UNITED

STATES

SECURITIES AND EXCHANGE

COMMISSION

WASHINGTON,

D.C. 20549

FORM

10-K

þ

ANNUAL REPORT UNDER SECTION 13 OR

15(D) OF THE SECURITIES EXCHANGE ACT OF 1934

For the

fiscal year ended October 31, 2009

|

|

MERA

PHARMACEUTICALS, INC.

|

|

|

|

(Exact

name of registrant as specified in charter)

|

|

|

DELAWARE

|

|

033-23460

|

|

04-3683628

|

|

(State

or other jurisdiction

of

incorporation)

|

|

(Commission

File

Number)

|

|

(IRS

Employer

Identification

No.)

|

|

|

73-4460

QUEEN KA'AHUMANU HIGHWAY, SUITE 110, KAILUA-KONA, HAWAII,

96740

|

|

|

|

(Address

of principal executive offices)

|

|

|

|

(808)

326-9301

|

|

|

|

(Registrant’s

Telephone Number, including Area Code)

|

|

Securities

registered under Section 12(b) of the Act:

|

Title

of each class

|

|

Name

of each exchange on which registered

|

|

|

|

|

Securities

registered under Section 12(g) of the Exchange Act: NONE

Indicate

by check mark if the registrant is a well-known seasoned issuer, as defined in

Rule 405 of the Securities Act. Yes

o

No

þ

Indicate

by check mark if the registrant is not required to file reports pursuant to

Section 13 or Section 15(d) of the Act. Yes

o

No

þ

Indicate

by check mark whether the registrant (1) has filed all reports required to be

filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the

preceding 12 months (or for such shorter period that the registrant was required

to file such reports), and (2) has been subject to such filing requirements for

the past 90 days. Yes

þ

No

o

Indicate

by check mark whether the registrant has submitted electronically and posted on

its corporate Web site, if any, every Interactive Data File required to be

submitted and posted pursuant to Rule 405 of Regulation S-T (§ 232.405

of this chapter) during the preceding 12 months (or for such shorter period that

the registrant was required to submit and post such files). Yes

o

No

o

Indicate

by check mark if disclosure of delinquent filers pursuant to Item 405 of

Regulation S-K (§229.405 of this chapter) is not contained herein, and will not

be contained, to the best of registrant’s knowledge, in definitive proxy or

information statements incorporated by reference in Part III of this Form 10-K

or any amendment to this Form 10-K.

þ

Indicate

by check mark whether the registrant is a large accelerated filer, an

accelerated filer, a non-accelerated filer, or a smaller reporting

company.

|

Large

accelerated filer

|

¨

|

Accelerated

filer

|

¨

|

|

Non-accelerated

filer

(Do

not check if a smaller reporting company)

|

¨

|

Smaller

reporting company

|

þ

|

Indicate

by check mark whether the registrant is a shell company (as defined in

Rule 12b-2 of the Exchange Act) Yes

o

No

þ

Mera

Pharmaceuticals' revenues for its most recent fiscal year:

$599,091.

The

aggregate market value of the common equity held by non-affiliates computed by

reference to the price at which the stock was sold, or the average bid and asked

prices of such stock as reported on the NASD Pink Sheets, as of October 31,

2009 is $2,738,847.

The

number of shares outstanding of common equity, as of October 31, 2009, was

547,769,515

shares

of Common Stock, $0.0001 par value.

DOCUMENTS

INCORPORATED BY REFERENCE

None

MERA

PHARMACEUTICALS, INC.

TABLE

OF CONTENTS

|

|

|

|

Page

|

|

|

|

|

|

|

|

|

1

|

|

|

|

|

7

|

|

|

|

|

15

|

|

|

|

|

15

|

|

|

|

|

15

|

|

|

|

|

|

|

|

|

16

|

|

|

|

|

17

|

|

|

|

|

19

|

|

|

|

|

19

|

|

|

|

|

20

|

|

|

|

|

20

|

|

|

|

|

|

|

|

|

21

|

|

|

|

|

22

|

|

|

|

|

23

|

|

|

|

|

24

|

|

|

|

|

24

|

|

|

|

|

|

|

|

|

25

|

|

|

|

26

|

|

|

|

F-1

|

|

|

|

F-7

|

PART I

THIS

ANNUAL REPORT ON FORM 10-KSB CONTAINS CERTAIN FORWARD-LOOKING STATEMENTS WITHIN

THE MEANING OF SECTION 21E OF THE SECURITIES EXCHANGE ACT OF 1934, AS AMENDED,

INCLUDING STATEMENTS THAT INDICATE WHAT WE "BELIEVE", "EXPECT" AND "ANTICIPATE"

OR SIMILAR EXPRESSIONS. THESE STATEMENTS INVOLVE KNOWN AND UNKNOWN RISKS,

UNCERTAINTIES AND OTHER FACTORS WHICH MAY CAUSE OUR ACTUAL RESULTS, PERFORMANCE

OR ACHIEVEMENTS TO DIFFER MATERIALLY FROM THOSE EXPRESSED OR IMPLIED BY SUCH

FORWARD-LOOKING STATEMENTS. SUCH FACTORS INCLUDE, AMONG OTHERS, THE INFORMATION

CONTAINED UNDER THE CAPTION "PART II, ITEM 6. MANAGEMENT'S DISCUSSION AND

ANALYSIS OF FINANCIAL CONDITIONS AND RESULTS OF OPERATIONS" AND ELSEWHERE IN

THIS ANNUAL REPORT. YOU SHOULD NOT PLACE UNDUE RELIANCE ON THESE FORWARD-LOOKING

STATEMENTS, WHICH REFLECT OUR MANAGEMENT'S ANALYSIS ONLY AS OF THE DATE OF THIS

ANNUAL REPORT. WE UNDERTAKE NO OBLIGATION TO PUBLICLY RELEASE THE RESULTS OF ANY

REVISION OF THESE FORWARD-LOOKING STATEMENTS. YOU ARE STRONGLY URGED TO READ THE

INFORMATION SET FORTH UNDER THE CAPTION "PART II, ITEM 6, MANAGEMENT'S

DISCUSSION AND ANALYSIS OF FINANCIAL CONDITIONS AND RESULTS OF OPERATION - RISK

FACTORS" FOR A MORE DETAILED DESCRIPTION OF THESE SIGNIFICANT RISKS AND

UNCERTAINTIES.

