Metals Acquisition Limited (NYSE: MTAL) (ASX:MAC):

This press release features multimedia. View

the full release here:

https://www.businesswire.com/news/home/20240319036286/en/

Figure 1 – CSA Copper Mine Long Section

(Graphic: Business Wire)

Metals Acquisition Limited (“MAC” or the “Company”) today

provides a market update on the continuing exploration and resource

development at the CSA Copper Mine:

Highlights

- The 2023 Resource and Reserve estimate is scheduled for release

in Q2 2024

- All results reported in this release are after the cut-off date

(August 31, 2023) for the 2023 Resource and Reserve and will be

incorporated in the subsequent Resource and Reserve Estimate

update.

- Results from QTS North (“QTSN”) include:

- 14m @ 7.9% Cu from 159m in UDD20139

- 16m @ 10.4% Cu from 102m in UDD23024

- 19.2m @10.4% Cu from 114.8m in UDD23025

- Results from QTS Central (“QTSC”) include:

- 11.5m @ 11.8% Cu from 180.5m in UDD22052

- 6.9m @ 11.3% Cu from 114.5m in UDD22040

- 25.6m @ 6.1% Cu from 152.4m in UDD22049A

- 14.5m @ 9.0% Cu from 146.5m in UDD22054

- Results from the near surface QTS South Upper A (“QTSSUA”)

include:

- 1.7m @ 21.3% Cu from 281.2m in QSDD057C

- 3.0m @ 13.9% Cu from 268.7m in QSDD059

- 4.3m @ 14.2% Zn, 3.9% Pb and 0.8% Cu from 294.4m in

QSDD060

Discussion

MAC has continued drilling since acquiring the CSA Copper Mine

in June 2023 with a view to expand it’s high quality resource base

to underpin a new reserve estimate and mine plan. Due to the lead

time required to complete a full reserve estimate and mine plan the

data cut off for the 2023 Resource and Reserve Statement is August

31,2023. All results reported in this release are after that cut

off.

Results are reported as down hole widths. A complete list of

post-August 2023 resource drilling is contained in Table 1 at the

end of this report.

MAC CEO, Mick McMullen commented “These results continue to

showcase why we think the CSA Copper Mine has a long future with

continued exploration success converting the Inferred Resource to

Measured and Indicated, together with adding new mineralisation to

the inventory. QTS North continues to demonstrate good continuity

at depth with what is in line with observed CSA Copper Mine widths

and grades such as the 19.2m @ 10.4% Cu in UDD23025.

QTS Central appears to be getting wider with the new drilling

which is very encouraging from what is already our highest margin

ore. The shallow high-grade results from QTS South Upper A are very

encouraging and work is underway in incorporating this into a

resource estimate for mine planning purposes. The presence of a

high-grade Zn lens in this area is interesting and drilling is

underway on the shallow potions of the nearby East and West lodes

to determine what mineralisation may not have been mined

historically.

Following the recent A$325m capital raise associated with the

ASX listing, the Company is accelerating its in mine and near mine

exploration efforts given that most of the ore bodies are open. The

grades at the CSA Copper Mine are high and the return on capital

from adding incremental resources adjacent to existing

infrastructure is compelling.”

CSA Copper Mine

The CSA Copper Mine is a world class mine that consists of a

series of mineralized lenses that extend from surface to a depth of

over 2.3km. The main deposits are QTSN, QTSC, QTSS, East and West

lenses with additional mineralisation in the near surface QTSS

Upper A zone. Approximately 75% of the resources are contained in

QTSN.

The resource model for QTSN commences approximately 850m below

surface, with all data above that in hard copy and not in the

digital database. Work is underway to digitize and validate this

data and will be incorporated into a future resource update. Based

on the initial information it would appear that there are

reasonable prospects for additional mineralisation in the top 850m

of the mine.

Refer to Figure 1 below for the location of the various

deposits.

Exploration Results

Figure 1 – CSA Copper Mine Long Section

Drilling has been targeting conversion of Inferred resource to

Measured and Indicated for inclusion in the Reserve Estimate, as

well as the known mineralized lenses to add incremental

resources.

The location of the significant drill results is shown in Figure

2 below.

Figure 2 – QTSN and QTSC Long Section

At QTSN, the most recent drilling has confirmed the location of

the Inferred Resource and enabled it to be upgraded as well as

confirmation of the smaller mineralized lenses adjacent to the

existing resource. This can be seen in Figure 3. QTSN is

characterised by a series of high-grade lenses (grading plus 5% Cu)

that can range in width from 10-35m surrounded by a lower grade

halo on the footwall.

As drilling has progressed down dip it would appear that tonnes

per vertical metre are increasing.

Figure 3 – QTSN Cross Section

QTSC is located adjacent to QTSN and is centred around a depth

of 1.4km and is open both up and down dip. QTSC is typically

narrower than QTSN but higher grade. As seen in Figure 4 the most

recent drilling continues to confirm the presence of the high-grade

mineralisation below the current working level through the Inferred

Resource and into mineralised material that will extend the

resource beyond its current limits.

Figure 4 – QTSC Cross Section

QTSS Upper A is a narrow (1.5 to 3m) but a high-grade zone of

mineralisation that is much shallower than the rest of the mine.

This lens starts approximately 120m below surface and extends to

approximately 350m below surface. Drilling from surface was

targeting upgrading the confidence level of the mineralization to

allow inclusion in the new 2023 Resource and Reserves Estimate and

for mine planning purposes.

This lens is narrower than the average QTSN and QTSC lenses but

share a higher grade with QTS Central. In a mine known for high

grade copper material the QTSS Upper A lens stands out based on

intercepted grades of 1.7m @ 21.3% Cu in QSDD057C and 3m @ 13.9% Cu

in QSDD059. These are truly exceptional Cu grades and even with

diluted stope shapes for mining purposes the grade from this lens

is high.

