TIDMRSG

RNS Number : 0285N

Resolute Mining Limited

27 January 2021

27 January 2021

Tabakoroni Underground Mineral Resource grows to 1.26 million

ounces at 4.9g/t gold

Highlights

-- Tabakoroni Underground Mineral Resource Estimate updated to

8.1 million tonnes at 4.9 g/t for 1.26 million ounces of gold

-- High-grade results from new drilling informing the updated

resource at Tabakoroni Deeps include:

o TADD817 - 26m @ 9.69g/t from 302m

o TADD833 - 18m @ 11.20g/t from 317m

-- Drilling to continue throughout 2021 to build the resources

and reserves of Tabakoroni to strengthen the financial case for a

future underground mine development

-- An updated life of mine feasibility study is being compiled

utilising the expanded Tabakoroni Resource

Resolute Mining Limited (ASX/LSE: RSG) (Resolute or the Company)

is pleased to announce an updated Mineral Resource Estimate from

ongoing exploration success at Tabakoroni, confirming the potential

for a new underground gold mine at Syama in Mali.

The Tabakoroni Mineral Resource has been upgraded to 8.1 million

tonnes (Mt) at 4.9 grams per tonne (g/t) gold (Au) for a total of

1.26 million ounces (Moz)

The mineralisation at Tabakoroni remains open both along strike

and at depth and continued exploration success is expected to

expand Mineral Resources and further extend mine life.

Updated Tabakoroni Underground Mineral Resource Estimate

Resolute published the Maiden Underground Resource at Tabakoroni

on 29 April 2019 comprising 5.2Mt @ 5.1g/t Au for 850,000oz.

Following continued exploration success, the Resource was updated

on 14 October 2020 with an increase to 1Moz of gold from a Mineral

Resource of 7.4Mt @ 4.4g/t Au.

The announcement on 14 October 2020 also reported several

high-grade intersections underneath the Namakan and South oxide

pits at Tabakoroni which were located outside of the October 2020

resource estimate.

Diamond drilling in the second half of 2020 identified a

coherent high-grade lens of mineralisation located underneath the

South oxide pit at Tabakoroni. The first intersections in this zone

were reported in the 14 October 2020 announcement. Subsequent

drilling activities focussed on fully outlining this new zone which

was ultimately successful with the return of a number of additional

high-grade results including:

-- TADD817 - 26m @ 9.69g/t from 302m

-- TADD833 - 18m @ 11.20g/t from 317m

The locations of these drill intersection pierce points are

shown in Figure 1.

The combination of the new high-grade mineralisation underneath

the South oxide pit and additional ore grade drill intersections

returned underneath the Namakan pit combined to dramatically

increase the tonnage in the global resource estimate. This update

continues the trend from previous announcements showing the

underground Resource at Tabakoroni continues to steadily grow. The

Global Mineral Resource is shown in Table 1.

Tabakoroni Underground Resource

Global Mineral Resource

--------------------------------------

Cut-off Tonnes Gold Ounces

grade

----------

(000)s (g/t) (000s)

---------- -------- ------ --------

1.5 13,130 4.01 1,690

-------- ------ --------

1.75 12,050 4.23 1,640

-------- ------ --------

2 10,720 4.52 1,560

-------- ------ --------

2.5 8,850 5 1,420

-------- ------ --------

3 6,890 5.63 1,250

-------- ------ --------

Table 1: Tabakoroni Global Mineral Resources

Following the Tabakoroni Pre-Feasibility Study which was

reported with the 14 October 2020 Resource update it was decided to

apply the more rigorous principles of Reasonable Prospects of

Eventual Economic Extraction (RPEEE) for the published Mineral

Resource. The Global Mineral Resource was restricted by a stope

shape optimisation completed in Deswik Stope Optimizer to produce a

set of potentially economical stope shape wireframes. The Mineral

Resource then reported the mineralised blocks within these

optimised stope shape wireframes. The Mineral Resource is therefore

reported excluding dilution (undiluted).

The optimisation was completed at a resource gold price of

US$2,000/oz and considered likely mining and processing parameters

to be encountered during eventual extraction of the material, such

as the most likely mining method (long hole open stoping) and

approximate mining and metallurgical parameters. The RPEEE

constrained Mineral Resource is shown in Table 2.

Tabakoroni Underground Resource

Category Tonnes Gold Ounces

(000)s (g/t) (000s)

-------- ------ -------

Measured 210 4.39 30

-------- ------ -------

Indicated 4,440 4.89 700

-------- ------ -------

Inferred 3,460 4.82 540

-------- ------ -------

Total 8,110 4.85 1,260

-------- ------ -------

Table 2: Tabakoroni Underground Mineral Resources

As expected, the Mineral Resource has lower tonnes and higher

grade than the Global Mineral Resource at the same cut-off

grade.

The Resource block model and significant intersections are shown

in Figure 1.

Please see image in the full version of the announcement at

www.rml.com.au

Figure 1: Tabakoroni Longitudinal Section with Mineral Resource

block model and drill intersections

Resource estimation and Classification methodology

A structural geology model was completed during 2020 and this

model guided the update of the mineralised wireframes which

increased the confidence in the estimation. The wireframes were

created with a cut-off grade of 10 g/t Au and a minimum downhole

thickness of 2m.

Four domains have been identified at Tabakoroni. The main domain

is the Tabakoroni Main Shear Zone (TMSZ), which is a steeply

dipping shear mineralised over 1.8km of strike. A second domain was

created for the parallel lodes adjacent to the TMSZ, and there are

a number of shear-parallel smaller lodes.

Another domain was created for the shallow westerly-dipping

lodes in the southern and central portion of the deposit. These

lodes are dipping at 45deg and appear to overprint the TMSZ close

to the surface. The final domain created was the steeply dipping

mineralisation in the north-eastern portion of the deposit, which

strikes at 20deg to the northeast.

Gold, sulphide sulphur, organic carbon and arsenic was estimated

into a three-dimensional block model using Ordinary Kriged (OK)

methodology.

