Doré Copper Mining Corp. (the "

Company" or

"

Doré Copper") (TSXV: DCMC; OTCQX: DRCMF; FRA:

DCM) is pleased to announce positive results from ore sorting test

work for its flagship Corner Bay high-grade copper-gold project

located approximately 55 kilometers by road from the Corporation’s

Copper Rand mill, near Chibougamau, Québec.

Steinert was commissioned to complete ore

sorting tests at their facility in Kentucky, United States, using a

XRT sensor (X-ray transmission) and a laser sensor on a spatially

diverse sample from the Corner Bay deposit.

The results support the first ore sorting test

work that was completed for the preliminary economic assessment

(“PEA”) and further confirm the effectiveness of utilizing ore

sorting technology to improve the processed grade and reduce the

mill feed tonnage.

Highlights of Ore Sorting

Test

- Copper grade increase

of 77%, from 2.20% to 3.93%

- Recovery of 93.6%

Cu

- Reject material contains 48% of the

initial mass with a copper grade of 0.30%

- Gold, silver and molybdenum grade

also upgraded with excellent recoveries and low concentration in

reject

- Cost and environmental benefits

include:

- Lower transportation costs and

greenhouse gas emissions (GHGs) due to a reduction of transported

material from the mine to the mill

- Lower energy consumption at the

mill due to higher feed grade and hardness decrease of the feed

material

- Less tailings produced

- Additional capacity of the mill to

treat additional materials

- Waste material at the mine site

(reject material) to be used as backfill

Commenting on the results of our second ore

sorting tests, Ernest Mast, President & CEO, stated, "This

test work further validates the favorable mineralogy of the Corner

Bay deposit for ore sorting technology and confirms the prior ore

sorting results obtained from the Corner Bay stockpile, which were

included in the PEA. Preliminary ore sorting test work at Devlin in

2022, our secondary hub-and-spoke asset, had also indicated

positive results. Ore sorting of the Corner Bay and Devlin will

remain part of any future development scenarios due to its economic

and sustainability benefits."

Ore Sorting Tests

As a first step, the Steinert XRT was calibrated

with high, medium and low grade and waste samples representative of

the selected drill core samples of the Corner Bay deposit (Figure

1). A continuous production run was done on the 202 kg sample. The

testing was done with three passes with the explicit aim of

generating grade vs recovery vs mass pull curves, with each pass

related to an adjustment in the sensitivity. Results are shown in

the table below.

The sum of the two pre-concentrates (Test 2 in

table below) represented 52.5% of the feed mass at a grade of 3.93%

Cu (an increase of 77%) and resulted in a cumulative copper

recovery of 93.6%. The final reject portion represented 47.5% of

the feed mass at a grade of 0.30% Cu, representing 6.4% of the

copper fed in the sorter. In addition, all other metals to be

recovered (gold, silver and molybdenum) showed an upgrade in

grade:

- Gold grade: from 0.17 g/t to 0.29

g/t

- Silver grade: from 7.91 g/t to

13.82 g/t

- Molybdenum grade: from 0.037% to

0.064%

Lastly, the arsenic grade of the two

pre-concentrates was found to be 12ppm which leads to a final

concentrate with very low levels of arsenic.

Minimal fines were generated in the test work

and were not considered for calculations. In practice, the fine

material from the mining and crushing would join the

pre-concentrate in the ore sorting circuit and would result in a

higher recovery than indicated in the test work. In addition, as

the sorter can be calibrated to control the final reject grade, a

higher copper feed grade would result in higher recoveries.

