Green Shift Commodities Ltd. (

TSXV:

GCOM), (“

Green Shift” or the

“

Company”) is pleased to announce the results of

further test work that show membrane technology being utilized for

testing at the Company’s Berlin Deposit to be highly efficient in

separating uranium, battery commodities and rare earth elements

found in the Company’s Berlin Deposit (“

Berlin”).

Prior test work showed that not only could membranes significantly

reduce the size of the processing plant but could simplify the

recovery of phosphoric acid in comparison to the design modelled in

the previous economic assessment of the Project completed in 2013.

The current reported results are from tests undertaken during the

second phase of a three-phase testing program, completed earlier

this year.

Highlights

- The test work was successful in

achieving uranium, nickel, vanadium and rare earth element

recoveries of over 95%.

- Phosphoric acid recovery is

comparatively lower and other membranes will be tested to improve

its recovery.

- The greater efficiency of membranes

in separating rare earth elements could significantly increase the

potential of the Berlin Deposit.

Trumbull Fisher, Director, and CEO commented,

“We are very pleased and encouraged by the improved recoveries

achieved by membranes in recovering the green energy metals during

metallurgical testing on our Berlin asset. This asset contains

commodities that are critical to the global green movement as we

drive towards cleaner sources of energy and energy storage. In

addition, we continue to seek other battery metal assets that would

compliment Berlin’s core commodities and be accretive to our

Company’s vision of becoming a go-to source of clean energy

commodities.”

Membrane Efficiency

Test work completed to date demonstrates that

membrane separation is a highly efficient process at concentrating

uranium, nickel, vanadium, rare earth elements, molybdenum and zinc

from a liquid that was synthesized to match the pregnant leach

solution (“PLS”) – the liquid generated from leaching the

mineralized rock - from the Berlin Deposit. The results show that

metals are effectively separated from the PLS. While phosphoric

acid recovery is not as good with the selected membranes, further

work will consider options to improve this – aiming for a target

range of 80% to 90% recovery.

Table 1. Results of membrane test work

showing the efficiency of metals and phosphate recovery from a

pregnant liquor solution that simulated a PLS from the Berlin

Deposit.

|

Commodity |

Percentage Recovery |

|

Option A |

Option B |

|

Uranium |

97.1 |

99.7 |

|

Nickel |

97.5 |

99.9 |

|

Vanadium |

97.0 |

99.9 |

|

Phosphoric acid |

79.3 |

63.6 |

|

Rare Earth Elements |

98.5 |

99.7 |

|

Molybdenum |

86.5 |

97.6 |

|

Zinc |

96.6 |

99.9 |

|

|

|

|

|

Flow Rate Reduction (%) |

90.2 |

81.2 |

Next Steps

- In response to the rapid adoption

of lithium ferro-phosphate (“LFP”) as safe, reliable batteries by

the electric vehicle industry, it is a priority for the Company to

assess the potential costs/benefits of producing ferro-phosphate

from Berlin. It will be assessed as to whether the phosphate from

Berlin can be combined with iron to form ferro-phosphate for LFP

batteries, rather than simply producing phosphoric acid as was

originally contemplated.

- The rapid advances in sensor-based

sorting technology requires that this be tested on mineralized

material from Berlin. This technology uses scanners to detect

physical and or chemical characteristics of mineral-bearing

components of the crushed rock as it emerges from the mine and uses

a jet of compressed air to remove the mineralized fragments from

waste fragments. If this technology works on mineralized material

from Berlin, it could significantly enhance the efficiency, and

could potentially lower operating costs, of a future processing

plant.

- Further work is planned to strive

to improve the recovery of phosphoric acid from the 63%-70%

achieved so far to a target range of 80% to 90%.

Qualified Person

The information related to membrane systems in

this news release has been verified and approved by Johann van der

Westhuysen, MEng, BEng, Managing Director of Synexus (Pty) Ltd, a

process engineering services company that specializes in membrane

separation applications in hydrometallurgy. Mr. Van der Westhuysen

is registered as a Professional Engineer (PrEng) (Chemical) with

the Engineering Council of South Africa and as a Chartered Chemical

Engineer (CEng) with the Institution of Chemical Engineers,

Engineering Council of the United Kingdom. Through this

designation, Mr. Van der Westhuysen is a Qualified Person (“QP”) as

defined by National Instrument 43-101, Standards of Disclosure for

Mineral Projects of the Canadian Securities Administrators. The

synthetic PLS was prepared by, and the membrane test work conducted

under the direct control of, the QP. All test samples were

submitted under chain-of-custody for analyses at an accredited

laboratory, and all analytical results were received directly by

the QP. The data analysis and the opinions expressed on the data

are those of the QP.