Top cutting was required to reduce the influence of outlier

values. Variograms were generated for the mineralised one metre

composites. Optiro Pty Ltd (Optiro) carried out kriging

neighbourhood analysis based upon the gold variograms to optimise

the estimation parameters, and these parameters were used for

ordinary kriging into the 5m x 10m x 5m parent cells.

Density was assigned based on weathering codes; 2,190

measurements were taken from diamond hole samples. These

measurements suggested a density of 2.72g/m(3) for the fresh,

2.38g/m(3) for the transitional material and 2.12g/m(3) for the

oxide material.

The estimation was validated and then classified as Measured,

Indicated and Inferred in accordance with the JORC Code (2012)

reporting guidelines. The structural interpretation has further

increased the confidence in the location and orientation of the

mineralisation and therefore the estimation. The default

classification for the mineralisation is an Inferred Mineral

Resource. Measured Mineral Resources are defined by contiguous

zones where the nominal drillhole density is 12.5m by 12.5m, while

an Indicated Mineral Resource has been defined by zones where the

nominal drillhole density is up to 50m by 50m. The resource has

been depleted for mining as of 31 December 2020.

Further Exploration opportunities at Tabakoroni

Ongoing Tabakoroni Exploration

Drilling completed since the 14 October 2020 Mineral Resource

Estimate was predominantly an extensional program to increase the

global resources. This program was successful with the resource

nearly doubling from the previous announcement. Some of the

expanded resources are located beneath to South pit. In this area

the new resources are nearly all classified as Inferred therefore

cannot be used to quote reserves.

The drilling program for 2021 will concentrate on infilling and

expanding the high-grade mineralisation underneath the South pit at

Tabakoroni. A drill density of 50m centres will be required to

classify this new zone as Indicated Resources.

Drilling in 2021 will also follow up the deep intersection in

TADD781 of 9m @ 5.24g/t Au located on the extreme northern end of

the TMSZ. This intersection was reported previously and is located

well outside the current resource envelope.

For further information, contact:

Stuart Gale

Interim CEO

Resolute Mining Limited

Telephone: +61 8 9261 6100 | Email: contact@rml.com.au

Contact Information

Resolute Berenberg (UK Corporate Broker)

Stuart Gale Interim CEO Matthew Armitt / Jennifer Wyllie / Detlir

Telephone: +61 8 9261 6100 Elezi

Email: contact@rml.com.au Telephone: +44 20 3207 7800

Web: www.rml.com.au Tavistock (UK Public Relations)

Jos Simson / Emily Moss / Annabel de Morgan

/ Oliver Lamb

Telephone: +44 207 920 3150 / +44 778

855 4035

Email: resolute@tavistock.co.uk

Board of Directors Contact

Mr Martin Botha, Non-Executive Ms Sabina Shugg, Non-Executive Stuart Gale, Interim

Chairman Director CEO

T: +618 9261

6100

E: contact@rml.com.au

-----------------------

Ms Yasmin Broughton, Mr Peter Sullivan, Non-Executive

Non-Executive Director Director

-----------------------

Mr Mark Potts, Non-Executive

Director

------------------------------- ----------------------------------- -----------------------

Competent Persons Statement

The information in this report that relates to the Exploration

Results, Mineral Resources and Ore Reserves is based on information

compiled by Mr Bruce Mowat, a member of The Australian Institute of

Geoscientists. Mr Bruce Mowat has more than five years' experience

relevant to the styles of mineralisation and type of deposit under

consideration and to the activity which he is undertaking to

qualify as a Competent Person, as defined in the 2012 Edition of

the "Australasian Code for Reporting of Exploration Results,

Mineral Resources and Ore Reserves" (the JORC Code). Mr Bruce Mowat

is a full-time employee of the Resolute Mining Limited Group and

holds equity securities in the Company. He has consented to the

inclusion of the matters in this report based on his information in

the form and context in which it appears. This information was

prepared and disclosed under the JORC Code 2012 except where

otherwise noted.

The information in this announcement that relates to the Mineral

Resource estimate has been based on information and supporting

documents prepared by Mrs Susan Havlin, a Competent Person who is a

Member of The Australasian Institute of Mining and Metallurgy. Mrs

Havlin is an employee of Optiro and has sufficient experience

relevant to the style of mineralisation and type of deposit under

consideration and to the activity which has been undertaken to

qualify as a Competent Person. Mrs Havlin confirms that the Mineral

Resource estimate is based on information in the supporting

documents and consents to the inclusion in the report of the

Mineral Resource estimate and related content based on the

information in the form and context in which it appears.

Cautionary Statement about Forward-Looking Statements

This announcement includes certain statements, estimates and

projections with respect to the future performances of Resolute.

Such statements, estimates and projections reflect various

assumptions concerning anticipated results, which assumptions may

prove not to be correct. The projections are merely estimates by

Resolute, of the anticipated future performance of Resolute's

business based on interpretations of existing circumstances, and

factual information and certain assumptions of economic results,

which may prove to be incorrect. Such projections and estimates are

not necessarily indicative of future performance, which may be

significantly less favourable than as reflected herein.

Accordingly, no representations are made as to the fairness,

accuracy, correctness or completeness of the information contained

in this announcement including estimates or projections and such

statements, estimates and projections should not be relied upon as

indicative of future value, or as a guarantee of value of future

results. This announcement does not constitute an offer, invitation

or recommendation to subscribe for or purchase securities in

Resolute Mining Limited (ASX/LSE: RSG).