HISTORY

Mera

Pharmaceuticals, Inc. is the successor issuer to Aquasearch, Inc. (the

"Predecessor"), which was incorporated in Colorado in 1987 for the purpose of

developing useful products from aquatic microorganisms and making their

production economically feasible. On July 25, 2002, the Predecessor merged

with and into Mera Pharmaceuticals, Inc., a Delaware corporation formed in

June 2002 for the purpose of changing the corporation's name to Mera

Pharmaceuticals, Inc. and changing its state of incorporation from Colorado to

Delaware (the "Reincorporation Merger"). Mera Pharmaceuticals continues the

operations and business of the Predecessor. Each share of the Predecessor's

common stock outstanding at the time of the Reincorporation Merger was exchanged

for one share of common stock of Mera. Following the Reincorporation Merger, the

former stockholders of the Predecessor continued to own 100% of the Company's

issued and outstanding capital stock.

On

September 16, 2002, Aqua RM Co., Inc., a privately-held, non-operating

Delaware corporation established specifically for the purpose of facilitating

the Predecessor's reorganization under Chapter 11 of the U.S. Bankruptcy Code

("Aqua RM"), merged with and into the Company (the "Reorganization Merger"). The

Company was the surviving corporation of the Reorganization Merger. Each share

of Aqua RM common stock outstanding at the time of the Reincorporation Merger

was exchanged for 100 shares of the Company's common stock. Following the

Reorganization Merger, former Aqua RM stockholders held approximately 68% of the

Company's common stock. The Reorganization Merger was the last material event in

the fulfillment of the Company's Chapter 11 Plan of Reorganization.

OVERVIEW

OF THE COMPANY'S BUSINESS

The

Company develops and commercializes natural products derived principally from

microalgae using our patented photobioreactor technology known as the Mera

Growth Module ("MGM").

Microalgae

are a diverse group of microscopic plants estimated to consist of more than

30,000 species. They have a wide range of physiological and biochemical

characteristics. Microalgae produce many different substances and bioactive

compounds that have existing and potential applications in a variety of

commercial areas, including human nutrition, pharmaceuticals, and other high

value commodities such as bio-diesel.

The major

challenge to commercial exploitation of microalgae has been the availability of

photobioreactors large enough to achieve commercial production levels at an

economic cost. A photobioreactor is a fermentation system that is used to grow

photosynthetic organisms. At more than 6,000 gallons (25,000 liters), our

proprietary MGM is one of the largest photobioreactors in existence and one of

the few photobioreactors used for commercial production of

microalgae.

The MGM

incorporates a very high level of computerized process control, resulting in a

higher degree of reproducible performance at high efficiency levels. This

increased reliability is due in large measure to the use of turbulence to

control the exposure of the algae to light and nutrients at a frequency that

improves yields. Mera owns the basic patent for use of turbulence in this way.

Our patents, proprietary process controls and the very low cost of constructing

the MGM make the MGM very advanced, cost-effective and scalable.

The

Company has used its advantage in photobioreactor technology in the production

and marketing of its first commercial product, ASTAFACTOR®), a nutraceutical and

source of natural astaxanthin. Natural astaxanthin, a carotenoid found in many

species of fish and seafood (it gives wild salmon its distinctive color), has

long been recognized as a valuable nutritional supplement. The Company's

development of the MGM has enabled it to produce astaxanthin for commercial

distribution cost and introduce SALMON ESSENTIALS™), a proprietary combination

of astaxanthin and Omega-3 fatty acids.

The

Company's business strategy is to exploit its leading position in microalgae

cultivation technology to expand the sales of ASTAFACTOR®) AND SALMON

ESSENTIALS™ while preserving margins. We also hope to develop and introduce

additional microalgae-based nutritional products to the marketplace in the

future.

We face

significant potential competition for ASTAFACTOR®). We expect that other

nutraceutical products that the Company may launch in the future will face

meaningful competition as well, although at present we are not aware of a

product that combines the same ingredients as SALMON ESSENTIALS™ in a single

product.

We do not

believe that any commercial entity has developed a photobioreactor that matches

the MGM's combination of large size, low cost and level of process control or

sustained performance for a wide variety of aquatic species, although a number

of other companies are developing closed environment production systems for

marine micro-organisms. We believe that competition in each of these areas may

increase significantly over time as alternatives to the Company's patented

technology are developed. For more information on our competition, see "Risk

Factors; Risks Related to Our Industry.”

Mera

Pharmaceuticals' patents and intellectual property include issued patents

relating to the MGM and general processes for cultivating microalgae in

photobioreactors. The Company believes that intellectual property relative to

aquatic organism biotechnology will become much more important, challenging and

complex in the future.

Government

regulation and product testing are strong factors in the markets for the

products we have developed and produced. Our products are subject to regulation

by the U.S. Food and Drug Administration or similar agencies in foreign

countries and may require extensive testing for safety and efficacy before being

released for sale.

The

Company currently manufactures its products at a five-acre research, development

and production facility at the Hawaii Ocean Science and Technology Business Park

in Kailua-Kona, Hawaii. The facility is ideally located for research and

development and the commercial production of microalgae. We have access to large

volumes of deep ocean water (used for temperature control) in a stable tropical

climate with plentiful sunlight, conditions that are well suited to microalgae

cultivation. Although Hawaii's distance from many markets increases certain

costs of operation, on balance there are few locations, domestic or

international, that are as well suited to our cultivation

processes.

