New report confirms Smith+Nephew’s OXINIUM™ Technology is the best performing bearing surface at 20 years for total hip arthroplasty

March 06 2025 - 9:00AM

Smith+Nephew (LSE:SN, NYSE:SNN), the global medical technology

company, is pleased to announce that the latest annual report from

the Australian Orthopaedic Association National Joint Replacement

Registry (AOANJRR) highlights the exceptional performance of

Smith+Nephew’s proprietary OXINIUM on highly cross-linked

polyethylene. The data indicates that this combination has the

highest survivorship rate (94.1%) among all bearing combinations

over a 20-year period for total hip arthroplasty (THA).1

The report on 20-year outcomes corroborates similar findings and

peer-reviewed publications from the National Joint Registry for

England, Wales, Northern Ireland and the Isle of Man (NJR).2

Whitehouse et al. found that hip implants combining delta ceramic

or OXINIUM (Oxidized Zirconium) heads with XLPE (highly

cross-linked polyethylene) liners or cups had the lowest risk of

needing revision surgery over a 15-year period.3

Four registries in total - including the Italian Registry (RIPO;

Register of Orthopaedic Prosthetic Implants) and the Dutch

Arthroplasty Register (LROI) - have now demonstrated that

OXINIUM/XLPE had a 35% lower risk of revision at 10-years versus

other modular acetabular implants1-5

These findings offer valuable guidance for surgeons and patients

in selecting the most reliable implant materials for long-term

outcomes. “When I started in practice more than 20 years ago

bearing wear was the leading cause of failure of hip replacements,”

said Prof. Bill Walter of The University of Sydney and Royal North

Shore Hospital. “We used to see osteolysis as the main reason for

revision. The AOANJRR now shows that bearing wear has been

virtually eliminated as a cause of failure. The bearing combination

of OXINIUM on highly cross-linked polyethylene leads the pack with

revision rates at 20 years significantly lower than even metal on

XLPE.”

Through a unique manufacturing process, the OXINIUM alloy

becomes a ceramicised metal - a true material transformation -

rather than an applied coating.6 It is this material transformation

that provides OXINIUM with its ground-breaking performance benefits

which include:

- Unrivalled

Material Science: The durability of metal, the wear resistance

of ceramic and corrosion resistance better than both metal and

ceramic.6-16

- Differentiated

Composition: Virtually no nickel, cobalt and chromium,16 with a

30x reduction in pro-inflammatory markers for OXINIUM.*17 As

such, OXINIUM implants do not require declaration of the presence

of CMR (carcinogenic, mutagenic, reprotoxic) substances on the

labeling.

“Registries throughout the world have highlighted the

performance of OXINIUM for total hip arthroplasty. The AOANJRR

report showing 20-year outcomes provides powerful evidence for

payers, hospitals, surgeons, and patients of our truly

differentiated and proven technology,” said Craig Gaffin, President

of Global Orthopaedics at Smith+Nephew. “OXINIUM/XLPE continues to

demonstrate superior revision rates across multiple global joint

replacement registries.”

To learn more about Smith+Nephew’s OXINIUM Technology and hip

reconstruction portfolio, please visit our booth (#3729) at the

American Academy of Orthopaedic Surgeons Annual Meeting in San

Diego March 11-13, 2025 or

visit https://www.smith-nephew.com/en-us/health-care-professionals/products/orthopaedics/oxinium.

- ends –

Media Enquiries

Dave Snyder +1

(978) 749-1440

Smith+Nephew

david.snyder@smith-nephew.com

* ASTM International Standard Specification

for Wrought Zirconium-2.5 Niobium Alloy for Surgical Implant

Applications (UNS R60901) Designation: F 2384 – 10.

References

- Australian Orthopaedic Association National Joint Replacement

Registry (AOANJRR) Hip, Knee & Shoulder Arthroplasty: 2024

Annual Report Adelaide; AOA, 2024:1–629. Available at:

https://aoanjrr.sahmri.com/annual-reports-2024. Accessed December

11, 2024

- National Joint Registry for England, Wales and Northern

Ireland: 21st Annual Report. 2024. Available at: NJR 21st Annual

Report 2024_Hips.pdf. Accessed January 06, 2025.

- Whitehouse MR, Patel R, French JMR, et al. The association of

bearing surface materials with the risk of revision following

primary total hip replacement: A cohort analysis of 1,026,481 hip

replacements from the National Joint Registry. PLoS Med

2024;21(11): e1004478.

- Peters RM, Van Steenbergen LN, Stevens M, Rijk PC, Bulstra SK,

Zijlstra WP. The effect of bearing type on the outcome of total hip

arthroplasty. Acta Orthop. 2018:89;163–169. Available at:

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC5901513/. Accessed

November 9, 2023.

- Atrey A, Ancarani C, Fitch D, Bordini B. Impact of bearing

couple on long-term component survivorship for primary cementless

total hip replacement in a large arthroplasty registry. Poster

presented at: Canadian Orthopedic Association; June 20–23, 2018;

Victoria, British Columbia, Canada.

- Hunter G, Dickinson J, Herb B, et al. Creation of oxidized

zirconium orthopaedic implants. Journal of ASTM International.

2005;2:1-14.

- Long M, Riester L, Hunter G. Nano-hardness Measurements of

Oxidized Zr-2.5Nb and Various Orthopaedic Materials. Abstract

presented at: 24th Annual Meeting of the Society for Biomaterials.

April 22-26, 1998, San Diego, California.

- Parikh A, Hill P, Hines G, Pawar V. Wear of conventional and

highly crosslinked polyethylene liners during simulated fast

walking/jogging. Poster presented at: Orthopaedic Research Society

Annual Meeting; 2009; Las Vegas; NV.

