In the quest for sustainable energy solutions, hydrogen has emerged as a frontrunner, promising a cleaner, greener future. Leading this transition is Lorentz, with its pioneering hydrogen production method poised to revolutionise the energy landscape.

Lorentz’s revolutionising hydrogen production

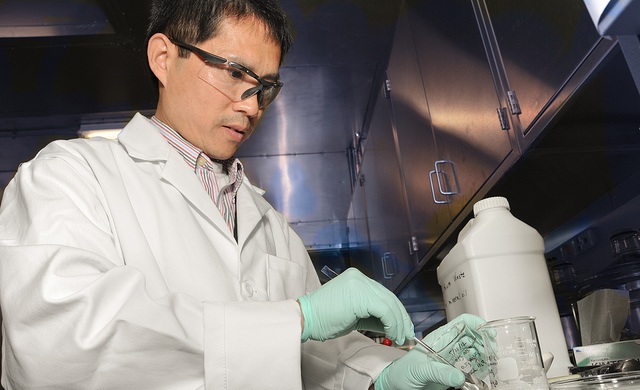

The innovative approach to hydrogen production originates from a technology patented in 1974 by Anders Olsson. Whilst developing a different innovation, Olsson discovered a method that produced hydrogen as a by-product. Hydrogen’s potential was overlooked at the time, but 50 years later, a surge in demand has led to further technological advancements. Lorentz, in response, has refined its proprietary technology to achieve enhanced efficiency.

Atomic simplicity: the abundance of hydrogen

Hydrogen, the simplest and most abundant element in the universe, makes up about 75% of the elemental mass in the universe. It can be extracted from water, hydrocarbons, and other sources, and can be stored in either gas or liquid form, the latter requiring cooling to -253 degrees Celsius.

Government support fuels the adoption of clean hydrogen

Today, hydrogen is recognized as key to decarbonizing heavy industries spanning agriculture, transportation, and aviation. Its applications extend to petroleum refining, methanol production, and ammonia manufacturing. Replacing coal with hydrogen in steel production alone could save approximately 1.5 metric tons of carbon dioxide emissions per ton of steel.

This increasing focus on green hydrogen has attracted interest from investors, driven by its potential to address future energy demands while curbing carbon emissions.

The hydrogen industry is also receiving a boost from governmental initiatives. In 2023, the U.S. Department of Energy emphasised the crucial role of clean hydrogen in achieving carbon neutrality by 2050. Meanwhile, the European Union has mandated that at least 1.2% of aviation fuel must come from green hydrogen by 2030, with a goal of 35% by 2050.

Hydrogen’s high energy content adds to its appeal as an energy source. One kilogram of hydrogen has 2.6 to 3.4 times more energy than one kilogram of petroleum, depending on the type of petroleum and the source of hydrogen.

- Traditional methods of hydrogen production, notably extraction from natural gas, carry a significant carbon footprint.

- Standard green hydrogen production through electrolysis, require more than 39.4 kWh to produce 1kg hydrogen gas and generates 5.5kg of carbon dioxide.

- The Lorentz method needs only a fraction of the above-mentioned energy and emits zero carbon dioxide. The process only requires water and energy, which can be produced by solar power. The energy, aided by a catalytic effect, splits the water into hydrogen and oxygen gas. The low energy requirement makes the Lorentz solution an environmentally and economically superior solution.

Transforming the energy sector: Lorentz’s unique approach

Lorentz, established in 2023, is playing a significant role in decarbonizing the energy sector. The company specialises in green hydrogen production and plans to launch its first project in Spain, with a solar-powered demonstration unit. This technology uses a proprietary catalytic process designed to produce green hydrogen in an environmentally friendly and cost-effective way.

Fuel cells powered by hydrogen are already transforming transportation, with trucks that emit only water vapor and can drive up to 1,000 km without refuelling. Companies like Volvo are already testing these trucks, pointing toward a future where hydrogen-powered vehicles become mainstream.

For instance, imagine a car journey from London, England to Rome, Italy. This distance is approximately 1760 km (1100 miles) and the fuel cost for a regular Diesel or Petrol car would be around €290, whilst emitting about 422 kg of CO2. An EV consumes approximately 264 kWh, at a cost of approximately €175 to travel the same distance, emitting 132 kg of CO2 (assuming the electricity if produced from natural gas).

A hydrogen fuelled car emits only water and the same journey would cost just €17 if the car was fuelled with Lorentz hydrogen gas (production cost). The Lorentz method is cost effective due to cutting out the transport element as well as the innovative process itself. The entire journey emits just 157 kg H2O.

Despite its potential, green hydrogen still faces challenges, such as safety concerns, high costs, infrastructure limitations, and ensuring that renewable energy sources are used in its production.

The implications are profound, with Lorentz’s method offering a scalable, economically viable solution to meet the burgeoning demand for hydrogen. As governments worldwide commit to carbon neutrality targets and renewable energy mandates, Lorentz’s innovation emerges as a viable alternative in the transition towards a cleaner, more sustainable energy future.

Lorentz’s strategy: zero-emission hydrogen-production, zero transport factor

Lorentz’s catalytic process is designed to produce zero-emission hydrogen with minimal energy consumption. This innovation not only makes green hydrogen production more affordable but also eliminates the need for costly and potentially hazardous transportation. With the Lorentz method, the hydrogen gas is produced where it’s needed, using only 8.94 litres of water per kilogram of hydrogen and electricity that can be generated from the sun.

Expanding infrastructure with strategic partnerships

Imagine a future where hydrogen-powered vehicles can refuel seamlessly at any petrol station equipped with Lorentz’s compact hydrogen refill stations, powered solely by solar energy and water. Lorentz’s modular technology allows hydrogen refuelling stations to be installed quickly at existing petrol stations, facilitating the expansion of hydrogen infrastructure. This rapid rollout can help overcome one of the main barriers to adopting renewable energy sources.

The founder, Anders Olsson, has partnered with Nexergy Holdings PLC a key investor, to drive the green hydrogen market and position Lorentz as a leader in renewable energy. Their strategy focuses on localised hydrogen production, aligning with the broader goal of a sustainable energy transition.

As investments in new technologies increase, the appeal of adopting energy-efficient solutions grows ever stronger. The successful generation of clean and affordable energy from green hydrogen necessitates the deployment of technologies and collaborative initiatives.

Hot Features

Hot Features