Of note also is the intercepted 4.3m @ 14.2% Zn, 3.9% Pb and

0.8% Cu in QSDD060 immediately downhole of the 0.5m @ 9.1% Cu in

the same hole. The CSA Copper Mine started life as a high-grade Zn,

Pb, and Cu mine in the upper portions of the mine and there exists

high grade Zn and Pb zones immediately in the footwall of the

higher grade Cu zones that require further investigation.

Competent and Qualified Person Statement(s)

The information in this announcement that relates to Exploration

Results at the CSA Copper Mine is based on information compiled or

reviewed by Patrick Adams, a Competent Person who is a Fellow of

the Australian Institute of Mining and Metallurgy. Mr. Adams is

employed by Cube Consulting Pty Ltd. Mr. Adams has sufficient

experience which is relevant to the style of mineralisation and

type of deposit under consideration and to the activity being

undertaken to qualify as a Competent Person as defined in the JORC

Code. Mr. Adams has given (and not withdrawn) written consent to

the inclusion in the report of the results reported here and the

form and context in which it appears. Mr. Adams is also a Qualified

Person as defined by S-K 1300 rules for mineral deposit disclosure.

Mr. Adams further consents as Qualified Person to the inclusion in

the report of the matters based on information in the form and

context in which it appears.

This announcement is authorised for release by Mick McMullen,

Chief Executive Officer and Director.

About Metals Acquisition Limited

Metals Acquisition Limited (NYSE: MTAL; ASX:MAC) is a company

focused on operating and acquiring metals and mining businesses in

high quality, stable jurisdictions that are critical in the

electrification and decarbonization of the global economy.

Cautionary and Forward Looking Statements

This press release has been prepared by Metals Acquisition

Limited (“Company” or “MAC”), has been prepared in compliance with

the JORC Code 2012 Edition and includes “forward-looking

statements.” The ‘forward-looking information’ is based on the

Company’s expectations, estimates and projections as of the date on

which the statements were made.

MAC’s actual results may differ from expectations, estimates,

and projections and, consequently, you should not rely on these

forward-looking statements as predictions of future events. Words

such as “expect,” “estimate,” “project,” “budget,” “forecast,”

“anticipate,” “intend,” “plan,” “may,” “will,” “could,” “should,”

“believes,” “predicts,” “potential,” “continue,” and similar

expressions (or the negative versions of such words or expressions)

are intended to identify such forward- looking statements. These

forward-looking statements include, without limitation, MAC’s

expectations with respect to future performance of the CSA Copper

Mine and anticipated financial impacts and other effects of the

proposed business combination, the satisfaction of the closing

conditions to the proposed transaction and the timing of the

completion of the proposed transaction. These forward-looking

statements involve significant risks and uncertainties that could

cause the actual results to differ materially from those discussed

in the forward-looking statements. Most of these factors are

outside MAC’s control and are difficult to predict. Factors that

may cause such differences include, but are not limited to: the

ability to recognize the anticipated benefits of the business

combination, which may be affected by, among other things; the

supply and demand for copper; the future price of copper; the

timing and amount of estimated future production, costs of

production, capital expenditures and requirements for additional

capital; cash flow provided by operating activities; unanticipated

reclamation expenses; claims and limitations on insurance coverage;

the uncertainty in mineral resource estimates; the uncertainty in

geological, metallurgical and geotechnical studies and opinions;

infrastructure risks; and dependence on key management personnel

and executive officers; and other risks and uncertainties indicated

from time to time in the definitive proxy statement/prospectus

relating to the business combination that MAC filed with the SEC,

including those under “Risk Factors” therein, and in MAC’s other

filings with the SEC. MAC cautions that the foregoing list of

factors is not exclusive. MAC cautions readers not to place undue

reliance upon any forward-looking statements, which speak only as

of the date made. MAC does not undertake or accept any obligation

or undertaking to release publicly any updates or revisions to any

forward-looking statements to reflect any change in its

expectations or any change in events, conditions, or circumstances

on which any such statement is based.

More information on potential factors that could affect MAC’s or

CSA Copper Mine’s financial results is included from time to time

in MAC’s public reports filed with the SEC. If any of these risks

materialize or MAC’s assumptions prove incorrect, actual results

could differ materially from the results implied by these

forward-looking statements. There may be additional risks that MAC

does not presently know, or that MAC currently believes are

immaterial, that could also cause actual results to differ from

those contained in the forward-looking statements. In addition,

forward-looking statements reflect MAC’s expectations, plans or

forecasts of future events and views as of the date of this

communication. MAC anticipates that subsequent events and

developments will cause its assessments to change. However, while

MAC may elect to update these forward-looking statements at some

point in the future, MAC specifically disclaims any obligation to

do so, except as required by law. These forward- looking statements

should not be relied upon as representing MAC’s assessment as of

any date subsequent to the date of this communication. Accordingly,

undue reliance should not be placed upon the forward-looking

statements.