For further information on the Berlin deposit,

refer to the technical report entitled “Technical Report on the

Berlin Uranium – Battery Commodity Deposit, Colombia” dated April

25, 2022, which is available under the Company’s profile on SEDAR

at www.sedar.com.

About Green Shift Commodities

Ltd.

Green Shift Commodities Ltd. is focused on the

exploration and development of commodities needed to help

decarbonize and meet net-zero goals.

The Company is developing the Berlin Deposit in

Colombia. Apart from uranium, for clean nuclear energy, the Berlin

Deposit contains battery commodities including nickel, phosphate,

and vanadium. Phosphate is a key component of lithium-ion

ferro-phosphate (“LFP”) batteries that are being used by a growing

list of electric vehicle manufacturers. Nickel is a component of

various lithium-ion batteries, while vanadium is the element used

in vanadium redox flow batteries. Neodymium, one of the rare earth

elements contained within the Berlin Deposit, is a key component of

powerful magnets that are used to increase the efficiency of

electric motors and in generators in wind turbines.

For further information, please

contact:

Trumbull Fisher, CEO, Green Shift Commodities

Ltd.E: tfisher@greenshiftcommodities.comTel: (416) 917-5847

Forward-Looking Statements

This news release includes certain “forward

looking statements”. Forward-looking statements consist of

statements that are not purely historical, including statements

regarding beliefs, plans, expectations or intensions for the

future, and include, but not limited to, statements with respect

to: the potential metallurgical recoveries and results of the test

work; the potential for improving the recovery of phosphate; the

successful reactivation of the Berlin Project; the future direction

of the Company’s strategy; and other activities, events or

developments that are expected, anticipated or may occur in the

future. These statements are based on assumptions, including that:

(i) the ability to achieve positive outcomes from test work; (ii)

actual results of our exploration, resource goals, metallurgical

testing, economic studies and development activities will continue

to be positive and proceed as planned, (iii) requisite regulatory

and governmental approvals will be received on a timely basis on

terms acceptable to Green Shift Commodities Ltd. (iv) economic,

political and industry market conditions will be favourable, and

(v) financial markets and the market for uranium, battery

commodities and rare earth elements will continue to strengthen.

Such statements are subject to risks and uncertainties that may

cause actual results, performance or developments to differ

materially from those contained in such statements, including, but

not limited to: (1) changes in general economic and financial

market conditions, (2) changes in demand and prices for minerals,

(3) the Company’s ability to source commercially viable

reactivation transactions and / or establish appropriate joint

venture partnerships, (4) litigation, regulatory, and legislative

developments, dependence on regulatory approvals, and changes in

environmental compliance requirements, community support and the

political and economic climate, (5) the inherent uncertainties and

speculative nature associated with exploration results, resource

estimates, potential resource growth, future metallurgical test

results, changes in project parameters as plans evolve, (6)

competitive developments, (7) availability of future financing, (8)

the effects of COVID-19 on the business of the Company, including,

without limitation, effects of COVID-19 on capital markets,

commodity prices, labour regulations, supply chain disruptions and

domestic and international travel restrictions, (9) exploration

risks, and other factors beyond the control of Green Shift

Commodities Ltd. including those factors set out in the “Risk

Factors” in our Management Discussion and Analysis dated May 2,

2022 for the fiscal year ended December 31, 2021 available on SEDAR

at www.sedar.com. Readers are cautioned that the assumptions used

in the preparation of such information, although considered

reasonable at the time of preparation, may prove to be imprecise

and, as such, undue reliance should not be placed on

forward-looking statements. Green Shift Commodities Ltd. assumes no

obligation to update such information, except as may be required by

law.

Neither the TSX Venture Exchange nor its

Regulation Services Provider (as that term is defined in the

policies of the TSX Venture Exchange) accepts responsibility for

the adequacy or accuracy of this press release.

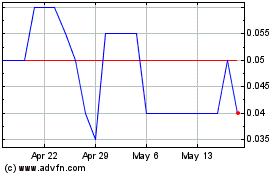

Green Shift Commodities (TSXV:GCOM)

Historical Stock Chart

From Dec 2024 to Jan 2025

Green Shift Commodities (TSXV:GCOM)

Historical Stock Chart

From Jan 2024 to Jan 2025