In

addition to the production of our own products, the Company is also seeking new

research collaborations with other enterprises to demonstrate the economic

feasibility of producing valuable substances that they have identified in

microalgae. Such collaborations will be sought to expand the applications of

Mera's technology. We will also explore licensing opportunities for the

technology where that makes economic sense.

RATIONALE

FOR MICROALGAE AS A SOURCE OF COMMERCIAL PRODUCTS

Microalgae

represent approximately half of all plant species. Many of their characteristics

make them attractive for commercial production.

|

|

·

|

Fewer

than 5,000 out of the estimated total of 30,000 species are believed to

have been cultivated in the

laboratory

|

|

|

·

|

Fewer

than 1,000 species are believed to have been carefully investigated for

new substances

|

|

|

·

|

Fewer

than 10 species have been cultivated at commercial

scale

|

|

2)

|

DEMONSTRATED

SOURCE OF NEW SUBSTANCES

|

|

|

·

|

Several

hundred new bioactive substances have been discovered in the small number

of microalgae that have been researched to

date

|

|

3)

|

SOURCE

OF VALUABLE SUBSTANCES

|

|

|

·

|

Many

molecules derived from microalgae are already known to be valuable for use

as enzymes, pigments, vitamins, nutraceuticals, pharmaceuticals and the

like

|

|

|

·

|

Bioactive

compounds extracted from microalgae have substantial potential value as

pharmaceuticals

|

|

|

·

|

Growth

rates for microalgae species range from about 1 to 10 divisions per

day

|

|

|

·

|

Growth

rates for these plants are, in general, faster than any other

plants

|

|

5)

|

LOW

COST OF RAW MATERIALS

|

|

|

·

|

Water,

sunlight, fertilizer and carbon dioxide, the principal raw materials used

in cultivation, are plentiful and

economical

|

THE

COMPANY'S MGM TECHNOLOGY

FEATURES OF MGM TECHNOLOGY.

The key features of MGM technology are sterility, size (25,000 liters) and

enhanced control over virtually all environmental factors affecting growth rates

and metabolic activity, such as temperature, pH, nutrient mix and distribution,

light, pests and contaminants.

This

combination of size and control has been the goal of international research

efforts for the past several decades. The MGM has achieved that goal. Although

it is among the largest photobioreactors ever operated, the MGM's patented

technology allows a far greater degree of control of the growth environment than

has been possible in systems previously.

PROCESS CONTROL SYSTEMS - THE KEY TO

REPRODUCIBLE PERFORMANCE.

In order to take greatest advantage of the MGM

technology, we have developed proprietary, computerized process control systems

for the MGM that make it possible to conduct the following operations

automatically:

|

|

·

|

monitoring

of key production variables at intervals more frequent than one

minute;

|

|

|

·

|

data

archiving for comprehensive analysis of

system

|

|

|

·

|

performance;

automated control of all operations performed more than once

a

|

|

|

·

|

day

(both a process control improvement and labor cost

saving);

|

|

|

·

|

immediate

alarm system for any system component not operating within parameters;

and

|

|

|

·

|

automated

maintenance for hundreds of system components, reducing failures and

preventing contamination.

|

Increasing

control over processes has produced several benefits. Product quality and

consistency have gone up, the scale at which processes are controllable has

increased and the amount of capital and labor required to accomplish a given

amount of production has decreased. This combination of effects translates into

enhanced efficiency, which translates into lower cost per unit of production and

higher margins.

COMPETITIVE PRODUCTION

SYSTEMS.

We are not aware of any closed system photobioreactor that

compares favorably with the MGM.

There are

other systems that cultivate microalgae at larger than experimental scale.

However, we believe that the advantages of the MGM over these other systems

include size, versatility, cost-effectiveness and higher yields. We believe that

an important advantage of the MGM over any competing technology is the ability

to achieve a high degree of control over all critical environmental factors for

microalgae, except those species that proliferate under the most extreme

conditions. As a result, it can be used in efficiently cultivating hundreds,

even thousands, of microalgal species at commercial scale. We do not believe any

other large scale system has such flexibility and versatility, which are

important factors in the development of new products from a variety of

microalgal species.

PRODUCTS

FROM MICROALGAE

DESCRIPTION AND PROPERTIES.

Astaxanthin is a red-orange, carotenoid pigment. It is closely related to other

well-known carotenoids, such as beta-carotene, lutein and

zeaxanthin.

All of

these molecules are antioxidants, substances shown by research to protect

health, but astaxanthin is among the strongest. Some studies indicate that it is

ten times more potent than beta-carotene, and more than 500 times more potent

than vitamin E - another well known and commonly used antioxidant.

Astaxanthin

is one of the main pigments in aquatic animals. It gives the flesh of salmon its

characteristic color, for example. Yet, it is far more than a pigment.

Astaxanthin has been shown to perform many essential biological functions,

including:

|

|

·

|

protecting

against the harmful effects of UV

light;

|

|

|

·

|

enhancing

the immune response;

|

|

|

·

|

protecting

against the oxidation of essential polyunsaturated fatty

acids;

|

|

|

·

|

stimulating

pro-vitamin A activity and vision;

|

|

|

·

|

improving

reproductive capacity; and assisting in

communication.

|

In

species like salmon or shrimp, astaxanthin is essential to normal growth and

survival and has been attributed vitamin-like properties. Some of these unique

properties are also effective in mammals. Studies in human and animal models

suggest that astaxanthin may substantially improve human health by virtue of its

antioxidant properties, protecting vision, reducing inflammation (recently shown

to be a major factor in heart attacks) slowing neurodegenerative diseases and

preventing certain cancers.

THE ASTAFACTOR® MARKET.

We

believe that the market for ASTAFACTOR® is likely to expand over the next few

years. There is growing evidence in the scientific and medical literature that

astaxanthin contributes meaningfully to the general well-being of humans.

Although we face competition in this market, we believe that our technology will

give us significant cost and quality advantages over our competitors in our

effort to capture a significant share of this growing market.