Table 1 – Significant Drill Results QTSN, QTSC and QTSS

Upper

Hole

East (MG)

North (MG)

RL. (MG)

EOH

Azimuth

Dip

From

To

Length

Cu %

Ag g/t

System

UDD20139

5873.06

3864.05

8474.16

310.0

74.0

-49.0

47.6

52.5

4.9

3.4

19.2

QTS North

74.0

77.0

3.0

3.4

14.3

QTS North

82.0

86.0

4.0

4.1

25.0

QTS North

159.0

173.0

14.0

7.9

40.4

QTS North

UDD20142

5873.07

3863.36

8474.09

360.0

91.5

-50.0

89.1

98.9

9.8

3.8

25.0

QTS North

UDD22113

5845.08

4217.82

8515.13

380.5

57.0

-35.0

274.3

277.4

3.1

4.1

126.2

QTS North

UDD23001

5873.25

3862.57

8474.70

330.0

108.9

-37.1

115.0

119.0

4.0

3.7

14.0

QTS North

UDD23002

5873.27

3862.43

8474.25

250.0

110.7

-47.4

124.6

129.2

4.6

3.7

18.5

QTS North

UDD23005

5873.09

3862.29

8474.16

239.0

115.6

-36.0

111.3

118.6

7.3

3.0

19.2

QTS North

UDD23006

5873.29

3862.18

8474.25

276.1

116.4

-44.5

91.8

94.8

3.0

3.7

0.0

QTS North

UDD23012

5872.74

3862.43

8474.11

332.0

117.2

-57.6

25.3

28.3

3.0

3.3

16.0

QTS North

117.6

124.0

6.4

5.4

29.5

QTS North

202.7

206.0

3.3

4.4

0.0

QTS North

UDD23004

5873.10

3863.80

8474.16

294.5

79.5

-46.5

75.7

79.0

3.3

2.9

0.0

QTS North

84.5

93.2

8.7

3.7

19.8

QTS North

UDD23010

5872.93

3861.10

8474.13

282.0

122.3

-43.6

83.0

87.5

4.5

3.0

17.0

QTS North

100.8

105.2

4.4

2.9

20.5

QTS North

125.0

129.0

4.0

3.1

15.3

QTS North

155.1

159.7

4.6

5.8

39.5

QTS North

UDD23014A

5903.21

3961.92

8417.48

126.0

120.0

-65.5

51.4

56.8

5.4

2.6

12.0

QTS North

UDD23024

5904.02

3963.50

8418.80

180.0

78.0

-15.5

76.3

80.4

4.1

6.9

24.9

QTS North

102.0

118.0

16.0

10.4

38.6

QTS North

UDD23029

5873.24

3862.88

8474.70

225.0

101.5

-31.0

77.8

80.9

3.1

6.0

26.7

QTS North

UDD20144

5873.32

3862.20

8474.16

400.0

116.5

-47.0

87.5

91.5

4.0

3.5

0.0

QTS North

102.4

107.0

4.6

6.7

30.9

QTS North

128.8

133.8

5.0

4.5

17.6

QTS North

161.5

166.4

4.9

7.5

34.7

QTS North

UDD21096

5843.38

4211.32

8514.51

190.0

89.0

-7.5

169.7

176.2

6.5

5.7

30.0

QTS North

UDD22124

5843.99

4216.46

8513.45

460.7

46.0

-42.0

313.4

319.2

5.8

3.2

6.3

QTS North

UDD22125

5844.10

4216.17

8513.48

440.0

52.6

-44.5

310.9

314.3

3.4

8.7

27.6

QTS North

UDD22131

5844.12

4218.35

8513.69

510.9

32.5

-20.0

358.8

363.0

4.2

4.2

8.5

QTS North

UDD23003

5873.26

3862.81

8474.29

390.4

102.6

-47.2

95.1

101.3

6.2

3.2

0.0

QTS North

152.5

155.6

3.1

3.3

17.0

QTS North

UDD23007

5873.21

3861.87

8474.26

259.8

121.5

-35.3

120.0

125.7

5.7

3.3

17.0

QTS North

135.9

139.7

3.8

2.8

14.7

QTS North

146.0

149.9

3.9

4.0

21.7

QTS North

UDD23025

5903.75

3963.52

8418.14

218.3

79.0

-37.0

64.1

67.9

3.8

7.5

0.0

QTS North

72.0

78.0

6.0

3.7

0.0

QTS North

82.1

89.1

7.0

4.4

0.0

QTS North

114.8

134.0

19.2

10.4

31.7

QTS North

UDD23030

5873.25

3863.42

8474.89

260.0

92.5

-33.0

189.8

195.0

5.2

3.6

0.0

QTS North

UDD23031

5872.95

3863.21

8474.10

295.0

94.0

-53.0

82.6

96.1

13.5

4.6

22.2

QTS North

UDD22041

6055.77

3624.71

8702.39

165.6

96.0

-47.3

98.0

106.7

8.7

3.0

5.9

QTS Central

UDD22043

6056.02

3624.32

8702.36

162.5

103.8

-46.3

99.9

108.4

8.5

4.2

11.5

QTS Central

116.2

119.6

3.4

7.2

0.0

QTS Central

UDD22044

6055.69

3624.18

8702.44

181.8

109.3

-51.7

107.9

111.9

4.0

4.7

8.4

QTS Central

117.0

121.1

4.1

4.0

23.5

QTS Central

UDD22047

6055.45

3624.21

8702.38

200.0

108.6

-57.5

133.0

150.0

17.0

4.7

0.0

QTS Central

UDD22051

6054.00

3626.20

8703.20

225.0

134.7

-52.6

153.3

159.1

5.8

4.4

4.4

QTS Central

UDD22052

6054.81

3623.19

8702.41

266.4

139.6

-55.6

180.5

192.0

11.5

11.8

38.9

QTS Central

UDD22042

6055.67

3624.09

8702.46

185.0

94.6

-53.4

116.5

121.2

4.7

4.6

0.0

QTS Central

128.5

140.0

11.5

4.5

16.0

QTS Central

UDD22045

6055.50

3624.09

8702.39

200.0

95.4

-58.6

151.0

156.1

5.1

3.5

6.5

QTS Central

UDD22048

6055.33

3624.16

8702.39

213.0

109.6

-60.3

160.2

165.4

5.2

4.4

9.7

QTS Central

UDD22053

6055.21

3623.07

8702.40

213.0

135.2

-46.8

143.9

149.3

5.4

5.1

0.0

QTS Central

151.5

158.5

7.0

4.5

8.3

QTS Central

UDD22023

6056.73

3623.30

8702.41

162.0

115.0

-32.4

93.9

102.2

8.3

5.6

27.6

QTS Central

110.9

115.5

4.6

4.8

10.0

QTS Central

UDD22039

6056.26

3623.81

8702.49

160.0

111.0

-40.3

98.0

109.7

11.7

4.8

7.9

QTS Central

UDD22040

6055.79

3623.32

8702.47

160.5

124.0

-37.5

95.3

99.5

4.2

4.0

0.0

QTS Central

102.8

109.0

6.2

7.5

0.0

QTS Central

114.5

121.4

6.9

11.3

28.3

QTS Central

UDD22049A

6054.00

3626.20

8703.20

