Australia’s Federal Minister for Industry and Science Opens Li-S Energy Battery Plant and Announces $AUD1.7M Industry Growth Program Grant

August 12 2024 - 8:00AM

Business Wire

Australian battery technology company Li-S Energy (ASX:LIS) has

officially launched its new 2MWh lithium sulfur and lithium metal

battery production facility at Geelong, Victoria, Australia. Li-S

Energy will also start producing lithium foils and laminates at the

facility after receiving a government grant.

This press release features multimedia. View

the full release here:

https://www.businesswire.com/news/home/20240812342742/en/

Australia's Federal Minister for Industry

and Science Ed Husic officially opens the Li-S Energy Phase 3

Facility - Australia’s largest pouch cell production line - (L to

R) Li-S Energy CEO Dr Lee Finniear, Hon. Ed Husic MP, Hon. Libby

Coker MP. The new state-of-the-art Li-S Energy pouch cell

production facility in Geelong, Victoria that was officially opened

by Minister Husic is the largest of its kind in Australia,

installed inside Australia’s largest battery dry room. Built at a

cost of over $10 million, the facility spans the entire production

process from creating and coating cathode powders to final cell

fabrication and testing. (Photo: Business Wire)

The official opening was hosted by Li-S Energy CEO Dr Lee

Finniear, Australia’s Federal Minister for Industry and Science,

the Hon. Ed Husic MP, and Federal MP for Corangamite, the Hon.

Libby Coker.

During the event, the Minister announced that Li-S Energy had

been awarded an Industry Growth Program (IGP) Commercialisation and

Growth Grant of $AUD1.7 million to develop Australia’s first

lithium foil production facility.

A short video of the visit can be found online.

Li-S Energy is an Australian company, commercialising unique

Australian IP from Deakin University for lithium sulfur and lithium

metal batteries, which are far lighter than the comparable

lithium-ion batteries.

The batteries offer key performance advantages where weight is

critical, such as in drones, electric aviation and defence

applications.

The new state-of-the-art Li-S Energy pouch cell production

facility is the largest in Australia and is installed inside

Australia’s largest battery dry room. Built at a cost of over

$AUD10 million, the facility spans the entire production process

from creating and coating cathode powders to final cell fabrication

and testing.

With the support of the Grant, Li-S Energy plans to extend

beyond its cell manufacturing capability to produce high-quality

lithium foils and laminates from lithium metal ingots.

Lithium metal foil is used as the anode for both lithium sulfur

and lithium metal batteries, but the current imported supply has

limited quality and is not optimised for Li-S cells.

Beyond using the lithium foil in its batteries, the Company

intends to export the foils internationally as an additional

revenue stream to capitalise on this growing market.

Dr Lee Finniear, CEO of Li-S Energy, said Australia currently

produced 52% of the world’s lithium ore, yet much of this is

exported without adding additional value.

“With global demand for lithium metal foil forecast to reach

US$51 billion by 2032, Australia has a unique opportunity to

capitalise on this emerging market to produce lithium foils here,

adding value here before exporting this high-value product to

global markets,” he said.

View source

version on businesswire.com: https://www.businesswire.com/news/home/20240812342742/en/

Media enquiries to ben@rgcmm.com.au.

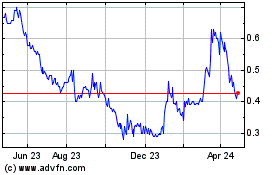

Lithium South Development (TSXV:LIS)

Historical Stock Chart

From Oct 2024 to Nov 2024

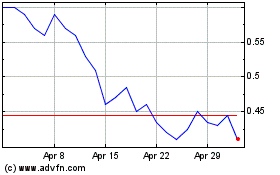

Lithium South Development (TSXV:LIS)

Historical Stock Chart

From Nov 2023 to Nov 2024