Appendix 1: Recent drilling results

Tabakoroni Deeps Drilling

Hole_ID North East RL Dip Azi EOH From To Width Au

(WGS) (WGS) (m) (WGS) (m) (m) (m) (m) (g/t)

TADD810 1163520 810234 364 -63 54 745.2 482 485 3 2.25

-------- ------- ----- ---- ------- ------ ----- ----- ------ -------

TADD810 1163520 810234 364 -63 54 745.2 503 507 4 3.52

-------- ------- ----- ---- ------- ------ ----- ----- ------ -------

TADD810 1163520 810234 364 -63 54 745.2 597 602 5 1.5

-------- ------- ----- ---- ------- ------ ----- ----- ------ -------

TADD810 1163520 810234 364 -63 54 745.2 607 612 5 5.1

-------- ------- ----- ---- ------- ------ ----- ----- ------ -------

TADD810 1163520 810234 364 -63 54 745.2 643 645 2 3.67

-------- ------- ----- ---- ------- ------ ----- ----- ------ -------

TADD810 1163520 810234 364 -63 54 745.2 672 686 14 3.24

-------- ------- ----- ---- ------- ------ ----- ----- ------ -------

TADD817 1163496 810488 376 -57 58 408.3 181 184 3 2.79

-------- ------- ----- ---- ------- ------ ----- ----- ------ -------

TADD817 1163496 810488 376 -57 58 408.3 228 235 7 3.56

-------- ------- ----- ---- ------- ------ ----- ----- ------ -------

TADD817 1163496 810488 376 -57 58 408.3 302 328 26 9.69

-------- ------- ----- ---- ------- ------ ----- ----- ------ -------

TADD824 1163306 810510 368 -58 64 439.4 162 169 7 3.92

-------- ------- ----- ---- ------- ------ ----- ----- ------ -------

TADD824 1163306 810510 368 -58 64 439.4 306 310 4 1.42

-------- ------- ----- ---- ------- ------ ----- ----- ------ -------

TADD829 1163762 810043 363 -64 57 890.8 684 690 6 2.66

-------- ------- ----- ---- ------- ------ ----- ----- ------ -------

TADD829 1163762 810043 363 -64 57 890.8 845 852 7 1.72

-------- ------- ----- ---- ------- ------ ----- ----- ------ -------

TADD833 1163427 810509 371 -59 61 403.1 134 136 2 9.02

-------- ------- ----- ---- ------- ------ ----- ----- ------ -------

TADD833 1163427 810509 371 -59 61 403.1 181 189 8 1.56

-------- ------- ----- ---- ------- ------ ----- ----- ------ -------

TADD833 1163427 810509 371 -59 61 403.1 317 335 18 11.2

-------- ------- ----- ---- ------- ------ ----- ----- ------ -------

TADD842 1163694 810395 381 -68 66 452.4 298 301 3 7.58

-------- ------- ----- ---- ------- ------ ----- ----- ------ -------

TARC877 1164912 810325 342 -55 67 150 110 113 3 4.24

-------- ------- ----- ---- ------- ------ ----- ----- ------ -------

TARD777 1163200 810543 370 -65 64 519.5 186 192 6 1.93

-------- ------- ----- ---- ------- ------ ----- ----- ------ -------

TARD777 1163200 810543 370 -65 64 519.5 254 259 5 3.24

-------- ------- ----- ---- ------- ------ ----- ----- ------ -------

TARD777 1163200 810543 370 -65 64 519.5 315 322 7 0.79

-------- ------- ----- ---- ------- ------ ----- ----- ------ -------

Notes to accompany table:

-- Grid coordinates are WGS84 Zone 29 North

-- RC intervals are sampled every 1m by dry riffle splitting or

scoop to provide a 1-3kg sample

-- Diamond core are sampled every 1m by cutting the core in half to provide a 2-4kg sample

-- Cut-off grade for reporting of intercepts is >1g/t Au with

a maximum of 3m consecutive internal dilution included within the

intercept; only intercepts >=2m and >5 gram x metres are

reported

-- Samples are analysed for gold by 30g fire assay fusion with

AAS instrument finish; over-range results are reanalysed by 30g

fire assay fusion with gravimetric finish

Table 1 - Section 1: Tabakoroni Sampling Techniques and Data

CRITERIA JORC CODE EXPLANATION COMMENTARY

Sampling The samples were collected from

techniques * Nature and quality of sampling (e.g. cut channels, reverse

random chips, or specific specialised industry circulation (RC) drill holes.

standard measurement tools appropriate to the RC samples were collected on 1m

minerals under investigation, such as down hole gamma intervals

sondes, or handheld XRF instruments, etc.). These by riffle split (dry) or by scoop

examples should not be taken as limiting the broad (wet), to obtain a 1-3kg sample

meaning of sampling. which

was sent to the laboratory for

crushing,

* Include reference to measures taken to ensure sample splitting and pulverising to

representivity and the appropriate calibration of any provide

measurement tools or systems used. a 30g charge for analysis.

Sampling and sample preparation

protocols

* Aspects of the determination of mineralisation that are industry standard and are

are Material to the Public Report. deemed

appropriate by the Competent

Person.

* In cases where 'industry standard' work has been done

this would be relatively simple (e.g. 'reverse

circulation drilling was used to obtain 1 m samples

from which 3 kg was pulverised to produce a 30 g

charge for fire assay'). In other cases, more

explanation may be required, such as where there is

coarse gold that has inherent sampling problems.

Unusual commodities or mineralisation types (e.g.

submarine nodules) may warrant disclosure of detailed

information.

------------------------------------------------------------ ------------------------------------

Drilling Drill types used include reverse

techniques * Drill type (e.g. core, reverse circulation, open-hole circulation.

hammer, rotary air blast, auger, Bangka, sonic, etc.)

and details (e.g. core diameter, triple or standard

tube, depth of diamond tails, face-sampling bit or

other type, whether core is oriented and if so, by

what method, etc.).

------------------------------------------------------------ ------------------------------------

Drill sample Appropriate measures are taken to

recovery * Method of recording and assessing core and chip maximise sample recovery and ensure

sample recoveries and results assessed. the representative nature of the

samples.

No apparent relationship is noted

* Measures taken to maximise sample recovery and ensure between sample recovery and grade.

representative nature of the samples.

* Whether a relationship exists between sample recovery

and grade and whether sample bias may have occurred

due to preferential loss/gain of fine/coarse

material.

------------------------------------------------------------ ------------------------------------

Logging Drill holes were geologically

* Whether core and chip samples have been geologically logged

and geotechnically logged to a level of detail to by geologists for colour,

support appropriate Mineral Resource estimation, grainsize,

mining studies and metallurgical studies. lithology, minerals, alteration and

weathering on geologically-domained

intervals.

* Whether logging is qualitative or quantitative in Holes were logged in their entirety

nature. Core (or costean, channel, etc.) photography. (100%) and this logging was

considered

reliable and appropriate.