Sales of

ASTAFACTOR(R) began in Hawaii in March, 2000. Our experience has shown that

effectively promoting retail sales of astaxanthin requires longer format

advertising than can be readily used in typical retail advertising. The Company

has maintained its focus in the Hawaiian market, which offers revenue potential

to help support the cost of broader retail distribution.

During

2004 the Company introduced an extension of its ASTAFACTOR®) line, Salmon

Essentials™. This product offers a unique combination of astaxanthin and Omega-3

fatty acids, the two most important nutritional components available from wild

salmon, which is widely recognized as one of nature's most healthful foods. This

product offers all of the health benefits associated with ASTAFACTOR®) and adds

to them the significant benefits of including Omega-3 fatty acids in your diet,

such as improved cardiac health. Omega-3s also help reduce inflammation, adding

to that important benefit of SALMON ESSENTIALS™.

We began

marketing SALMON ESSENTIALS™ during 2004, launching the product initially

through our Hawaiian retail distribution system. We have also made SALMON

ESSENTIALS™ available through our web site. The Company is contemplating a

number of strategies to expand the distribution of what we believe is a product

with significant potential.

|

(3)

|

PRODUCT

LINE EXPANSION

|

The

Company is currently evaluating product line extensions for its ASTAFACTOR® and

Kona Sea Salt™ products and is also contemplating exploring additional

microalgae sources for development of nutraceutical products.

We

believe that many more nutraceutical products could be developed from

microalgae, but they remain unexamined and unexploited because there has been no

feasible way to grow them at a large enough scale. The MGM opens a path to this

untapped resource by combining effective, reproducible control with commercial

scale production.

DEPENDENCE

ON KEY CUSTOMERS

Our

business depends on key relationships in Hawaii. Sales to our largest customer,

Longs Drugs, owned by CVS, continues to represent the largest, but

decreasing percentage of our product sales. Sales to various domestic

distributors have been slowly increasing as have internet sales.

OUR

STRATEGIES

Our

objective is to sustain Mera Pharmaceuticals' leadership in microalgae

cultivation technology and to identify, optimize and directly commercialize

high-value microalgae products. We have several strategies to achieve these

goals.

1) INCREASE SALES OF

NUTRACEUTICAL PRODUCTS.

The Company intends to increase sales of its

current products, ASTAFACTOR®, SALMON ESSENTIALS™ and KONE SEA SALT™, by

expanding distribution through a variety of sales channels. It appears that

awareness of the benefits of our products is growing in the marketplace, and

once the benefits of our products are more fully understood by the general

public, we will focus on entering national domestic retail chains with the

potential for delivering high sales volumes at attractive margins and efficient

distribution.

2) EXPAND STRATEGIC

ALLIANCES.

We intend to develop relationships with other companies who

have products that will benefit from utilizing our technology under license. We

believe that there is significant potential revenue associated with the

licensing of our technology to other companies or in performing contract work

for them utilizing our facilities or expanded facilities if

justified.

MANUFACTURING

Our Kona

facility has sufficient capacity to meet our current demand for

products. Ability to expand our production is sufficient to meet our

projected needs for the foreseeable future. Further expansion of the Kona

facility is feasible, if demand for our products justifies doing

so.

RESEARCH

AND DEVELOPMENT COSTS

Research

and development costs include salaries, development materials, plant and

equipment depreciation and costs associated with operating our five-acre

research and development/production facility. During the last fiscal year, the

Company has spent $324,383 versus $299,696 in the previous year on research and

development activities.

MARKETING

AND SALES

The

Company's marketing strategy for its products may vary depending on the specific

product being sold and its target market, but that strategy is generally built

on two fundamental tenets:

1. CREATE ALLIANCES WITH

EFFICIENT, HIGH-QUALITY DISTRIBUTORS IN KEY U.S. REGIONAL AND INTERNATIONAL

MARKETS AND SUPPORT THOSE DISTRIBUTORS WITH EFFECTIVE ADVERTISING AND PROMOTION

TO THE CONSUMER.

The Company currently markets ASTAFACTOR®, SALMON

ESSENTIALS™ and KONA SEA SALT™ to mass retail outlets in Hawaii through

distribution arrangements with established companies. We are also expanding our

efforts to distribute outside of Hawaii.

2. SELL ASTAFACTOR®,

SALMONESSENTIALS™ AND KONA SEA SALT™ DIRECTLY TO THE CONSUMER.

This

approach allows us to reach consumers throughout the domestic market at the most

attractive margins, since it eliminates distributor and retailer profits.

Web-based and specialty media promotion are also used to reinforce our marketing

efforts and product visibility to all consumers. We are building a customer data

base that will enhance our ability to reach regular customers with new products

as they are developed and come to market.

COMPETITION

The

Company believes that its proprietary technology and process control systems and

software give it a significant advantage relative to its competitors. However,

there are a number of companies that are engaged in efforts to develop

microalgae-based products that compete with ours, either directly or

indirectly.

We

believe that our original MGM technology was the first closed-system,

process-controlled photobioreactor to be operated at commercial scales larger

than 2,750 gallons (10,000 liters). We can now operate at a scale more than

twice that (25,000 liters). We are aware of only three other companies in the

world - Biotechna of Australia, Algatechnologies of Israel and AstaReal of

Hawaii - that claim to possess proprietary photobioreactor

technology.

COMPETITORS

FOR ASTAFACTOR®) There are various other producers of astaxanthin that compete

with ASTAFACTOR®, our nutraceutical astaxanthin product. Competition also comes

from non-producers who acquire raw materials from the producers for distribution

in the nutraceuticals market.

Potential

competitors include producers of the synthetic material as well. However, to our

knowledge neither BASF, a large German chemical company, nor Hoffman-LaRoche, a

large Swiss pharmaceutical company, both large global producers of synthetic

astaxanthin, has indicated an interest in this market.