222.8

125.7

-58.4

152.4

178.0

25.6

6.1

21.7

QTS Central

UDD22054

6055.32

3622.80

8702.47

196.4

137.4

-39.6

136.6

143.0

6.4

5.1

17.7

QTS Central

146.5

161.0

14.5

9.0

26.6

QTS Central

QSDD056

6440.22

2988.00

10258.06

321.4

268.6

-57.2

268.4

269.2

0.8

3.5

10.0

QTSS Upper A

QSDD057C

6438.24

2959.60

10257.83

301.2

266.8

-59.9

281.2

282.9

1.7

21.3

72.3

QTSS Upper A

QSDD059

6433.27

2900.58

10257.56

294.5

272.1

-57.0

268.7

271.6

3.0

13.9

43.3

QTSS Upper A

QSDD060

6437.03

2841.27

10257.29

320.1

270.1

-59.0

293.1

293.6

0.5

9.1

90.0

QTSS Upper A

Hole

From

To

Length

Cu %

Ag g/t

Pb %

Zn %

System

QSDD060

294.40

298.70

4.3

0.8

27.7

3.9

14.2

QTSS Upper A

APPENDIX 1

JORC Code, 2012 Edition – Table 1: CSA Mineral Resource,

February 2024

Section 1 Sampling Techniques and Data

(Criteria in this section apply to all succeeding sections.)

Criteria

JORC Code explanation

Commentary

Sampling techniques

- Nature and quality of sampling (eg cut channels, random chips,

or specific specialised industry standard measurement tools

appropriate to the minerals under investigation, such as down hole

gamma sondes, or handheld XRF instruments, etc). These examples

should not be taken as limiting the broad meaning of sampling.

- Include reference to measures taken to ensure sample

representivity and the appropriate calibration of any measurement

tools or systems used.

- Aspects of the determination of mineralisation that are

Material to the Public Report. In cases where ‘industry standard’

work has been done this would be relatively simple (eg ‘reverse

circulation drilling was used to obtain 1 m samples from which 3 kg

was pulverised to produce a 30 g charge for fire assay’). In other

cases more explanation may be required, such as where there is

coarse gold that has inherent sampling problems. Unusual

commodities or mineralisation types (eg submarine nodules) may

warrant disclosure of detailed information.

- Mostly NQ and NQ2 diamond drill holes using standard tube

although in 2023 all underground drilling was NQ3 size. Minor

sampling from HQ, BQ, LTK48 and LTK60 sized diamond core holes.

Prior to mining, the mineral resource is typically defined by

drilling on a 20mN x 20 mRL for all systems; however, QTS North is

drilled at it tightest to a 20 mN x 37.5 mRL grid. Hole spacing

increases to 40 mN x 40 mRL at depth and to 40 mN x 75 mRL below

this.

- Drillhole collars were picked up by site underground surveyors

and hole paths by downhole magnetic surveys. Diamond core is used

to obtain high quality samples that are logged for lithological,

structural, geotechnical and other attributes.

- Half core samples are mostly 1m in length with sample weights

averaging 1.9kg. The cutting and sampling process is carried out at

CSA Mine. These samples are crushed and pulverised to produce a sub

sample for analysis by aqua regia digestion and ICP-AES analysis

for a suit of elements including Cu, Ag, Pb, Zn, Au, Fe and S.

High-grade assays are re-analysed to ensure maximum Cu recovery.

Sample preparation and assaying is carried out by independent

laboratory, Australian Laboratory Services (“ALS”) in Orange,

NSW.

Drilling techniques

- Drill type (eg core, reverse circulation, open-hole hammer,

rotary air blast, auger, Bangka, sonic, etc) and details (eg core

diameter, triple or standard tube, depth of diamond tails,

face-sampling bit or other type, whether core is oriented and if

so, by what method, etc).

- Mostly NQ and NQ2 diamond drill holes using standard tube with

conversion to NQ3 exclusively in 2023. Minor sampling from HQ, BQ,

LTK48 and LTK60 sized diamond core holes.

Drill sample recovery

- Method of recording and assessing core and chip sample

recoveries and results assessed.

- Measures taken to maximise sample recovery and ensure

representative nature of the samples.

- Whether a relationship exists between sample recovery and grade

and whether sample bias may have occurred due to preferential

loss/gain of fine/coarse material.

- Core recovery is measured during the logging process. Driller

depth markers and core presentation is checked and corrected where

necessary.

- Core is reconstructed into continuous runs -depths are checked

against the depths recorded on the core blocks.

- Overall, core recovery is 97.5%. Low core recovery does not

impact the quality of the CSA data set.

Logging

- Whether core and chip samples have been geologically and

geotechnically logged to a level of detail to support appropriate

Mineral Resource estimation, mining studies and metallurgical

studies.

- Whether logging is qualitative or quantitative in nature. Core

(or costean, channel, etc.) photography.