* The total length and percentage of the relevant

intersections logged.

------------------------------------------------------------ ------------------------------------

Sub-sampling Reverse circulation samples were

techniques * If core, whether cut or sawn and whether quarter, collected

and sample half or all core taken. on 1m intervals by riffle split

preparation (dry)

or by scoop (wet) to obtain a 1-3kg

* If non-core, whether riffled, tube sampled, rotary sample.

split, etc. and whether sampled wet or dry. Sample preparation includes oven

drying,

crushing to 10mm, splitting and

* For all sample types, the nature, quality and pulverising

appropriateness of the sample preparation technique. to 85% passing -75um. These

preparation

techniques are deemed to be

* Quality control procedures adopted for all appropriate

sub-sampling stages to maximise representivity of to the material being sampled.

samples. Reverse circulation field

duplicates

were collected by the company at a

* Measures taken to ensure that the sampling is rate of 1:20 samples.

representative of the in-situ material collected, Sampling, sample preparation and

including for instance results for field quality

duplicate/second-half sampling. control protocols are of industry

standard and all attempts were made

to ensure an unbiased

* Whether sample sizes are appropriate to the grain representative

size of the material being sampled. sample was collected. The methods

applied in this process were deemed

appropriate by the Competent

Person.

------------------------------------------------------------ ------------------------------------

Quality All samples were dispatched to ALS

of assay * The nature, quality and appropriateness of the Bamako for gold analysis by 30g

data and assaying and laboratory procedures used and whether fire

laboratory the technique is considered partial or total. assay fusion with AAS instrument

tests finish

(method code Au-AA25). Over-range

* For geophysical tools, spectrometers, handheld XRF results were re-analysed and

instruments, etc., the parameters used in determining reported

the analysis including instrument make and model, by 30g fire assay fusion with

reading times, calibrations factors applied and their gravimetric

derivation, etc. finish (method code Au-GRA21). The

analytical method was appropriate

for the style of mineralisation.

* Nature of quality control procedures adopted (e.g. No geophysical tools were used to

standards, blanks, duplicates, external laboratory determine elemental concentrations.

checks) and whether acceptable levels of accuracy Quality control (QC) procedures

(i.e. lack of bias) and precision have been included

established. the use of certified standards

(1:40),

non-certified sand blanks (1:40)

and

reverse circulation field

duplicates

(1:20).

Laboratory quality control data,

including

laboratory standards, blanks,

duplicates,

repeats, grind size results and

sample

weights were also captured into the

digital database.

Analysis of the QC sample assay

results

indicates that an acceptable level

of accuracy and precision has been

achieved.

------------------------------------------------------------ ------------------------------------

Verification Verification of significant

of sampling * The verification of significant intersections by intersections

and assaying either independent or alternative company personnel. have been completed by company

personnel

and the Competent Person.

* The use of twinned holes. No drill holes within the resource

area were twinned.

Drill holes were logged into

* Documentation of primary data, data entry procedures, digital

data verification, data storage (physical and templates with lookup codes,

electronic) protocols. validated

and then compiled into a relational

SQL 2012 database using DataShed

* Discuss any adjustment to assay data. data

management software. The database

has verification protocols which

are

used to validate the data entry.

The

drill hole database is backed up on

a daily basis to the head office

server.

Assay result files were reported by

the laboratory in PDF and CSV

format

and imported into the SQL database

without adjustment or modification.

------------------------------------------------------------ ------------------------------------

Location Collar coordinates were picked up

of data * Accuracy and quality of surveys used to locate drill in UTM (WGS84) by staff surveyors

points holes (collar and down-hole surveys), trenches, mine using an RTK DGPS with an expected

workings and other locations used in Mineral Resource accuracy of +/- 0.05m; elevations

estimation. were height above EGM96 geoid.

Down hole surveys were collected at

10m intervals using a Reflex

* Specification of the grid system used. EZ-Gyro

north seeking instrument.

Coordinates and azimuths are

* Quality and adequacy of topographic control. reported

in UTM WGS84 Zone 29 North.

Tabakoroni drill holes were

translated

to local mine grid coordinates

using

1 point and rotation.

Local topographic control is via

LIDAR

surveys, satellite photography and

drone UAV aerial survey.

------------------------------------------------------------ ------------------------------------

Data spacing Drill hole spacing was sufficient

and distribution * Data spacing for reporting of Exploration Results. to demonstrate geological and grade

continuity appropriate for a

Mineral

* Whether the data-spacing and distribution is Resource and the classifications

sufficient to establish the degree of geological and applied

grade continuity appropriate for the Mineral Resource under the 2012 JORC Code.

and Ore Reserve estimation procedure(s) and The appropriateness of the drill

classifications applied. spacing

was reviewed by the geological

technical

* Whether sample compositing has been applied. team, both on site and head office.

This was also reviewed by the

Competent

Person.

Samples were collected on 1m

intervals;

no sample compositing is applied

during

sampling.

------------------------------------------------------------ ------------------------------------

Orientation Holes were drilled predominantly

of data * Whether the orientation of sampling achieves unbiased perpendicular

in relation sampling of possible structures and the extent to to mineralised domains where

to geological which this is known, considering the deposit type. possible.

structure No orientation-based sampling bias

has been identified in the data.

* If the relationship between the drilling orientation

and the orientation of key mineralised structures is

considered to have introduced a sampling bias, this

should be assessed and reported if material.

------------------------------------------------------------ ------------------------------------

Sample Samples were collected from the

security * The measures taken to ensure sample security. drill

site and stored on site. All

samples

were individually bagged and

labelled

with unique sample identifiers,

then

securely dispatched to the

laboratories.

All aspects of sampling and

dispatch

process were supervised and tracked

by SOMIFI personnel.

------------------------------------------------------------ ------------------------------------

Audits External audits of procedures

or reviews * The results of any audits or reviews of sampling indicate

techniques and data. protocols are within industry

standards.

