- Important milestone towards “Ambition 2039”: Swedish

start-up H2 Green Steel (H2GS) to supply approx. 50,000 tonnes of

almost CO₂-free steel per year, to be launched in various

Mercedes-Benz vehicle models

- “Local for local” approach: Mercedes-Benz and H2GS

further agreed on extending their partnership with a joint ambition

to establish a sustainable steel supply chain in North America

- Sustainable steel supply chain: Mercedes-Benz plans to

decarbonize its steel supply chain with various partners

worldwide

Mercedes-Benz signed a supply agreement with Swedish start-up H2

Green Steel (H2GS) over approximately 50,000 tonnes almost CO₂-free

steel per year for its European press shops and deepened its

partnership through a Memorandum of Understanding (MoU) with the

aim to establish a sustainable steel supply chain in North

America.

After taking an equity stake in H2GS in 2021, the new supply

agreement enables Mercedes-Benz to bring almost CO₂-free steel into

series production. The partner plans to start its production during

2025.

As part of a broader effort to decarbonize the supply chain,

Mercedes-Benz and H2GS agreed to aim to establish a supply chain

for green steel produced in North America for local Mercedes-Benz

manufacturing plants. Extending the strategic partnership with H2GS

to North America marks another important milestone in increasingly

pursuing the strategy of procuring close to Mercedes-Benz

production sites.

“With the supply deal of around 50,000 tonnes

almost CO₂-free steel from H2 Green Steel for our manufacturing

plants in Europe, Mercedes-Benz and H2 Green Steel are accelerating

the creation of a decarbonized, regional and resilient steel supply

chain. At the same time, we are taking our partnership to the next

level with the aim of establishing a sustainable steel supply chain

in North America, another important step towards making the auto

industry more resilient and sustainable.”

Markus Schäfer, Member of the Board of

Management of Mercedes-Benz Group AG. Chief Technology Officer,

Development & Procurement

“Together with our strategic partner H2 Green

Steel we’ve achieved the next milestone of our local for local

strategy in procurement. Based on our initial investment into H2

Green Steel we now have a finalized relevant supply agreement for

Europe and are looking at establishing a sustainable steel supply

with H2 Green Steel in North America.”

Dr. Gunnar Güthenke, Head of Procurement and

Supplier Quality, Mercedes-Benz Cars

Almost CO₂ free manufacturing technology

By using a new, innovative manufacturing process, the production

of steel at the H2GS production site is almost CO₂-free. By

contrast, steel produced using a classic blast furnace, emits an

average of more than two tons of CO₂ per ton. In the new process,

the supplier uses hydrogen and electricity from 100% renewable

energy sources instead of coking coal in steel production. The

hydrogen serves as a reduction gas, which releases and binds the

oxygen from the iron ore. Unlike the use of coking coal, this does

not produce CO₂, but water vapor. H2GS aims to achieve a footprint

of 0.4t CO₂ per ton of steel at start of supply.

“H2 Green Steel exists because pioneering

companies in the automotive industry, like Mercedes-Benz, signaled

the transition in the steel industry was too slow for them to meet

their climate targets. Working side-by-side with Mercedes Benz, we

have a partner with whom we can raise the bar when it comes to

supply chain emissions, circularity and social sustainability. They

are a very strong player to liaise with for our European

operations, but naturally also as we endeavor into the steel value

chain in North America.”

Henrik Henriksson, CEO, H2 Green Steel

Decarbonizing the supply chain

Mercedes-Benz is working with all its suppliers towards a

net-carbon neutral supply chain from 2039 at the latest. To achieve

its ambitious climate goals the luxury carmaker is retooling its

supply chain to focus on the prevention and reduction of CO₂

emissions rather than off-setting. Already today, the brand with

the three-pointed star has introduced low-CO₂ steel, made from

scrap, into four series models. This allows CO₂ emissions for the

respective steel grades to be cut by more than 60%. Moreover,

Mercedes-Benz recently announced to bring aluminium with almost 70%

CO₂-reduction compared with the European average into series

production as the lightweight material is becoming increasingly

important for electric vehicles. At the same time, Mercedes-Benz

aims to increase the share of secondary raw materials in its

passenger car fleet to an average of 40%. Mercedes-Benz and H2GS

agreed to collaborate on levers to increase the scrap content

accordingly.

Actively pursuing a responsible and sustainable supply

chain

In addition to consequently reducing CO₂ emissions, the company

is committed to a responsible steel supply, relying on the

application of recognized standards and robust certificates.

Mercedes-Benz and H2GS share the same understanding of

sustainability and intend to establish highest standards in terms

of human rights due diligence along the steel supply chain.