- The total length and percentage of the relevant intersections

logged.

- Geotechnical logging has been carried out on diamond holes

since 2002 to aid in the mine design process. Geological logging of

diamond drill core, to a level suitable for the: a) interpretation

of domains based on geology and sulphide content. b) for

metallurgical sample selection.

- Core is logged in full by geologists for lithology, mineralogy,

structure, RQD. Core is photographed wet prior to sampling.

- All drillholes are logged in full.

Sub-sampling techniques and sample

preparation

- If core, whether cut or sawn and whether quarter, half or all

core taken.

- If non-core, whether riffled, tube sampled, rotary split, etc

and whether sampled wet or dry.

- For all sample types, the nature, quality and appropriateness

of the sample preparation technique.

- Quality control procedures adopted for all sub-sampling stages

to maximise representivity of samples.

- Measures taken to ensure that the sampling is representative of

the in situ material collected, including for instance results for

field duplicate/second-half sampling.

- Whether sample sizes are appropriate to the grain size of the

material being sampled.

- Sample intervals of typically 1m lengths are marked on the core

by the Geologist. Core is cut in half using an Almonte core saw.

Sample intervals are marked in the tray prior to placing half core

in calico sample bags. Prior to 2017, bulk density was measured

using the Archimedes method at a rate of one interval per core tray

Since January 2017, every second hole had a specific gravity

determination (via the Archimedes method) at the ALS assaying

laboratory.

- Not applicable – all drilling is diamond core.

- Sample preparation of diamond core follows industry best

practice involving coarse crushing of half core samples down to 70%

passing 2mm followed by pulverization of the entire sample to a

grind size of 85% passing 75 micron.

- All QAQC assay data is interrogated upon return from the

laboratory using standard QAQC practices. There are strict

procedures for processing of the core from markup to placing in a

sample bag.

- Field QC procedures involve the use of certified reference

material as assay standards, along with blanks, duplicates and

barren waste. The insertion rate for standards and field duplicates

(second half core) is 1 in 30.

- Sample sizes are considered appropriate for the semi-massive to

massive style of sulphide mineralisation. Mine reconciliation data

supports this.

Quality of assay data and laboratory

tests

- The nature, quality and appropriateness of the assaying and

laboratory procedures used and whether the technique is considered

partial or total.

- For geophysical tools, spectrometers, handheld XRF instruments,

etc., the parameters used in determining the analysis including

instrument make and model, reading times, calibrations factors

applied and their derivation, etc.

- Nature of quality control procedures adopted (e.g. standards,

blanks, duplicates, external laboratory checks) and whether

acceptable levels of accuracy (i.e. lack of bias) and precision

have been established.

- ALS procedure ME-OG46 is followed and is considered to report

total Cu recovery. The analytical technique uses aqua regia to

digest the sample followed by conventional ICP-AES analysis for a

list of elements including Cu, Ag, Pb, Zn, Fe and S. Most of the

assay records from holes drilled prior to 2000 have been assayed

using an unknown assay technique and are flagged as such in the

acQuire database. Assessment of the potential impact of these

assays on the resource estimate indicates that the only likely

significant effect is on the Eastern and Western Systems mineral

resource above 9070 mRL and 9300 mRL. respectively.

- No geophysical tools were used to determine element

concentrations used in the resource estimation.

- Sample preparation checks at the crushing and pulverizing stage

were carried out by the laboratory as part of their internal

procedures. Laboratory QAQC involves the use of internal lab

standards using certified reference material as part of the in-

house procedures. Field duplicates have been collected since 2002,

the difference between the mean Cu values on an annual basis is

0.02% Cu and correlation co-efficient value of 0.99 confirming no

global bias. For Ag the mean duplicate values on an annual basis

have a difference 0.05 g/t and correlation co-efficient value of

0.96; there is no global bias, however bias is often attributed for

the higher values and is treated using top- cuts. Overall, there

are 14 types of standards in the database. During 2023, eight

Certified Reference Material standards with values ranging from

blank to 14.7% Cu were inserted into the sample stream.

Verification of sampling and

assaying

- The verification of significant intersections by either

independent or alternative company personnel.

- The use of twinned holes.

- Documentation of primary data, data entry procedures, data

verification, data storage (physical and electronic)

protocols.

- Discuss any adjustment to assay data.

- Infill drilling prior to level development and geological

mapping is used to verify high grade Cu zones. Chalcopyrite

mineralogy is quantified visually during logging and provides a

valid tool for assay correlation. Zones of Western and Eastern

mineralisation defined by historic drilling were re-drilled to

improve estimation quality.

- Twinned holes are not routinely drilled – mapping and

reconciliation data is used to track grade accuracy and

repeatability.

- Primary data was collected on paper log sheets and Excel

templates. All data was imported into the on-site acQuire database

which runs a series of internal validation procedures.

- No adjustments or calibrations were made to any assay data used

in the estimate.

Location of data points

- Accuracy and quality of surveys used to locate drill holes

(collar and down-hole surveys), trenches, mine workings and other

locations used in Mineral Resource estimation.

- Specification of the grid system used.

- Quality and adequacy of topographic control.

- Hole collars were picked up by site underground surveyors. A

small proportion of hole collars are based on design coordinates

and do not have final survey coordinates. The holes are considered

to have an error of <2.0m in the east-west orientation –

subsequent infill drilling confirms mineralisation continuity and

location of the holes with un-surveyed collars. Drillholes are

routinely surveyed downhole using a multi-shot camera at 30m

intervals. At the end of a drillhole, a multi-shot is run from end

of hole to the collar at 3m intervals.

- A mine grid coordinate system is used – survey data is captured

using the mine grid coordinates, therefore a grid transfer process

is not required for the resource estimation process.