------------------------------------------------------------ ------------------------------------

Section 2 Reporting of Exploration Results

CRITERIA JORC CODE EXPLANATION COMMENTARY

Mineral Drilling at Syama was conducted within

tenement * Type, reference name/number, location and ownership the Malian Exploitation Concession

and land including agreements or material issues with third Permit PE 93/003 which covers an area

tenure parties such as joint ventures, partnerships, of 200.6 Km2.

status overriding royalties, native title interests, Resolute Mining Limited has an 80%

historical sites, wilderness or national park and interest in the Syama project and

environmental settings. the Exploitation Permit PE 93/003,

on which it is based, through its

Malian subsidiary, Société

* The security of the tenure held at the time of des Mines de Syama SA (SOMISY). The

reporting along with any known impediments to Malian Government holds a free carried

obtaining a licence to operate in the area. 20% interest in SOMISY.

Tabakoroni drilling was completed

within the Finkolo-Tabakoroni Exploitation

Licence PE 13/19. Resolute Mining

Limited has an 85% interest in Exploitation

Permit PE 13/19, through its Malian

subsidiary, Société des

Mines de Finkolo SA (SOMIFI). The

Malian Government holds a free carried

10% interest in SOMIFI and a free

carried 5% interest is held privately.

The Permits are held in good standing.

Malian mining law provides that all

Mineral Resources are administered

by DNGM (Direction Nationale de la

Géologie et des Mines) or National

Directorate of Geology and Mines under

the Ministry of Mines, Energy and

Hydrology.

--------------------------------------------------------------- ------------------------------------------------------------

Exploration The Syama deposit was originally discovered

done by * Acknowledgment and appraisal of exploration by other by a regional geochemical survey undertaken

other parties. by the Direction National de Géologie

parties et des Mines (DNGM) with assistance

from the United Nations Development

Program (UNDP) in 1985. There had

also been a long history of artisanal

activities on the hill where an outcropping

chert horizon originally marked the

present day position of the open pit.

BHP during 1987-1996 sampled pits,

trenches, auger, RC and diamond drill

holes across Syama prospects. Randgold

Resources Ltd during 1996-2000 sampled

pits, trenches, auger, RAB, RC and

diamond drill holes across Syama prospects.

Etruscan Resources Inc explored Tabakoroni

during 2002-2003 by auger, aircore,

RC and diamond drill hole tails. The

Tabakoroni area was previously explored

Barrick Gold (1990) by auger, pits,

trenches, RAB and diamond core drilling.

--------------------------------------------------------------- ------------------------------------------------------------

Geology The Syama Project is found on the

* Deposit type, geological setting and style of northern margin of the Achaean-Proterozoic

mineralisation. Leo Shield which forms the southern

half of the West African Craton. The

project area straddles the boundary

between the Kadiana-Madinani terrane

and the Kadiolo terrane. The Kadiana-Madinani

terrane is dominated by greywackes

and a narrow belt of interbedded basalt

and argillite. The Kadiolo terrane

comprises polymictic conglomerate

and sandstone that were sourced from

the Kadiana-Madinani terrane and deposited

in a late- to syntectonic basin.

Prospects are centred on the NNE striking,

west dipping, Syama-Bananso Fault

Zone and Birimian volcano-sedimentary

units of the Syama Formation. The

major commodity being sought is gold.

The Tabakoroni deposit is hosted in

upright tightly folded greenstone

rocks of the Syama Formation, comprising

interbedded basalt and sediment units,

and an overlying complex sequence

of deep marine and turbiditic sediments.

The sequence overlying the basalts

contains interbedded carbonaceous

units (silts and shales) that are

preferentially deformed, and which

form the Tabakoroni Main Shear Zone

(TMSZ) that lies along the approximate

contact of the greenstone-sediment

sequence. Gold mineralisation occurs

within the TMSZ associated with quartz

vein stockworks and stylolitic quartz

reefs.

--------------------------------------------------------------- ------------------------------------------------------------

All information, including easting,

Drill * A summary of all information material to the northing, elevation, dip, azimuth,

hole understanding of the exploration results including a coordinate system, drill hole length,

Information tabulation of the following information for all intercept length and depth are measured

Material drill holes: and recorded in UTM Zone 29 WGS84.

The Syama belt is mostly located on

the Tengrela 1/200,000 topo sheet

o easting and northing of the (Sheet NC 29-XVIII).

drill hole collar The Tabakoroni local grid has been

o elevation or RL (Reduced tied to the UTM Zone 29 WGS84 co-ordinate

Level - elevation above sea system.

level in metres) of the drill Spectrum Survey & Mapping from Australia

hole collar established survey control at Tabakoroni

o dip and azimuth of the hole using AusPos online processing to

o down hole length and interception obtain an accurate UTM Zone 29 (WGS84)

depth and 'above geoid' RL for the origin

o whole length. of the survey control points.

* If the exclusion of this information is justified on Accuracy of the survey measurements

the basis that the information is not Material and is considered to meet acceptable industry

this exclusion does not detract from the standards.

understanding of the report, the Competent Person Drill hole information has been tabulated

should clearly explain why this is the case. for this release in the intercepts

table of the accompanying text.

For completeness the following information

about the drill holes is provided:

* Easting, Northing and RL of the drill hole collars

are measured and recorded in UTM Zone 29 (WGS84)

* Dip is the inclination of the drill hole from

horizontal. A drill hole drilled at -60deg is 60deg

from the horizontal

* Down hole length is the distance down the inclination

of the hole and is measured as the distance from the

horizontal to end of hole

* Intercept depth is the distance from the start of the

hole down the inclination of the hole to the depth of

interest or assayed interval of interest.

--------------------------------------------------------------- ------------------------------------------------------------

Data Exploration results reported in this

aggregation * In reporting Exploration Results, weighting averaging announcement are tabulated using the

methods techniques, maximum and/or minimum grade truncations following parameters:

(e.g. cutting of high grades) and cut-off grades are * Grid coordinates are WGS84 Zone 29 North

usually Material and should be stated.

* Cut-off grade for reporting of intercepts is >=1g/t

* Where aggregate intercepts incorporate short lengths Au

of high-grade results and longer lengths of low-grade

results, the procedure used for such aggregation

should be stated and some typical examples of such * No top cut of individual assays prior to length

aggregations should be shown in detail. weighted compositing of the reported intercept has

been applied

* The assumptions used for any reporting of metal

equivalent values should be clearly stated. * Maximum 3m consecutive internal dilution included

within the intercept

Metal equivalent values are not used

in reporting.