Furthermore,

we believe that consumers of nutraceuticals prefer products from natural sources

to those from synthetic sources. We are aware of other companies that are

interested in or are actually marketing nutraceutical astaxanthin which use a

fermentation process. We believe our production process has cost or quality

advantages or both over those other companies.

PATENTS,

LICENSES AND PROPRIETARY TECHNOLOGY

We rely

upon a combination of patents, copyrights, trade secrets, know-how, continuing

technological innovation and licensing opportunities to develop and maintain our

competitive position. Our future prospects depend in part on our ability to

obtain patent protection for our products and processes. We need to preserve our

copyrights, trademarks and trade secrets. We also need to operate without

infringing the proprietary rights of third parties.

PATENTS.

We have been awarded

or have filed applications for patents relating to various processes, including,

but not limited to, the process and apparatus for the production of

photosynthetic microbes and the method of control of microorganism growth

processes. These patents are active in the United States and potentially other

countries. The original duration of these patents varied from fifteen to twenty

years from the date of filing or issuance, and the Company's current patents

will be active for five to nine years, provided the maintenance fees associated

with such patents are timely paid. The Company reassesses the value of each

patent it holds at the time maintenance fees are due, and in cases where

maintaining a patent is judged to be of no significant strategic value, we do

not renew the patent.

Other

companies may have filed and in the future are likely to file patent

applications that are similar or identical to ours. To determine the priority of

inventions, we may have to participate in interference proceedings declared by

the United States Patent and Trademark Office. Such proceedings could result in

substantial costs to us. We cannot ensure that any such third-party patent

application will not have priority over ours. Additionally, the laws of certain

foreign countries may not protect our patent and other intellectual property

rights to the same extent as the laws of the United States.

Our

future prospects also depend in part on our neither infringing on patents or

proprietary rights of third parties nor breaching any licenses that may relate

to our technologies and products. We cannot guarantee that we will not infringe

on the patents, licenses or other proprietary rights of third parties. We have

not conducted an exhaustive patent search, and we cannot ensure that patents do

not exist or could not be filed that would have a material adverse effect on our

ability to develop and market our products. There are many United States and

foreign patents and patent applications in our area of interest.

We

attempt to control the disclosure and use of our proprietary technology,

know-how and trade secrets under agreements with the parties involved. However,

we cannot ensure that others will honor all confidentiality agreements. We

cannot prevent others from independently developing similar or superior

technology, nor can we prevent disputes that could arise concerning the

ownership of intellectual property.

TRADEMARKS AND SERVICE MARKS.

The following trademarks and service marks have been registered or are claimed

marks that the Company has not registered but as to which it believes it has

established a common law right of use and as to which it has no information to

the contrary. The registered trademark on ASTAFACTOR® is valid through

March 2012, and the following other claimed marks that the Company believes

it has established a common law right of use are valid for the standard period

of duration, as provided in applicable common law:

SALMONESSENTIALS™

AQUAXAN®

MERA

PHARMACEUTICALS™

MERA

GROWTH MODULE ™ (MGM)

MERA

PROCESS CONTROL SYSTEM™ (MPCS)

MERA

REMOTE DATA WEB ACCESS™ (RDWA)

DRUGS

FROM THE SEA™

KONA SEA

SALT™

GOVERNMENT

REGULATION AND PRODUCT TESTING

Our

current and potential products and our manufacturing and research activities are

or may become subject to varying degrees of regulation by many government

authorities in the United States and other countries. Such regulatory

authorities could include the State of Hawaii Department of Health or

Agriculture Department, the FDA, and comparable authorities in foreign

countries. Each existing or potential microalgae product intended for human use

that we develop or market, either directly or through licensees or strategic

partners, may present unique regulatory problems and risks. Relevant regulations

depend on product type, use and method of manufacture. The FDA regulates, in

varying degrees and in different ways, dietary supplements, other food products,

medical devices and pharmaceutical products. Regulations govern manufacture,

testing, exporting, labeling and advertising.

Any

products we develop for use in human nutrition, or cosmetics could require that

we develop and adhere to Good Manufacturing Practices ("GMP"), as suggested by

the FDA, European standards and any other applicable standards mandated by

federal, state, local or foreign laws, regulations and policies. Our current

cultivation and processing facilities and procedures are not yet required to

comply with GMP or ISO standards, although our contract extraction and

encapsulation facilities must meet GMP standards, and they do. We believe we are

prepared to meet these requirements more broadly when necessary.

The

Company currently distributes ASTAFACTOR®, SALMON ESSENTIALS™ and KONE SEA SALT™

in the United States, and in certain foreign countries. We also hope to expand

our distribution internationally. Regulatory approval requirements vary by

country. We believe the approval process for our products in most countries will

come under their "natural" status and that it will be approved relatively

quickly; however, we can provide no assurances in this regard.

EMPLOYEES.

As of

October 31, 2009, the Company had five (5) full-time employees and

various part time help as needed. We consider relations with our employees to be

good. None of our employees is covered by a collective bargaining

agreement.

YOU

SHOULD CAREFULLY CONSIDER THE RISKS DESCRIBED BELOW, IN ADDITION TO ALL OTHER

INFORMATION INCLUDED IN THIS REPORT, BEFORE YOU DECIDE TO INVEST IN OUR COMMON

STOCK. IF ANY OF THE FOLLOWING RISKS OCCURS, OUR BUSINESS, FINANCIAL CONDITION

OR RESULTS OF OPERATIONS COULD BE MATERIALLY ADVERSELY AFFECTED. THE TRADING

PRICE OF OUR COMMON STOCK COULD DECLINE DUE TO ANY OF THE FOLLOWING RISKS OR

OTHERS NOT YET IDENTIFIED BY MANAGEMENT, AND YOU COULD LOSE ALL OR PART OF YOUR

INVESTMENT.