Mercedes-Benz is a member of the Responsible Steel Initiative and

is actively involved in the development of a certifiable

sustainability standard for the steel industry. The aim is to

ensure environmentally compatible and socially acceptable steel

production along the entire value chain.

About Mercedes-Benz

Mercedes-Benz has set itself the target of making its fleet of

new vehicles net carbon-neutral over the vehicles’ entire life

cycle by 2039. When it comes to sustainability, the company is

focused on the consistent reduction of CO₂ emissions as well as the

preservation of resources. In 2020, Mercedes-Benz Cars and

Mercedes-Benz Vans sent out an ambition letter to suppliers of

production materials. This was a declaration of intent on the

supply of net carbon-neutral products and established prior

approval as a prerequisite for awarding contracts. Suppliers

representing almost 90% of Mercedes-Benz's annual purchasing volume

have already signed the letter, among them many steel

suppliers.

The vehicle manufacturer’s “Design for Environment” approach

takes resource preservation from the very earliest stages of

product development into account. Together with its partners,

Mercedes-Benz is researching more sustainable material technologies

and working intensively towards circularity.

About H2 Green Steel

H2 Green Steel (H2GS AB) was founded in 2020 with the ambition

to accelerate the decarbonization of the steel industry, using

green hydrogen. Steel, which is one of the world’s largest carbon

dioxide emitters, is the company’s first business vertical. The

founder and largest shareholder of H2 Green Steel is Vargas, which

is also co-founder and one of the larger shareholders in Swedish

battery maker Northvolt. H2 Green Steel is headquartered in

Stockholm, Sweden, with its first green steel plant under

development in Boden, northern Sweden. www.h2greensteel.com

Further information about Mercedes-Benz is available at

www.mercedes-benz.com. Press information and digital services for

journalists and multipliers can be found on our Mercedes me media

online platform at media.mercedes-benz.com as well as on our

Mercedes-Benz media site at group-media.mercedes-benz.com. Learn

more about current topics and events related to Mercedes-Benz Cars

& Vans on our @MB_Press Twitter channel at

www.twitter.com/MB_Press.

Mercedes-Benz AG at a glance

Mercedes-Benz AG is part of the Mercedes-Benz Group AG with a

total of around 170,000 employees worldwide and is responsible for

the global business of Mercedes-Benz Cars and Mercedes-Benz Vans.

Ola Källenius is Chairman of the Board of Management of

Mercedes-Benz AG. The company focuses on the development,

production and sales of passenger cars, vans and vehicle-related

services. Furthermore, the company aspires to be the leader in the

fields of electric mobility and vehicle software. The product

portfolio comprises the Mercedes-Benz brand with the brands of

MercedesAMG, MercedesMaybach, MercedesEQ, GClass as well as

products of the smart brand. The Mercedes me brand offers access to

the digital services from Mercedes-Benz. Mercedes-Benz AG is one of

the world's largest manufacturers of luxury passenger cars. In 2022

it sold around two million passenger cars and 415,300 vans. In its

two business segments, Mercedes-Benz AG is continually expanding

its worldwide production network with around 35 production sites on

four continents, while gearing itself to meet the requirements of

electric mobility. At the same time, the company is constructing

and extending its global battery production network on three

continents. As sustainability is the guiding principle of the

Mercedes-Benz strategy and for the company itself, this means

creating lasting value for all stakeholders: for customers,

employees, investors, business partners and society as a whole. The

basis for this is the sustainable business strategy of the

Mercedes-Benz Group. The company thus takes responsibility for the

economic, ecological and social effects of its business activities

and looks at the entire value chain.

View source

version on businesswire.com: https://www.businesswire.com/news/home/20230607005531/en/

Pia Droldner, phone: +49 (0) 176 30988043,

pia.droldner@mercedes-benz.com Aline Meiser, phone: +49 (0) 176

30900064, aline.meiser@mercedes-benz.com Andrea Berg, phone: +01

(0) 917 6672391, andrea.a.berg@mercedes-benz.com

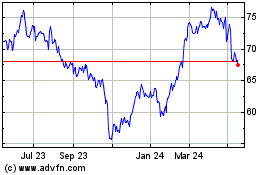

MercedesBenz (TG:MBG)

Historical Stock Chart

From Dec 2024 to Jan 2025

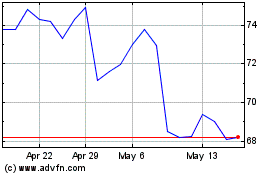

MercedesBenz (TG:MBG)

Historical Stock Chart

From Jan 2024 to Jan 2025