--------------------------------------------------------------- ------------------------------------------------------------

Relationship The Syama mineralisation is steeply

between * These relationships are particularly important in the dipping at approximately 60 degrees

mineralisation reporting of Exploration Results. from the horizontal.

widths The majority of the Tabakoroni mineralisation

and intercept is vertical. There is one domain which

lengths * If the geometry of the mineralisation with respect to dips at 45o to the west.

the drill hole angle is known, its nature should be The majority of the drill holes are

reported. planned at a general inclination of

--60 degrees east and as close to

perpendicular to the ore zone as possible.

* If it is not known and only the down hole lengths are At the angle of the drill holes and

reported, there should be a clear statement to this the dip of the ore zones, the reported

effect (e.g. 'down hole length, true width not intercepts will be slightly more than

known'). true width.

--------------------------------------------------------------- ------------------------------------------------------------

Diagrams Relevant maps, diagrams and tabulations

* Appropriate maps and sections (with scales) and are included in the body of text.

tabulations of intercepts should be included for any

significant discovery being reported These should

include, but not be limited to a plan view of drill

hole collar locations and appropriate sectional

views.

--------------------------------------------------------------- ------------------------------------------------------------

Balanced Exploration results and infill drilling

reporting * Where comprehensive reporting of all Exploration results are being reported in this

Results is not practicable, representative reporting announcement and tabulated in the

of both low and high grades and/or widths should be body of the text.

practiced, to avoid misleading reporting of

Exploration Results.

--------------------------------------------------------------- ------------------------------------------------------------

Other No geophysical and geochemical data

substantive * Other exploration data, if meaningful and material, or any additional exploration information

exploration should be reported including (but not limited to): has been reported in this release,

data geological observations; geophysical survey results; as they are not deemed relevant to

geochemical survey results; bulk samples - size and the release.

method of treatment; metallurgical test results; bulk

density, groundwater, geotechnical and rock

characteristics; potential deleterious or

contaminating substances.

--------------------------------------------------------------- ------------------------------------------------------------

Further Further drilling is planned.

work * The nature and scale of planned further work (e.g.

tests for lateral extensions or depth extensions or

large-scale step-out drilling).

* Diagrams clearly highlighting the areas of possible

extensions, including the main geological

interpretations and future drilling areas, provided

this information is not commercially sensitive.

--------------------------------------------------------------- ------------------------------------------------------------

Section 3 Estimation and Reporting of Mineral Resources

CRIT ERIA JORC CODE E XP L A N A T I ON CO M M ENT ARY

Database Data have been compiled into a

integrity * Measures taken to ensure that data has not been relational SQL database;

corrupted by, for example, transcription or keying the setup of this database

errors, between its initial collection and its use precludes the loading of data

for Mineral Resource estimation purposes. which do not meet the required

validation protocols. The

data is managed using DataShed(c)

* Data validation procedures used. drill hole management

software using SQL database

techniques. Validation checks

are conducted using SQL and

DataShed(c) relational database

standards. Data has also been

checked against original hard

copies for 100% of the data, and

where possible, loaded

from original data sources.

Resolute completed the following

basic validation checks

on the data supplied prior to

resource estimation:

Drill holes with overlapping sample

intervals

Sample intervals with no assay data

or duplicate records

Assay grade ranges

Collar coordinate ranges

Valid hole orientation data.

There are no significant issues

identified with the data.

------------------------------------------------------------- -----------------------------------

Site visits Mrs Susan Havlin, an employee of

* Comment on any site visits undertaken by the Optiro and a Member of

Competent Person and the outcome of those visits. the Australasian Institute of

Mining and Metallurgy is the

Competent Person who has visited

* If no site visits have been undertaken indicate why this site in February and

this is the case. October 2019.

All aspects of drilling, sampling

and mining are considered

by the Competent Persons to be of a

high industry standard.

------------------------------------------------------------- -----------------------------------

Geological The digital database used for the

interpretation * Confidence in (or conversely, the uncertainty of) the interpretation included

geological interpretation of the mineral deposit. logged intervals for the key

stratigraphic zones of Tabakoroni.

Detailed geological logs were

* Nature of the data used and of any assumptions made. available in hardcopy and

digital and reviewed where

necessary.

* The effect, if any, of alternative interpretations on There is a high level of confidence

Mineral Resource estimation. for the interpretation

of the Tabakoroni Main Shear Zone

(TMSZ) due to the close-spaced

* The use of geology in guiding and controlling Mineral grade control drilling at surface

Resource estimation. and the confirmation of

the position in the current oxide

pits. Since an independent

* The factors affecting continuity both of grade and structural model was created there

geology. is high level of confidence

in the geological interpretation of

the minor lodes adjacent

to the TMSZ.

Wireframes used to constrain the

estimation are based on

drill hole intercepts and

geological boundaries. All

wireframes

at Tabakoroni have been constructed

to a 1g/t Au cut-off

grade for shape consistency.

The mineralisation in the TMSZ is

generally quite consistent

and drill intercepts clearly define

the shape of the mineralised

zones with limited options for

large scale alternate

interpretations.

------------------------------------------------------------- -----------------------------------

Dimensions The mineral resource at Tabakoroni

* The extent and variability of the Mineral Resource comprises four individual

expressed as length (along strike or otherwise), plan domains. The main zone is the TMSZ,

width, and depth below surface to the upper and lower which extends for approximately

limits of the Mineral Resource. 1,800 metres along strike; the

sub-vertical dipping gold

mineralised zone width varies

between 1.5 and 15 metres,

with an average thickness of 5

metres. The Mineral Resource

is limited in depth by drilling,

which extends from surface

to a maximum depth of approximately

450 metres vertically.

There is a zone parallel to the

TMSZ which is generally

at depth and not as consistent;

this is dominantly in the

central part of the deposit. The

northeast (NE) domain is

a zone which is striking at 20deg

and is sub vertical in

the north of the deposit. The

southern lode is shallow

westerly-dipping

lodes in the southern and central

portion of the deposit.