RISKS

RELATED TO OUR BUSINESS

WE

HAVE INCURRED SUBSTANTIAL OPERATING LOSSES AND EXPECT TO INCUR FUTURE LOSSES.

OUR FUTURE FINANCIAL RESULTS ARE UNCERTAIN, AND WE MAY NEVER BECOME A PROFITABLE

COMPANY.

From

September 16, 2002 (the date that we completed our reorganization

proceedings and adopted "fresh-start accounting") through October 31, 2009

we had an accumulated deficit of $8,111,859. Our losses to date are primarily

due to the costs of research and development, and the general and administrative

costs associated with our operations. We expect to continue to incur smaller

operating losses through at least fiscal year 2010. We expect to have

quarter-to-quarter and year-to-year fluctuations in revenues and expenses. As a

result, our losses may increase in the future, even if we achieve our revenue

goals, and some of those losses could be significant.

Should we

achieve profitability, we may be unable to sustain or increase profitability on

a quarterly or annual basis. Many factors could affect our ability to achieve

and maintain profitability, including:

|

|

·

|

our

ability to complete successfully the commercialization and production cost

optimization of our products;

|

|

|

·

|

our

ability to manage production costs and yield issues associated with

increased production of our

products;

|

|

|

·

|

the

progress of our research and development programs for developing other

microalgal products;

|

|

|

·

|

the

time and costs associated with obtaining regulatory approvals for our

products;

|

|

|

·

|

our

ability to protect our proprietary rights, or the expense of doing

so;

|

|

|

·

|

the

costs of filing, maintaining, protecting and enforcing our

patents;

|

|

|

·

|

competing

technological and market

developments;

|

|

|

·

|

changes

in our pricing policies or the pricing policies of our

competitors;

|

|

|

·

|

the

costs of commercializing and marketing our existing and potential

products; and

|

|

|

·

|

the

inability to achieve a level of sales of our products necessary to

generate sufficient revenues to cover research, development and operating

costs.

|

If our

revenues grow more slowly than we anticipate or if our operating expenses exceed

our expectations and cannot be reduced, our losses could continue beyond our

present expectations, and we may never become a profitable company.

WE

MAY BE UNABLE TO RAISE ADDITIONAL CAPITAL OR GENERATE THE CAPITAL NECESSARY

TO

SUPPORT OUR PLANNED LEVEL OF RESEARCH AND DEVELOPMENT ACTIVITIES AND TO

MANUFACTURE

AND MARKET OUR PRODUCTS.

We will

require expenditures to support our research and development activities and to

manufacture and market our products. Over the next twelve months, we project

expenditures of approximately $600,000 in operating capital, not including any

capital expenditures that may be necessary or desirable. Many factors will

determine our future capital requirements, including:

|

|

·

|

market

acceptance of our products;

|

|

|

·

|

our

ability to manufacture our products cost-effectively in quantities needed

to sustain growing sales of our ASTAFACTOR® and KONA SEA SALT™ line of

products;

|

|

|

·

|

the

extent and progress of our research and development

programs;

|

|

|

·

|

the

time and costs of obtaining regulatory clearances for some of our

products;

|

|

|

·

|

the

costs of filing, maintaining, protecting and enforcing patent

claims;

|

|

|

·

|

the

need to address competing technological and market

developments;

|

|

|

·

|

the

cost of developing and/or operating production facilities for our existing

and potential products; and

|

|

|

·

|

the

costs of commercializing our

products.

|

Revenue

from product sales and other sources pay some of our operating costs, but to

date that revenue has not been sufficient to cover our operating costs fully. We

are seeking investment from various sources to help sustain our operations until

we can increase revenues to the point that they can sustain our operations

indefinitely. However, additional financing may not be available on favorable

terms, if at all. If we do not have adequate funds, we may have to curtail

operations significantly. In addition, we may have to enter into unfavorable

agreements that could force us to relinquish certain technology or product

rights, including patent and other intellectual property rights. If we cannot

raise enough capital, then we may have to curtail production, limit our product

development activities, reduce marketing activities or delay other plans

intended to increase revenue and help us achieve profitability.

IF

WE CANNOT OVERCOME THE CHALLENGES OF PRODUCING MICROALGAE ON A COMMERCIAL SCALE,

WE MAY NOT ACHIEVE ECONOMIC PRODUCTION COSTS.

To be

successful, we must produce products at acceptable costs while ensuring that the

quantity and quality of our products comply with contractual and regulatory

requirements and regulations. Many factors complicate the production of

microalgal products, and they could limit production at any time. These

include:

|

|

·

|

microbial

contamination;

|

|

|

·

|

variability

in production cycle times due to technical, environmental and biological

factors; and

|

|

|

·

|

losses

of final product due to inefficient

processing.

|

We

currently have sufficient inventory to meet the foreseeable requirements of our

existing customers. However, we are engaged in efforts to increase sales in

order to achieve profitability, potentially beyond the capacity of our existing

facility to produce. We have prepared to meet that increased demand, should it

occur, by acquiring additional space at our Kona, Hawaii facility.

IF

THE DEMAND FOR NATURAL ASTAXANTHIN OR OUR OTHER PRODUCTS EXCEEEDS OUR CURRENT

PRODUCTION CAPABILITIES, AND IF WE ARE UNABLE TO EXPAND OUR PRODUCTION CAPACITY

IN A TIMELY MANNER, WE MAY EXPERIENCE SIGNIFICANT FINANCIAL, TECHNICAL AND

COMMERCIAL CHALLENGES.

The

capacity of our existing production facility in Hawaii is sufficient to

meet

current demand

for our products. However, demand for our natural astaxanthin and other products

may eventually exceed the current capacity of our Hawaiian production facility.