- The surface topography is adequately defined and includes the

location of mine infrastructure.

Data spacing and distribution

- Data spacing for reporting of Exploration Results.

- Whether the data spacing and distribution is sufficient to

establish the degree of geological and grade continuity appropriate

for the Mineral Resource and Ore Reserve estimation procedure(s)

and classifications applied.

- Whether sample compositing has been applied.

- Prior to mining the mineral resource is typically defined by

drilling on a 20 mN x 20 mRL for all the systems; however, QTS

North is drilled at tightest to a 20 mN x 37.5 mRL grid. Hole

spacing increases to 40 mN x 40 mRL at depth and to 40 mN x 75 mRL

below this. Hole spacing is in important factor in final resource

classification.

- A guide to assay grade continuity was done by comparing sample

grades with mapping. Assay grade continuity is quantified by

variography studies and built into the resource model using copper

kriging metrics to assist classification in accordance with the

2012 JORC Code.

- Samples are composited to 1m intervals for estimation

purposes.

Orientation of data in relation to

geological structure

- Whether the orientation of sampling achieves unbiased sampling

of possible structures and the extent to which this is known,

considering the deposit type.

- If the relationship between the drilling orientation and the

orientation of key mineralised structures is considered to have

introduced a sampling bias, this should be assessed and reported if

material.

- Drillholes generally intersect mineralisation orthogonally. The

steep plunge of the mineralisation means deeper holes often follow

down plunge trends.

- De-clustered assay mean grades are compared to grade estimates

to ensure the influence of de-clustering is minimised in the

estimation. Clustering in the deeper parts of the resource has been

considered in the resource classification process.

Sample security

- The measures taken to ensure sample security.

- Chain of custody is managed by CSA. Samples are stored at the

mine site and delivered by a contract transport company to the ALS

laboratory in Orange, NSW. Tracking sheets are used by the mine and

laboratory to communicate dispatch and arrival details for each

batch.

Audits or reviews

- The results of any audits or reviews of sampling techniques and

data.

- Snowden Mining Industry Consultants reviewed the CSA mineral

resource estimation and reporting procedures in 2005 and assisted

with improvements. Xstract Mining Consultants assisted with the

preparation of the June 2010 mineral resource including improvement

recommendations. A CMPL Corporate audit was completed in 2015. All

of the above audits/reviews included sections on data collection

techniques. Early in 2017, Optiro Pty. Ltd completed a study on the

QTS North resource, focused on determining the optimum drill

spacing.

Section 2 Reporting of Exploration Results

(Criteria listed in the preceding section also apply to this

section.)

Criteria

JORC Code explanation

Commentary

Mineral tenement and land tenure

status

- Type, reference name/number, location and ownership including

agreements or material issues with third parties such as joint

ventures, partnerships, overriding royalties, native title

interests, historical sites, wilderness or national park and

environmental settings.

- The security of the tenure held at the time of reporting along

with any known impediments to obtaining a licence to operate in the

area.

- The CSA Mine is located on Consolidated Mining Lease No 5

(1992) (CML5), which is owned and operated by Cobar Management Pty

Limited (CMPL). CMPL is wholly owned by Metals Acquisition Limited.

CMPL holds Exploration Licence No 5693 (EL5693), which encompasses

CML5 and Exploration Licence No 5983 (EL5983), which lies 7km north

of the CSA Mine.

- The expiry date for CML5 is 24th June, 2028.

Exploration done by other

parties

- Acknowledgment and appraisal of exploration by other

parties.

- Other parties have not been involved on exploration

activities.

Geology

- Deposit type, geological setting and style of

mineralisation.

- CSA Mine mineralisation style is a classic Cobar style deposit.

Mineralisation is shear hosted within the CSA Siltstone occurring

as steeply plunging dilation zones containing veined, semi-massive

and massive sulphides. The major ore bearing sulphide is

chalcopyrite with lesser cubanite. Pyrrhotite is the principal

sulphide gangue.

Drill hole Information

- A summary of all information material to the understanding of

the exploration results including a tabulation of the following

information for all Material drill holes:

- easting and northing of the drill hole collar

- elevation or RL (Reduced Level – elevation above sea level in

metres) of the drill hole collar

- dip and azimuth of the hole

- down hole length and interception depth

- hole length.

- If the exclusion of this information is justified on the basis

that the information is not Material and this exclusion does not

detract from the understanding of the report, the Competent Person

should clearly explain why this is the case.

- See table below.

- All drill holes have been reported – no information has been

excluded.

Borehole

Intersections - Sep 1st 2023 to Feb 29th 2024

Hole

East (MG)

North (MG)

RL. (MG)