The whole of the Tabakoroni

deposit, including domains

additional

to the TMSZ, extends for 450 metres

in the horizontal plane.

------------------------------------------------------------- -----------------------------------

Estimation Estimation was completed in

and modelling * The nature and appropriateness of the estimation Datamine Studio RM using an

techniques technique(s) applied and key assumptions, including Ordinary Kriged model to estimate

treatment of extreme grade values, domaining, the gold grade. Grades

interpolation parameters and maximum distance of were estimated into parent block of

extrapolation from data points. If a computer 5 mE by 10 mN by 5 mRL

assisted estimation method was chosen include a with sub- celling down to 1mE by 2

description of computer software and parameters used. mN by 1 mRL was employed

for resolution of the

mineralisation boundaries as

* The availability of check estimates, previous defined

estimates and/or mine production records and whether by wireframes. The drill spacing at

the Mineral Resource estimate takes appropriate Tabakoroni varies from

account of such data. 12.5 by 12.5 metres for grade

control to between 25 and

50 metres for the exploration

* The assumptions made regarding recovery of by- holes.

products. Drillhole sample data was flagged

using domain codes generated

from three-dimensional

* Estimation of deleterious elements or other non-grade mineralisation domains. The grade

variables of economic significance (e.g. sulphur for control samples and exploration

acid mine drainage characterization). samples were composited

to 1 metre intervals.

Variogram orientations were largely

* In the case of block model interpolation, the block controlled by the strike

size in relation to the average sample spacing and of the mineralisation and downhole

the search employed. variography. Variograms

for estimation purposes were

determined for each domain.

* In the case of block model interpolation, the block Kriging neighbourhood analysis was

size in relation to the average sample spacing and performed to optimise

the search employed. the block size, sample numbers and

discretisation levels

with the goal of minimising

* Any assumptions behind modelling of selective mining conditional bias in the gold

units. grade estimates.

Mineralisation domains were treated

as hard boundaries in

* Any assumptions about correlation between variables. the estimation process while

oxidation surfaces were treated

as soft boundaries.

* Description of how the geological interpretation was Three search passes were used, with

used to control the resource estimates. the first search pass

set to the range of the variogram

for each element. A minimum

* Discussion of basis for using or not using grade of 8 and a maximum of 30 samples

cutting or capping. were used. The search stayed

the same for the second pass but

was increased by a factor

* The process of validation, the checking process used, of 2 for the third and final pass.

the comparison of model data to drill hole data, and The minimum number of

use of reconciliation data if available. samples was reduced to 6 for the

second pass and 4 for the

third pass.

No deleterious elements were found

in the ore.

No selective mining units have been

assumed.

Top cuts were applied to reduce the

variability of the data

and to remove the outliers.

The estimated block model grades

were visually validated

against the input drillhole data

and comparisons were carried

out against the drillhole data and

by northing and elevation

slices. Global comparison between

the input data and the

block grades for each variable is

considered acceptable

(+/-10%).

Comparison with the mine production

to date was carried

out and was within an acceptable

limit.

------------------------------------------------------------- -----------------------------------

Moisture All tonnages have been estimated on

* Whether the tonnages are estimated on a dry basis or a dry basis.

with natural moisture, and the method of

determination of the moisture content.

------------------------------------------------------------- -----------------------------------

Cut-off parameters Mineral Resources for open pit

* The basis of the adopted cut-off grade(s) or quality extraction have been reported

parameters applied. at a 1 g/t Au grade cut-off and

above a US$2000/oz optimised

shell. The Mineral Resources for

underground mining are

undiluted and the mineralised

blocks (within the mineralisation

wireframes) have been reported

within MSO wireframes created

at US$2,000/oz which is equivalent

to 1.75 g/t Au cut-off

grade.

------------------------------------------------------------- -----------------------------------

Mining factors A Pre-Feasibility study determined

or assumptions * Assumptions made regarding possible mining methods, the mining method would

minimum mining dimensions and internal (or, if be by long hole open stoping. No

applicable, external) mining dilution. It is always Mineral Resource margin

necessary as part of the process of determining (external) dilution has been

reasonable prospects for eventual economic extraction modelled. A minimum stope dip

to consider potential mining methods, but the of 30 degrees on the footwall was

assumptions made regarding mining methods and applied. More rigorous

parameters when estimating Mineral Resources may not mining assumptions and parameters

always be rigorous. Where this is the case, this will be applied during

should be reported with an explanation of the basis the conversion to Ore Reserves.

of the mining assumptions made.

------------------------------------------------------------- -----------------------------------

Metallurgical No metallurgical factors or

factors or * The basis for assumptions or predictions regarding assumptions have been made during

assumptions metallurgical amenability. It is always necessary as the resource estimation process as

part of the process of determining reasonable these will be addressed

prospects for eventual economic extraction to during the conversion to Ore

consider potential metallurgical methods, but the Reserves.

assumptions regarding metallurgical treatment

processes and parameters made when reporting Mineral

Resources may not always be rigorous. Where this is

the case, this should be reported with an explanation

of the basis of the metallurgical assumptions made.

------------------------------------------------------------- -----------------------------------

Environmental It is a requirement of Decree

factors or * Assumptions made regarding possible waste and process No.03-594/P-RM of 31 December

assumptions residue disposal options. It is always necessary as 2003 of Malian law that an

part of the process of determining reasonable Environmental and Social Impact

prospects for eventual economic extraction to Study (Étude d'Impact

consider the potential environmental impacts of the Environmental et Social - EIES)

mining and processing operation. While at this stage must be undertaken to update the

the determination of potential environmental impacts, potential environmental

particularly for a green fields project, may not and social impacts of the mine's

always be well advanced, the status of early redevelopment. The EIES

consideration of these potential environmental for the Syama Gold Mine (including

impacts should be reported. Where these aspects have Tabakoroni) was approved

not been considered this should be reported with an in November 2007 and an Environment

explanation of the environmental assumptions made. Permit (07- 0054/MEA

- SG) was issued by the Ministry of

Environment and Sanitation

on 22 November 2007. The Ministry

of Environment conducts

timely reviews of the Syama Gold

Mine to ensure that company

maintains compliance with the EIES

guidelines.