To address this capacity question, we have initiated efforts to increase our

production efficiency and to prepare for expansion of our Hawaiian facility, if

needed. However, our efforts are focused on generating a level of sales that

would make it difficult to meet our total demand from our Hawaiian facility,

especially if we develop additional products. We believe that our inventory plus

our existing production capacity is sufficient to meet demand for the

foreseeable future. In the event that sales increase to a level that we cannot

meet with our existing capacity, we have planned for the expansion of our

Hawaiian facility. If we are unable to expand our current production facility,

we may be unable to meet demand for product and could lose the opportunity to

increase our revenues. We could also lose customers, both current and potential,

who may not do business with us absent an assurance of the ability to deliver

product in sufficient quantities.

OUR

CUSTOMER BASE IS CONCENTRATED AMONG RELATIVELY FEW CUSTOMERS, AND THE LOSS OF

ANY OF THESE CUSTOMERS WOULD MATERIALLY ADVERSELY AFFECT OUR

REVENUES.

Our

business currently depends on key distribution relationships in Hawaii.

These customers

currently purchase approximately 30% of the natural products we sell,

with the remainder being sold to smaller retail accounts, directly to consumers

or internationally. If we lose one or more of these customers, or if they do not

continue buying our products at the current and anticipated purchase levels,

then our revenues could decrease. In addition, the loss of one or more of these

customers may adversely affect our reputation, and we could have difficulty

attracting new customers as a result.

IF

WE FAIL TO ATTRACT AND RETAIN KEY PERSONNEL WE WILL BE UNABLE TO EXECUTE OUR

BUSINESS PLAN, AND OUR BUSINESS WILL SUFFER.

Our

success depends on the continued efforts of the principal members of our

management team. The Company presently has the key members of that team that it

needs to retain to execute its plans fully. Success in doing so cannot be

assured.

OUR

BUSINESS WILL NOT OPERATE EFFICIENTLY AND OUR RESULTS OF OPERATIONS WILL BE

NEGATIVELY AFFECTED IF WE ARE UNABLE TO MANAGE OUR GROWTH

EFFECTIVELY.

Until

2002 we focused almost exclusively on product research and technology

development. As we moved toward commercial production of microalgal products we

had to initiate or expand many activities, including outsourcing, customer

relations, engineering, construction, recruiting and training. During this

transition, the size of our organization increased rapidly. During the Company's

reorganization, the size of our organization decreased again. We expanded our

employee base nominally during fiscal year 2009 and expect to rationally expand

during fiscal year 2010 in both sales staff and production assuming revenues

expand with increased demand for our products. If revenues do not increase, we

may not have the financial resources needed to sustain operations.

We expect

demands on our financial and management control systems to increase this year.

If we fail to upgrade our financial and management control systems, or if we

encounter difficulties during upgrades of these systems, then we may not be able

to manage our human and financial resources effectively. Such ineffectiveness

could make it difficult to retain or attract employees and could directly or

indirectly create unnecessary expenses or lead to incorrect decisions by

management.

AS

WE EXPAND OUR PRODUCT LINE AND ATTEMPT TO PENETRATE ADDITIONAL MARKETS, WE MAY

FACE SIGNIFICANT CHALLENGES TO SUCCESS.

We are

exploring expanding our product lines. The success of our

product lines will

depend on our ability to implement our marketing strategy and comply with the

standards of Good Manufacturing Practice, or GMP, as and when applicable. We

believe the prospects for nutraceutical products will depend, in the short

term, on product quality and education of consumers regarding its benefits. Our

ability to penetrate new markets for our natural astaxanthin products will, we

believe, depend strongly on regulatory approval in several major markets within

and outside the United States. We expect the success of our products to depend

primarily on our ability to develop and market these new products.

We cannot

assure successful development of any potential products, nor can we guarantee

market acceptance of any of our products, existing or future. We have limited

marketing experience in nutraceutical markets. We have eight years of experience

in electronic marketing and direct retail sales. We cannot assure you that we or

our consultants or contractors will be successful in our marketing efforts, nor

can we prevent them from competing with us or assisting our competitors. If we

are unable to develop or commercialize any of our product lines successfully,

then our revenues will fail to grow.

OUR

PRODUCTS AND PRODUCTION ACTIVITIES ARE SUBJECT TO GOVERNMENT REGULATION AND

ACTION, WHICH ARE SUBJECT TO CHANGE.

We are

affected by changes in or the imposition of governmental regulations and

actions, including: (i)

new laws, regulations and judicial decisions related to the production,

marketing and sale of nutraceutical products, (ii) changes in the United States

Food and Drug Administration and foreign regulatory approval processes that may

delay or prevent the approval of new products and result in lost market

opportunity, (iii) new laws, regulations and judicial decisions affecting

pricing or marketing of our products and (iv) changes in the tax laws relating

to Mera Pharmaceuticals' operations.

WE

MAY BE UNABLE TO PROTECT OR ENFORCE OUR INTELLECTUAL PROPERTY RIGHTS

ADEQUATELY,

AND OUR EFFORTS TO DO SO COULD BE TIME CONSUMING AND EXPENSIVE AND COULD DIVERT

MANAGEMENT ATTENTION FROM EXECUTING OUR BUSINESS STRATEGY.

We regard

the protection of our patents, copyrights, trade secrets and know-how

(collectively

intellectual property) as critical to our success. We rely on a combination of

patent, copyright and trade secret laws and contractual restrictions to protect

our intellectual property and maintain our competitive position. Our future

prospects depend in part on our ability to protect our intellectual property

while operating without infringing the intellectual property rights of third

parties.

We may be

unable to develop any additional patentable technologies. We cannot be certain

that any patents issued to us or available to us through a license arrangement

will establish the means to produce or provide us with any competitive advantage

for any product or products. Third parties could challenge our patents or could

obtain patents that have a material adverse effect on our ability to do business

efficiently and effectively.

The

patent positions of nutraceutical, pharmaceutical, biopharmaceutical and

biotechnology companies, including ours, are generally uncertain and involve

complex legal and factual questions. Patent law continues to evolve in the scope

of claims in the technology area in which we operate. Therefore, the degree of

future protection for our proprietary rights is uncertain. We cannot guarantee

that others will not independently develop similar or alternative technologies.