EOH

Azimuth

Dip

From

To

Length

Cu %

Ag g/t

System

UDD20139

5873.06

3864.05

8474.16

310.0

74.0

-49.0

47.6

52.5

4.9

3.4

19.2

QTS North

74.0

77.0

3.0

3.4

14.3

QTS North

82.0

86.0

4.0

4.1

25.0

QTS North

159.0

173.0

14.0

7.9

40.4

QTS North

UDD20142

5873.07

3863.36

8474.09

360.0

91.5

-50.0

89.1

98.9

9.8

3.8

25.0

QTS North

UDD22113

5845.08

4217.82

8515.13

380.5

57.0

-35.0

274.3

277.4

3.1

4.1

126.2

QTS North

UDD23001

5873.25

3862.57

8474.70

330.0

108.9

-37.1

115.0

119.0

4.0

3.7

14.0

QTS North

UDD23002

5873.27

3862.43

8474.25

250.0

110.7

-47.4

124.6

129.2

4.6

3.7

18.5

QTS North

UDD23005

5873.09

3862.29

8474.16

239.0

115.6

-36.0

111.3

118.6

7.3

3.0

19.2

QTS North

UDD23006

5873.29

3862.18

8474.25

276.1

116.4

-44.5

91.8

94.8

3.0

3.7

0.0

QTS North

UDD23012

5872.74

3862.43

8474.11

332.0

117.2

-57.6

25.3

28.3

3.0

3.3

16.0

QTS North

117.6

124.0

6.4

5.4

29.5

QTS North

202.7

206.0

3.3

4.4

0.0

QTS North

UDD23004

5873.10

3863.80

8474.16

294.5

79.5

-46.5

75.7

79.0

3.3

2.9

0.0

QTS North

84.5

93.2

8.7

3.7

19.8

QTS North

UDD23010

5872.93

3861.10

8474.13

282.0

122.3

-43.6

83.0

87.5

4.5

3.0

17.0

QTS North

100.8

105.2

4.4

2.9

20.5

QTS North

125.0

129.0

4.0

3.1

15.3

QTS North

155.1

159.7

4.6

5.8

39.5

QTS North

UDD23014A

5903.21

3961.92

8417.48

126.0

120.0

-65.5

51.4

56.8

5.4

2.6

12.0

QTS North

UDD23024

5904.02

3963.50

8418.80

180.0

78.0

-15.5

76.3

80.4

4.1

6.9

24.9

QTS North

102.0

118.0

16.0

10.4

38.6

QTS North

UDD23029

5873.24

3862.88

8474.70

225.0

101.5

-31.0

77.8

80.9

3.1

6.0

26.7

QTS North

UDD20144

5873.32

3862.20

8474.16

400.0

116.5

-47.0

87.5

91.5

4.0

3.5

0.0

QTS North

102.4

107.0

4.6

6.7

30.9

QTS North

128.8

133.8

5.0

4.5

17.6

QTS North

161.5

166.4

4.9

7.5

34.7

QTS North

UDD21096

5843.38

4211.32

8514.51

190.0

89.0

-7.5

169.7

176.2

6.5

5.7

30.0

QTS North

UDD22124

5843.99

4216.46

8513.45

460.7

46.0

-42.0

313.4

319.2

5.8

3.2

6.3

QTS North

UDD22125

5844.10

4216.17

8513.48

440.0

52.6

-44.5

310.9

314.3

3.4

8.7

27.6

QTS North

UDD22131

5844.12

4218.35

8513.69

510.9

32.5

-20.0

358.8

363.0

4.2

4.2

8.5

QTS North

UDD23003

5873.26

3862.81

8474.29

390.4

102.6

-47.2

95.1

101.3

6.2

3.2

0.0

QTS North

152.5

155.6

3.1

3.3

17.0

QTS North

UDD23007

5873.21

3861.87

8474.26

259.8

121.5

-35.3

120.0

125.7

5.7

3.3

17.0

QTS North

135.9

139.7

3.8

2.8

14.7

QTS North

146.0

149.9

3.9

4.0

21.7

QTS North

UDD23025

5903.75

3963.52

8418.14

218.3

79.0

-37.0

64.1

67.9

3.8

7.5

0.0

QTS North

72.0

78.0

6.0

3.7

0.0

QTS North

82.1

89.1

7.0

4.4

0.0

QTS North

114.8

134.0

19.2

10.4

31.7

QTS North

UDD23030

5873.25

3863.42

8474.89

260.0

92.5

-33.0

189.8

195.0

5.2

3.6

0.0

QTS North

UDD23031

5872.95

3863.21

8474.10

295.0

94.0

-53.0

82.6

96.1

13.5

4.6

22.2

QTS North

UDD22041

6055.77

3624.71

8702.39

165.6

96.0

-47.3

98.0

106.7

8.7

3.0

5.9

QTS Central

UDD22043

6056.02

3624.32

8702.36

162.5

103.8

-46.3

99.9

108.4

8.5

4.2

11.5

QTS Central

116.2

119.6

3.4

7.2

0.0

QTS Central

UDD22044

6055.69

3624.18

8702.44

181.8

109.3

-51.7

107.9

111.9

4.0

4.7

8.4

QTS Central

117.0

121.1

4.1

4.0

23.5

QTS Central

UDD22047

6055.45

3624.21

8702.38

200.0

108.6

-57.5

133.0

150.0

17.0

4.7

0.0

QTS Central

UDD22051

6054.00

3626.20

8703.20

225.0

134.7

-52.6

153.3

159.1

5.8

4.4

4.4

QTS Central

UDD22052

6054.81

3623.19

8702.41

266.4

139.6

-55.6

180.5

192.0

11.5

11.8

38.9

QTS Central

UDD22042

6055.67

3624.09

8702.46

185.0

94.6

-53.4

116.5

121.2

4.7

4.6

0.0

QTS Central

128.5

140.0

11.5

4.5

16.0

QTS Central

UDD22045

6055.50

3624.09

8702.39

200.0

95.4

-58.6

151.0

156.1

5.1

3.5

6.5

QTS Central

UDD22048

6055.33

3624.16

8702.39

213.0

109.6

-60.3

160.2

165.4

5.2

4.4

9.7

QTS Central

UDD22053

6055.21

3623.07

8702.40

213.0

135.2

-46.8

143.9

149.3

5.4

5.1

0.0

QTS Central

151.5

158.5

7.0

4.5

8.3

QTS Central

UDD22023

6056.73

3623.30

8702.41

162.0

115.0

-32.4

93.9

102.2

8.3

5.6

27.6

QTS Central

110.9

115.5

4.6

4.8

10.0

QTS Central

UDD22039

6056.26

3623.81

8702.49

160.0

111.0

-40.3

98.0

109.7

11.7

4.8

7.9

QTS Central

UDD22040

6055.79

3623.32

8702.47

160.5

124.0

-37.5

95.3

99.5

4.2

4.0

0.0

QTS Central

102.8

109.0

6.2

7.5

0.0

QTS Central

114.5

121.4

6.9

11.3

28.3

QTS Central

UDD22049A

6054.00

3626.20

8703.20

222.8

125.7

-58.4

152.4

178.0

25.6

6.1

21.7

QTS Central

UDD22054

6055.32

3622.80

8702.47

196.4

137.4

-39.6

136.6

143.0

6.4

5.1

17.7

QTS Central

146.5

161.0

14.5

9.0

26.6

QTS Central

Note:

Borehole intersects criteria based on

Copper grade >2.5% and >3m.

