this information.

To conduct our RCOI, we identified our suppliers that we believed were potentially providing materials and components that contained Necessary Conflict Minerals. In our supplier engagement, we provided information to our suppliers about the specifics of the SEC’s conflict minerals rule and explained our inquiries. We requested information from our suppliers about the presence and sourcing of Conflict Minerals used in the materials and components supplied to us during the reporting period. We requested these suppliers to provide their responses using the most recent specialized Conflict Mineral Report Template (“CMRT”) indicating the facility at which the Conflict Minerals were processed.

We followed up with suppliers who did not respond to our requests and also with those whose answers were incomplete or unreliable.

Due Diligence Process

In addition to our RCOI, we conducted additional due diligence measures to conform, in all materials respects, with the due diligence framework set forth in The Organization for Economic Co-operation and Development Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas, including the related supplements for gold, tin, tantalum, and tungsten (OECD Guidance). We performed the following due diligence measures:

| | | | | |

| |

• | Step 1 - Establish strong company management systems: |

The Company required each business unit to assemble a team responsible for evaluating their products for the presence of Conflict Minerals and to establish policies for internal reporting of Conflict Minerals. These teams consisted of various individuals who were familiar with the respective product lines and supplier base. These cross functional teams included purchasing managers, engineers, metallurgists, and others to gather the information from their suppliers regarding the source of Conflict Minerals contained in our products. These teams managed the distribution and collection of CMRTs and oversaw changes in the reported data.

The Company’s business units have made efforts to incorporate Conflict Minerals language within their contracts and/or agreements with suppliers which is clearly communicated through various mechanisms.

| | | | | |

| |

• | Step 2 - Identify and assess risks in the supply chain: |

We have worked on our system in order to increase our supply chain transparency and identify risks within our supply chain. Our continued efforts will evaluate responses from our suppliers to understand inconsistencies in which materials were reported to contain or not contain Conflict Minerals as well as the origin of those Conflict Minerals.

Because of our size, the complexity of our products, and the depth, breadth, and constant evolution of our supply chain, it is difficult to identify actors upstream from our direct suppliers. We therefore have to rely on the responses from our suppliers and their ability to push the information requests on to their suppliers in order to obtain the required information on Conflict Minerals sourcing. We engage certain suppliers in periodic quality assessments which assist us in understanding these suppliers compliance to our Conflict Minerals Policy.

| | | | | |

| |

• | Step 3 - Design and implement a strategy to respond to identified risks: |

We continue to develop and execute processes to, i) identify suppliers that potentially provide materials and components that contain Conflict Minerals and, ii) conduct good faith RCOI of our supply chain, including a risk-based evaluation of our suppliers’ responses.

| | | | | |

| |

• | Step 4 - Carry out independent third-party audit of smelter/refiner due diligence : |

We do not have a direct relationship with smelters and refiners of Conflict Minerals and do not perform direct audits of these entities within our supply chain. We support voluntary independent third-party audits for smelters and refiners under the Conflict-Free Smelter Program (CFSP).

| | | | | |

| |

• | Step 5 - Report annually on supply chain due diligence : |

|

|

In addition to our ongoing communications with our customers who are engaged in their own due diligence processes, we report annually to the SEC utilizing Form SD. Our reports are publicly available at www.pkoh.com.

Results of Review

Based on the results of our RCOI and Due Diligence Process described above, we do not have sufficient information to determine the country of origin of all the Conflict Minerals we use to manufacture and/or contract to manufacture our products, and thus are unable to determine whether any of the Conflict Minerals originated in Covered Countries.

Despite our efforts to follow up with certain suppliers, we did not receive responses from all suppliers, and those who responded showed varying degrees of cooperation with our inquiries. In addition, we encountered the following challenges in obtaining and analyzing the responses we received:

| | | | | |

| |

• | We are dependent on information received from our direct suppliers to conduct our good faith RCOI process; |

| | | | | |

| |

• | Many suppliers provided responses at a company or divisional level, and not at a product level specific to the materials and components we use in our products; |

| | | | | |

| |

• | We have a varied supplier base with differing levels of resources and sophistication, and many of our suppliers are not themselves subject to the Rules; |

| | | | | |

| |

• | Certain suppliers were unable or unwilling to specify the smelters or refiners used for materials and components supplied to us and the information our suppliers provided was often incomplete and required significant follow-up; and |

| | | | | |

| |

• | Our ability to influence cooperation from certain suppliers was limited when our use of these suppliers was mandated by our customers or when we were multiple tiers away from the supplier in the supply chain. As a result, we have not been able to identify all of the smelters from which our suppliers sourced the Conflict Minerals. |

Steps to Mitigate Risk

To address our ongoing obligations in 2024 under the Rules and our Conflict Minerals Policy, we intend to improve our RCOI and due diligence process. To further mitigate any risk that the Necessary Conflict Minerals in our products could benefit conflict in the Covered Countries, we expect to implement the following steps:

| | | | | |

| |

• | Continue to request assistance from our customers to good faith RCOI when some customers require us to source materials and components from specific suppliers; |

| | | | | |

| |

• | Periodically survey our supply chain and follow-up when questionnaires warrant further investigation; |

| | | | | |

| |

• | Encourage the applicable supply chain vendors to provide us the names of smelters and refiners that process the Necessary Conflict Minerals used in our products and to continue to encourage these vendors to obtain detailed information from their suppliers; and |

| | | | | |

| |

• | Continue to work with and to partner with trade organizations, and encourage our vendors/suppliers to implement reasonable sourcing of smelters who have been designated as “conflict free” through independent smelter validation programs. |

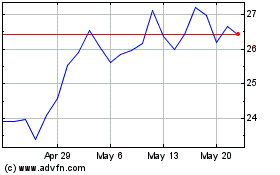

Park Ohio (NASDAQ:PKOH)

Historical Stock Chart

From May 2024 to Jun 2024

Park Ohio (NASDAQ:PKOH)

Historical Stock Chart

From Jun 2023 to Jun 2024