At Syama and Tabakoroni, there are

three key practices for

disposal of wastes and residues

namely, stacking of waste

rock from open pit mining; storage

of tailings from mineral

processes; and "tall-stack

dispersion" of sulphur dioxide

from the roasting of gold bearing

concentrate. All waste

disposal practices are in

accordance with the guidelines

in the EIES.

The Environmental & Social Impact

Study - "Société

des Mines de Syama, Syama Gold

Mine, Mali", dated 2007 indicated

there was minimal potential for

acid mine drainage from

waste rock due to the elevated

carbonate content which buffers

a potential acid generation.

Resolute maintains a plan for

progressive rehabilitation of waste

rock landforms as part

of ongoing mine development and

waste rock dumping.

The landform of tailings

impoundments does not have a net

acid generating potential. The

largest volume is flotation

tailings where the sulphide

minerals have already been removed

from the host rock. Its mineralogy

includes carbonates which

further buffer any acid-formation

potential from sulphides

that may also be present.

Cyanide levels in the

leached-calcine tailings are

typically

less than 50 ppm in the weak acid

dissociable form. Groundwater

away from the tailings landform is

intercepted by trenches

and sump pumps.

Sulphur dioxide is generated from

the roasting of gold concentrate

so that gold can be extracted and

refined. Tall-Stack "dispersion"

of the sulphur dioxide emission is

monitored continuously.

Prevailing weather and dissipation

of the sulphur dioxide

is modelled daily to predict the

need to pause the roasting

process to meet the air quality

criteria set out in the

Environmental & Social Impact

Study.

------------------------------------------------------------- -----------------------------------

Bulk density Site personnel have completed

* Whether assumed or determined. If assumed, the basis numerous bulk density comparative

for the assumptions. If determined, the method used, estimates on HQ drill core to

whether wet or dry, the frequency of the measurements assess variability using the

, Archimedes method of dry weight

the nature, size and representativeness of the versus weight in water.

samples. This method was used for 71% of the

bulk density measurements.

The other 29% is by unknown method.

* The bulk density for bulk material must have been On the basis of the data collected

measured by methods that adequately account for void the following SG estimates

spaces (vugs, porosity, etc), moisture and were applied to the model by

differences between rock and alteration zones within weathering type:

the deposit.

Oxide 2.12 t/m3

Transitional 2.38 t/m3

* Discuss assumptions for bulk density estimates used Fresh 2.72 t/m3

in the evaluation process of the different materials.

------------------------------------------------------------- -----------------------------------

Classification The Measured Mineral Resource

* The basis for the classification of the Mineral classification is based on

Resources into varying confidence categories. good confidence in the geology and

gold grade continuity

with 12.5 m x 12.5 m spaced

* Whether appropriate account has been taken of all drillhole density in the central

relevant factors (i.e. relative confidence in part of the deposit.

tonnage/grade estimations, reliability of input data, The Indicated Mineral Resource

confidence in continuity of geology and metal values, classification is based on

quality, quantity and distribution of the data). good confidence in the geology and

gold grade continuity

with less than 50 m x 50 m spaced

* Whether the result appropriately reflects the drillhole density in the

Competent Person's view of the deposit. central part of the deposit.

The Inferred Mineral Resource

classification is applied

to extensions of mineralised zones

on the margins of the

deposit where drill spacing is more

than 50 m x 50 m and

the extents of mineralisation at

depth.

The validation of the block model

has confirmed satisfactory

correlation of the input data to

the estimated grades and

reproduction of data trends.

The Mineral Resource estimate

appropriately reflects the

view of the Competent Persons.

------------------------------------------------------------- -----------------------------------

Audits or The Mineral Resource has been

reviews * The results of any audits or reviews of Mineral audited internally and in

Resource estimates. conjunction with resource

consultants at Optiro as part

of the routine validation process.

There has been no external

review of the Mineral Resource

estimate.

------------------------------------------------------------- -----------------------------------

Discussion The relative accuracy of the

of relative * Where appropriate a statement of the relative Mineral Resource estimate is

accuracy/ accuracy and confidence level in the Mineral Resource reflected in the reporting of

confidence estimate using an approach or procedure deemed Measured, Indicated and Inferred

appropriate by the Competent Person. For example, the resource categories as defined by

application of statistical or geostatistical 2012 JORC Code guidelines.

procedures to quantify the relative accuracy of the The estimate is considered to be

resource within stated confidence limits, or, if such relevant to an annual level

an approach is not deemed appropriate, a qualitative of reporting of tonnage and grade.

discussion of the factors that could affect the The estimation was compared with

relative accuracy and confidence of the estimate. the production history

at Tabakoroni and it is within 15%

which is within the limits

* The statement should specify whether it relates to for the relevant classifications.

global or local estimates, and, if local, state the

relevant tonnages, which should be relevant to

technical and economic evaluation. Documentation

should include assumptions made and the procedures

used.

* These statements of relative accuracy and confidence

of the estimate should be compared with production

data, where available.

------------------------------------------------------------- -----------------------------------

This information is provided by RNS, the news service of the

London Stock Exchange. RNS is approved by the Financial Conduct

Authority to act as a Primary Information Provider in the United

Kingdom. Terms and conditions relating to the use and distribution

of this information may apply. For further information, please

contact rns@lseg.com or visit www.rns.com.

RNS may use your IP address to confirm compliance with the terms

and conditions, to analyse how you engage with the information

contained in this communication, and to share such analysis on an

anonymised basis with others as part of our commercial services.

For further information about how RNS and the London Stock Exchange

use the personal data you provide us, please see our Privacy

Policy.

END

DRLZDLBLFFLEBBL

(END) Dow Jones Newswires

January 27, 2021 02:00 ET (07:00 GMT)

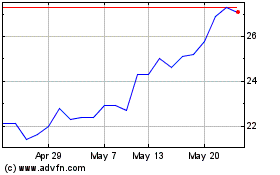

Resolute Mining (LSE:RSG)

Historical Stock Chart

From Jan 2025 to Feb 2025

Resolute Mining (LSE:RSG)

Historical Stock Chart

From Feb 2024 to Feb 2025