|

Corner Bay Ore Sorting Results Cumulative

Results |

|

Result(cumulative) |

Weight (kg) |

Mass Recovery |

Cu (%) |

CuRec. |

Au (g/t) |

AuRec. |

Ag(g/t) |

AgRec. |

Mo(%) |

MoRec. |

|

1 |

70 |

34.7% |

5.18 |

81.4% |

0.37 |

77.2% |

17.90 |

78.4% |

0.082 |

77.2% |

|

2 |

106 |

52.5% |

3.93 |

93.5% |

0.29 |

92.2% |

13.82 |

91.7% |

0.064 |

91.7% |

|

3 |

175 |

86.6% |

2.52 |

99.0% |

0.19 |

98.4% |

9.00 |

98.6% |

0.042 |

98.2% |

|

4 |

202 |

100.0% |

2.20 |

100.0% |

0.17 |

100.0% |

7.91 |

100.0% |

0.037 |

100.0% |

Corner Bay Composite Sample

A spatially diverse composite sample was

prepared by Doré Copper by selecting 34 diamond drill holes which

intersected mineralized zones within the Corner Bay Mineral

Resource estimate (“MRE”) (Figure 1; one mineralized sample was

outside the current MRE). The core material selected represented

different rock types: semi and massive sulphides, quartz veins,

diorite dyke, and fresh and altered anorthosite. The drill core was

sampled by cutting a quarter split NQ core. The longer pieces of

quarter split core were further manually broken down into 1 to 3

inches length to simulate a crushed product. The composite sample

weighted 202 kg and graded 2.20% Cu (Test 4 in table above) and

included an 18% external mining dilution from the hanging wall and

foot wall of the mineralized interval.

The PEA did not include the silver and

molybdenum content (currently excluded from the MRE). The composite

sample indicated silver and molybdenum grades that would be

expected in the deposit (Test 4 in table above).

Substantial Benefits of Ore

Sorting

As already indicated in the Company’s PEA (May

10, 2022), ore sorting technology offers substantial benefits

versus conventional processing. It will reduce operating costs for

milling, flotation and tailings management due to a significant

rejection of low-grade material. Sorting is expected to decrease

the hardness of the ore sent to the mill (lower Bond Work Index of

the sorter pre-concentrate product compared to the feed), and so,

non-negligeable energy savings could be foreseen. The commensurate

increase in the head grade of the ore that will report to the

flotation circuit has the potential to result in improved

metallurgical recoveries in the flotation circuit and higher

concentrate grades.

Further metallurgical and environmental testing,

including comminution, flotation and leachability testing, will be

carried out to progress the feasibility study and ongoing

permitting.

Figure 1. Sample Location for Composite

Sample Used in Ore Sorting Test

Qualified Person

Ernest Mast, P.Eng., President and CEO of the

Corporation, and a "Qualified Person" within the meaning of

National Instrument 43-101 – Standards of Disclosure for Mineral

Projects, has reviewed and approved the scientific and technical

information contained in this news release.

About Steinert

Steinert is a global provider of intelligent

sorting and separation solutions for the recycling and mining

industries. Steinert, has over 125 years of experience, excels at

providing customers technologically advanced sorting solutions via

its extensive process and industry knowledge.

Steinert has been a pioneer in the market,

consistently pursuing and achieving its goal of supporting

customers by being a global technology leader. Founded in 1889 in

Cologne, Germany, Steinert is the only manufacturer of magnetic

separators that has further advanced its classic field of activity

and established sensor-based sorting as a new technology in its

product development.

For more information, please visit:

https://steinertglobal.com/

About Doré Copper Mining

Corp.

Doré Copper Mining Corp. aims to be the next

copper producer in Québec with an initial production target of +50

Mlbs of copper equivalent annually by implementing a hub-and-spoke

operation model with multiple high-grade copper-gold assets feeding

its centralized Copper Rand mill1. The Company has delivered its

PEA in May 2022 and is proceeding with a feasibility study.

The Company has consolidated a large land

package in the prolific Lac Doré/Chibougamau and Joe Mann mining

camps that has historically produced 1.6 billion pounds of

copper and 4.4 million ounces of gold2 The land package

includes 13 former producing mines, deposits and resource target

areas within a 60-kilometre radius of the Company's Copper Rand

Mill.