Hole

East (MG)

North(MG)

RL. (MG)

EOH

Azimuth

Dip

From

To

Length

Cu %

Ag g/t

System

QSDD056

6440.22

2988.00

10258.06

321.4

268.6

-57.2

268.4

269.2

0.8

3.5

10.0

QTSS Upper A

QSDD057C

6438.24

2959.60

10257.83

301.2

266.8

-59.9

281.2

282.9

1.7

21.3

72.3

QTSS Upper A

QSDD059

6433.27

2900.58

10257.56

294.5

272.1

-57.0

268.7

271.6

3.0

13.9

43.3

QTSS Upper A

QSDD060

6437.03

2841.27

10257.29

320.1

270.1

-59.0

293.1

293.6

0.5

9.1

90.0

QTSS Upper A

Note:

The intersects criteria is not apply to

QTSS Upper A due to its mineralisation style as narrow vein.

Zinc Results

Hole

Sample ID

From

To

Length

Cu %

Ag g/t

Pb %

Zn %

QSDD060

CU157624

285.50

286.10

0.6

0.0

2.0

0.6

1.0

QSDD060

CU157632

293.60

294.40

0.8

1.6

31.0

0.2

1.7

QSDD060

CU157633

294.40

295.20

0.8

0.6

24.0

7.0

16.8

QSDD060

CU157634

295.20

295.90

0.7

0.6

16.0

2.5

25.2

QSDD060

CU157637

297.70

298.70

1.0

1.2

64.0

9.7

30.0

Data aggregation methods

- In reporting Exploration Results, weighting averaging

techniques, maximum and/or minimum grade truncations (eg cutting of

high grades) and cut-off grades are usually Material and should be

stated.

- Where aggregate intercepts incorporate short lengths of high

grade results and longer lengths of low grade results, the

procedure used for such aggregation should be stated and some

typical examples of such aggregations should be shown in

detail.

- The assumptions used for any reporting of metal equivalent

values should be clearly stated.

- The Exploration Results criteria for borehole intersects is

based on Cu grade > 2.5% and > 3m. This criteria is not apply

for QTS South Upper A due to its mineralization style as narrow

vein. Cu and Ag grade calculated by length weighted average.

- No top-cut (grade capping) has been used.

- No metal equivalent values are used.

Relationship between mineralisation

widths and intercept lengths

- These relationships are particularly important in the reporting

of Exploration Results.

- If the geometry of the mineralisation with respect to the drill

hole angle is known, its nature should be reported.

- If it is not known and only the down hole lengths are reported,

there should be a clear statement to this effect (eg ‘down hole

length, true width not known’).

- Overall, the mineralisation structures are trending North-South

and vertical.

- The drilling programs are considering drillhole with azimuth

oriented to improve the intercepted angle between mineralization

structures and drillhole.

- Only down hole length is considered for reporting

purposes.

Diagrams

- Appropriate maps and sections (with scales) and tabulations of

intercepts should be included for any significant discovery being

reported These should include, but not be limited to a plan view of

drill hole collar locations and appropriate sectional views.

- See figures below.

Balanced reporting

- Where comprehensive reporting of all Exploration Results is not

practicable, representative reporting of both low and high grades

and/or widths should be practiced to avoid misleading reporting of

Exploration Results.

- All exploration results are reported with all drill holes and

significant intercepts listed in the included table above.

Other substantive exploration

data

- Other exploration data, if meaningful and material, should be

reported including (but not limited to): geological observations;

geophysical survey results; geochemical survey results; bulk

samples – size and method of treatment; metallurgical test results;

bulk density, groundwater, geotechnical and rock characteristics;

potential deleterious or contaminating substances.

- There is no other substantive exploration data.

Further work

- The nature and scale of planned further work (eg tests for

lateral extensions or depth extensions or large-scale step-out

drilling).

- Diagrams clearly highlighting the areas of possible extensions,

including the main geological interpretations and future drilling

areas, provided this information is not commercially

sensitive.

- Drill holes are planned to test lens extensions along strike

and vertical axis.

- The long section above shows QTS North and QTS Central resource

as targets for drilling activities.

View source

version on businesswire.com: https://www.businesswire.com/news/home/20240319036286/en/

Mick McMullen Chief Executive Officer Metals Acquisition Limited

investors@metalsacqcorp.com

Morne Engelbrecht Chief Financial Officer Metals Acquisition

Limited

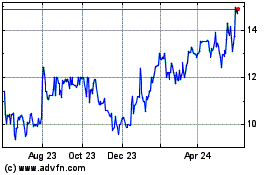

MAC Copper (NYSE:MTAL)

Historical Stock Chart

From Dec 2024 to Jan 2025

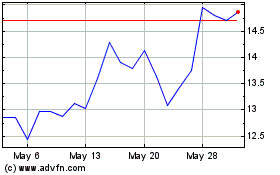

MAC Copper (NYSE:MTAL)

Historical Stock Chart

From Jan 2024 to Jan 2025