Hudson Reports 94% Aluminum Extraction from Initial Leaching Testwork for the White Mountain Anorthosite Project in Greenland

January 23 2013 - 7:00AM

Marketwired Canada

HUDSON RESOURCES INC. (TSX VENTURE:HUD)(OTCQX:HUDRF) (the "Company") is pleased

to announce the following update on the metallurgical testwork program for

aluminum leaching extraction from its White Mountain anorthosite (calcium

feldspar) project in Greenland. Alumina production is one of three potential

revenue streams Hudson is analysing for the White Mountain project.

The testwork is being undertaken at SGS Canada Inc.'s Lakefield facility under

the direction of Hudson's consulting metallurgist, John R. Goode, P.Eng. Initial

testwork using hydrochloric acid (HCl) has demonstrated the high solubility of

the anorthosite material at normal atmospheric pressure and relatively low

temperatures. Aluminum recoveries ranged from 89.7% to 93.7%. The highest

recovery was achieved at a temperature of 110 Celsius and an HCl strength of

30%. The White Mountain anorthosite rock averages approximately 30% aluminum

oxide (Al2O3) and 1.25% iron oxide (Fe2O3).

Downstream testwork on leach solutions is ongoing and includes aluminum chloride

precipitation, alumina production and acid regeneration testing. Once this

testwork is completed, Hudson will initiate a scoping study to determine the

preliminary economics of producing an alumina product and potential silica and

calcium by-products. Testwork is expected to be completed in the second quarter.

James Tuer, Hudson's President, stated, "We are very excited with these initial

leach results which demonstrate that recoveries in excess of 90% aluminum can be

achieved using standard technologies and under moderate conditions. The high

solubility of our White Mountain Anorthosite, which is unique to high calcium

feldspars, makes it an excellent candidate for potential alumina production. As

well as containing high aluminum, its low iron content should help reduce

processing costs. With Alcoa proposing an aluminum smelter in Greenland and

three smelters currently operating in Iceland, we are well positioned to provide

alumina to end users if we can provide it at a competitive price compared to

conventional alumina being produced from bauxite using the Bayer process. It may

also be possible to provide an added benefit by utilizing the 15% calcium in the

rock to capture CO2 and thereby lower greenhouse gas emissions, which is a key

objective of the aluminum industry."

Hudson's White Mountain anorthosite is relatively unique in that it has high

concentrations of aluminum, silica and calcium, with little to no contaminants

and low iron. Hudson has determined that the White Mountain anorthosite has

three potential industrial applications:

1. As a new source of alumina to supply aluminum smelters;

2. As a new source of feedstock to the high end fiberglass (E-glass) industry; and

3. As a new source of filler material. Fillers are a significant component in

the plastics and paints industries.

Hudson commenced exploration on the White Mountain Project in January 2012 and

has completed over 4,300 meters of drilling in 45 drill holes at White Mountain.

A resource model is expected to be completed within the next month. Processing

of a 122 tonne bulk sample is expected to start shortly at the Saskatchewan

Research Council's pilot plant in Saskatoon. Based on bench scale testing, the

material requires minimal processing: crushing, grinding, magnetic separation

and milling. The processed bulk sample material will be provided to potential

end users in the E-glass industry for testing in their furnaces. The Company has

also initiated baseline environmental studies with the objective of submitting

an application for a mining license in early 2014.

The White Mountain Project is owned 100% by Hudson. The Project is located on

tidewater approximately 40 km from the Company's 100% owned rare earth element

(REE) project. White Mountain is envisioned as an open pit mining operation

similar in scope to a quarry. The Company remains well-financed with

approximately $7 million in working capital.

Dr. Michael Druecker is a qualified person as defined by National Instrument

43-101 and reviewed the preparation of the scientific and technical geological

information in this press release.

John R. Goode is the Qualified Person as defined by National Instrument 43-101

who reviewed the preparation of the scientific and technical metallurgical

information in this press release.

ON BEHALF OF THE BOARD OF DIRECTORS

James Tuer, President

Forward-Looking Statements

This news release includes certain forward-looking statements or information.

All statements other than statements of historical fact included in this news

release, including, without limitation, statements regarding plans for the

completion of a financing and the intended terms and use of proceeds thereof,

and other future plans and objectives of the Company are forward-looking

statements that involve various risks and uncertainties. There can be no

assurance that such statements will prove to be accurate and actual results and

future events could differ materially from those anticipated in such statements.

Important factors that could cause actual results to differ materially from the

Company's plans or expectations include market prices, general economic, market

or business conditions, regulatory changes, timeliness of government or

regulatory approvals and other risks detailed herein and from time to time in

the filings made by the Company with securities regulators. The Company

expressly disclaims any intention or obligation to update or revise any

forward-looking statements whether as a result of new information, future events

or otherwise except as otherwise required by applicable securities legislation.

FOR FURTHER INFORMATION PLEASE CONTACT:

Hudson Resources Inc.

James Tuer

President

604-628-5002 or 604-688-3415

604-688-3452 (FAX)

tuer@hudsonresources.ca

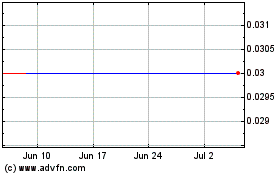

Hudson Resources (TSXV:HUD)

Historical Stock Chart

From May 2024 to Jun 2024

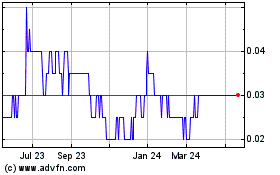

Hudson Resources (TSXV:HUD)

Historical Stock Chart

From Jun 2023 to Jun 2024