- Parikh A, Hill P, Pawar V, Sprague J. Long-term Simulator Wear

Performance of an Advanced Bearing Technology for THA. Poster

presented at: 2013 Annual Meeting of the Orthopaedic Research

Society. Poster no. 1028.

- Papannagari R, Hines G, Sprague J, Morrison M. Long-term wear

performance of an advanced bearing technology for TKA. Poster

presented at: Orthopaedic Research Society Annual Meeting; 2011;

Long Beach, CA.

- Smith+Nephew 2010. OR-10-155.

- Aldinger P, Williams T, Woodard E. Accelerated fretting

corrosion testing of zirconia toughened alumina composite ceramic

and a new composition of ceramicised metal femoral heads. Poster

presented at: Orthopaedic Research Society Annual Meeting; 2017;

San Diego, CA.

- Smith+Nephew 2016. OR-16-127.

- 2005 ASM International Engineering Materials Achievement

Award.

- Dalal A, Pawar V, McAllister K, Weaver C, Hallab NJ. Orthopedic

implant cobalt-alloy particles produce greater toxicity and

inflammatory cytokines than titanium alloy and zirconium

alloy-based particles in vitro, in human osteoblasts, fibroblasts,

and macrophages. J Biomed Mater Res Part A.

2012;100A:2147-2158.

- ASTM F2384-24 (May 2024). Standard specification for wrought

zirconium-2.5niobium alloy for surgical implant applications (UNS

R60901). Available at: https://www.astm.org/f2384-10r16.html.

Accessed February 27, 2025

- Hallab NJ, McAllister K, Jacobs JJ, and Pawar, V.

Zirconium-Alloy and Zirconium-Oxide Particles Produce less Toxicity

and Inflammatory Cytokines than Cobalt-Alloy and Titanium-Alloy

Particles In Vitro, in Human Osteoblasts, Fibroblasts and

Macrophages. 2012 Annual Meeting of the Orthopaedic Research

Society. Poster no. 0971.

About Smith+Nephew

Smith+Nephew is a portfolio medical technology business focused

on the repair, regeneration and replacement of soft and hard

tissue. We exist to restore people’s bodies and their self-belief

by using technology to take the limits off living. We call this

purpose ‘Life Unlimited’. Our 17,000 employees deliver this mission

every day, making a difference to patients’ lives through the

excellence of our product portfolio, and the invention and

application of new technologies across our three global business

units of Orthopaedics, Sports Medicine & ENT and Advanced Wound

Management.

Founded in Hull, UK, in 1856, we now operate in around 100

countries, and generated annual sales of $5.8 billion in 2024.

Smith+Nephew is a constituent of the FTSE100 (LSE:SN, NYSE:SNN).

The terms ‘Group’ and ‘Smith+Nephew’ are used to refer to Smith

& Nephew plc and its consolidated subsidiaries, unless the

context requires otherwise.

For more information about Smith+Nephew, please visit

www.smith-nephew.com and follow us on X, LinkedIn, Instagram or

Facebook.

Forward-looking Statements

This document may contain forward-looking statements that may or

may not prove accurate. For example, statements regarding expected

revenue growth and trading profit margins, market trends and our

product pipeline are forward-looking statements. Phrases such as

"aim", "plan", "intend", "anticipate", "well-placed", "believe",

"estimate", "expect", "target", "consider" and similar expressions

are generally intended to identify forward-looking statements.

Forward-looking statements involve known and unknown risks,

uncertainties and other important factors that could cause actual

results to differ materially from what is expressed or implied by

the statements. For Smith+Nephew, these factors include: conflicts

in Europe and the Middle East, economic and financial conditions in

the markets we serve, especially those affecting healthcare

providers, payers and customers; price levels for established and

innovative medical devices; developments in medical technology;

regulatory approvals, reimbursement decisions or other government

actions; product defects or recalls or other problems with quality

management systems or failure to comply with related regulations;

litigation relating to patent or other claims; legal and financial

compliance risks and related investigative, remedial or enforcement

actions; disruption to our supply chain or operations or those of

our suppliers; competition for qualified personnel; strategic

actions, including acquisitions and disposals, our success in

performing due diligence, valuing and integrating acquired

businesses; disruption that may result from transactions or other

changes we make in our business plans or organisation to adapt to

market developments; relationships with healthcare professionals;

reliance on information technology and cybersecurity; disruptions

due to natural disasters, weather and climate change related

events; changes in customer and other stakeholder sustainability

expectations; changes in taxation regulations; effects of foreign

exchange volatility; and numerous other matters that affect us or

our markets, including those of a political, economic, business,

competitive or reputational nature. Please refer to the documents

that Smith+Nephew has filed with the U.S. Securities and Exchange

Commission under the U.S. Securities Exchange Act of 1934, as

amended, including Smith+Nephew's most recent annual report on Form

20-F, which is available on the SEC’s website at www. sec.gov, for

a discussion of certain of these factors. Any forward-looking

statement is based on information available to Smith+Nephew as of

the date of the statement. All written or oral forward-looking

statements attributable to Smith+Nephew are qualified by this

caution. Smith+Nephew does not undertake any obligation to update

or revise any forward-looking statement to reflect any change in

circumstances or in Smith+Nephew's expectations.

◊ Trademark of Smith+Nephew. Certain marks registered in US

Patent and Trademark Office.

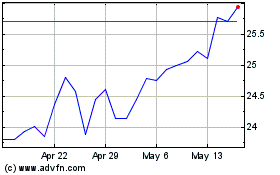

Smith and Nephew (NYSE:SNN)

Historical Stock Chart

From Feb 2025 to Mar 2025

Smith and Nephew (NYSE:SNN)

Historical Stock Chart

From Mar 2024 to Mar 2025