For further information, please contact:

|

Ernest Mast |

Laurie Gaborit |

|

President and Chief Executive Officer |

Vice President, Investor Relations |

|

Phone: (416) 792-2229 |

Phone: (416) 219-2049 |

|

Email: ernest.mast@dorecopper.com |

Email: laurie.gaborit@dorecopper.com |

Visit: www.dorecopper.com Facebook: Doré Copper MiningLinkedIn:

Doré Copper Mining Corp.Twitter: @DoreCopperInstagram:

@DoreCopperMining

- Technical report titled

"Preliminary Economic Assessment for the Chibougamau Hub-and-Spoke

Complex, Québec, Canada" dated June 15, 2022, in accordance with

National Instrument 43-101 – Standards of Disclosure for

Mineral Projects. The Technical Report was prepared by BBA Inc.

with several consulting firms contributing to sections of the

study, including SLR Consulting (Canada) Ltd., SRK Consulting

(Canada) Inc. and WSP Inc.

- Sources for historic production

figures: Economic Geology, v. 107, pp. 963–989 - Structural and

Stratigraphic Controls on Magmatic, Volcanogenic, and Shear

Zone-Hosted Mineralization in the Chapais-Chibougamau Mining Camp,

Northeastern Abitibi, Canada by François Leclerc et al. (Lac

Dore/Chibougamau mining camp) and NI 43-101 Technical Report on the

Joe Mann Property dated January 11, 2016 by Geologica

Groupe-Conseil Inc. for Jessie Ressources Inc. (Joe Mann mine).

Doré Ramp November 1992 Summary, internal Westminer Report.

Cautionary Note Regarding

Forward-Looking StatementsThis news release includes

certain "forward-looking statements" under applicable Canadian

securities legislation. Forward-looking statements include

predictions, projections and forecasts and are often, but not

always, identified by the use of words such as "seek",

"anticipate", "believe", "plan", "estimate", "forecast", "expect",

"potential", "project", "target", "schedule", "budget" and "intend"

and statements that an event or result "may", "will", "should",

"could" or "might" occur or be achieved and other similar

expressions and includes the negatives thereof. All statements

other than statements of historical fact included in this news

release, including, without limitation, statements with respect to

the timing and ability of the Company to receive necessary

regulatory approvals, the Company's ability to meet its production

target, the commencement, timing and completion of a feasibility

study, and the plans, operations and prospects of the Company and

its properties are forward-looking statements. Forward-looking

statements are necessarily based upon a number of estimates and

assumptions that, while considered reasonable, are subject to known

and unknown risks, uncertainties and other factors which may cause

actual results and future events to differ materially from those

expressed or implied by such forward-looking statements. Such

factors include, but are not limited to, actual exploration

results, changes in project parameters as plans continue to be

refined, future metal prices, availability of capital and financing

on acceptable terms, general economic, market or business

conditions, uninsured risks, regulatory changes, delays or

inability to receive required regulatory approvals, health

emergencies, pandemics and other exploration or other risks

detailed herein and from time to time in the filings made by the

Company with securities regulators. Although the Company has

attempted to identify important factors that could cause actual

actions, events or results to differ from those described in

forward-looking statements, there may be other factors that cause

such actions, events or results to differ materially from those

anticipated. There can be no assurance that such statements will

prove to be accurate, as actual results and future events could

differ materially from those anticipated in such statements.

Accordingly, readers should not place undue reliance on

forward-looking statements. The Company disclaims any intention or

obligation to update or revise any forward-looking statements,

whether as a result of new information, future events or otherwise,

except as required by law.

Neither TSX Venture Exchange nor its

Regulation Services Provider (as that term is defined in the

policies of the TSX Venture Exchange) accepts responsibility for

the adequacy or accuracy of this news release.

A photo accompanying this announcement is available at

https://www.globenewswire.com/NewsRoom/AttachmentNg/ad940cd4-8e03-4452-8559-73557b7889c7

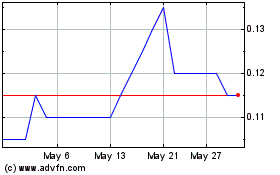

Dore Copper Mining (TSXV:DCMC)

Historical Stock Chart

From Nov 2024 to Dec 2024

Dore Copper Mining (TSXV:DCMC)

Historical Stock Chart

From Dec 2023 to Dec 2024