Other parties may duplicate our technologies, or, if patents are issued to us,

they may design around those patented technologies. Other parties may have filed

or could file patent applications that are similar or identical to some of ours.

These patent applications could have priority over ours. To determine the

priority of inventions, we may have to participate in interference proceedings

declared by the United States Patent and Trademark Office, which could be very

costly. In addition, the laws of some foreign countries may not protect our

patents and other intellectual property rights to the same extent as the laws of

the United States.

We could

incur substantial costs in litigation if we need to defend ourselves against

patent infringement claims brought by third parties, or if we choose to initiate

claims against others. We have in the past, and we may in the future, be

required to dedicate significant management time and financial resources to

prosecute or defend infringement actions. In addition, a finding of

non-infringement or declaration of invalidity of our patents could reduce or

eliminate the exclusivity of our proprietary technology. Present and potential

collaborators may terminate or decide not to enter into relationships with us if

our intellectual property position is weakened. In addition, a finding of

non-infringement or declaration of invalidity of our patents could reduce our

ability to obtain future financing.

There

could be significant litigation in our industry regarding patent and other

intellectual property rights. For example, third parties may bring infringement

or other claims against us for using intellectual property that we internally

developed or license from third parties. In addition, although nondisclosure

agreements generally control the disclosure and use of our proprietary

technology, know-how and trade secrets, we cannot guarantee that all

confidentiality agreements will be honored or that our proprietary technology,

know-how and trade secrets will not be disseminated, or that any party

responsible for doing so will be able to compensate us adequately for such

loss.

We may

not prevail in the prosecution or defense of any action, nor can we predict

whether third parties will license necessary intellectual property rights to us

on commercially acceptable terms, if at all. Any of these outcomes could be very

costly and could diminish our ability to develop and commercialize future

products.

OUR

PRODUCTION CAPABILITY IS HIGHLY DEPENDENT ON ENVIRONMENTAL AND CLIMATIC FACTORS

BEYOND OUR CONTROL.

All of

our current production capacity is located at a single facility in Kona, Hawaii.

We currently have an ample inventory to meet our foreseeable demand, but any

future event that causes a long-term disruption in production at our facility

could significantly impair our ability to meet customer demand. These events

could include fires, volcanic eruptions, earthquakes, tidal waves, hurricanes or

other natural disasters. In addition, consistent sunlight, high ambient

temperatures and an ample supply of fresh water are necessary for microalgal

growth. If we experience any significant or unusual change in climate, or should

our water supplies be threatened by microbial contamination we cannot control,

there could be an adverse impact on our production. If we cease production for

any significant period, the success of our business would be threatened from a

resulting loss of customers, revenues and valuable employees.

CURRENCY

FLUCTUATIONS AND DIFFERENT STANDARDS, REGULATIONS AND LAWS RELATING TO

INTERNATIONAL OPERATIONS MAY ADVERSELY AFFECT OUR RESULTS OF

OPERATIONS.

We expect

to sell our products on a global scale due to projected international market

demand. International business is generally more difficult than domestic

business and can create additional costs and delays not associated with business

conducted solely within the United States. Factors related to doing business

internationally that could impact us include: foreign government controls and

regulations, economic conditions, currency fluctuations, duties and taxes,

political and economic instability or unrest, imposition of or increases in

tariffs, disruptions or delays in shipments and other trade restrictions. These

factors, among others, can all lead to interference with or increased costs of

operation and the ability to sell products in international markets. If any such

factors were to render the conduct of business in a particular country

undesirable or impracticable, there could be a material adverse effect on our

business, our financial condition and the results of operations. There can be no

assurance that our products or marketing efforts will be successful in foreign

markets.

In

addition, fluctuations in currency exchange rates could make our products more

expensive in some countries, resulting in the loss of customers in those

markets.

WE

MAY BE SUBJECT TO PRODUCT LIABILITY LAWSUITS, AND OUR INSURANCE MAY BE

INADEQUATE TO COVER DAMAGES.

Clinical

trials or marketing of any of our current or potential products may expose us to

liability claims arising from the use of these products. Even the most thorough

of clinical trials could fail to detect a significant side effect associated

with long-term use of a product, and it is possible that liabilities will arise

even after our products receive any required regulatory approvals. Even if such

claims are not well-founded, defending them will be very costly and consume

substantial management attention and energy. We cannot ensure that our current

product liability insurance, together with indemnification rights under our

existing or future licenses and collaborative arrangements, will be adequate to

protect us against any claims and resulting liabilities. As we expand our

business, we may be unable to obtain additional insurance on commercially

reasonable terms. We could suffer harm to our financial condition and our

reputation if a product liability claim or recall exceeds the limits of our

insurance coverage.

BECAUSE

OUR PRINCIPAL STOCKHOLDERS HAVE SIGNIFICANT CONTROL OF OUR MANAGEMENT AND

AFFAIRS, THESE STOCKHOLDERS MAY BE ABLE TO CONTROL US AND ALSO PREVENT

POTENTIALLY BENEFICIAL ACQUISITIONS OF OUR COMPANY BY OTHERS.

As of

October 31, 2009, our current directors and executive officers and family

and related entities, as a group, beneficially owned approximately 100,100,000

of the approximately 548,000,000 shares of our common stock outstanding as of

October 31, 2009. As a result, our officers and directors may be able to

exert considerable influence over the actions of the Board of Directors and

matters requiring approval of our stockholders. This concentration of ownership

could delay or prevent a change in control and may adversely affect the ability

of other stockholders to adopt a position in opposition to these directors and

officers. Our principal stockholders may have interests that differ from our

other stockholders, particularly in the context of potentially beneficial

acquisitions of our Company by others, and they may legitimately vote as

stockholders in a manner that protects their interests.

RISKS

RELATED TO OUR INDUSTRY

IF

WE FAIL TO COMPETE EFFECTIVELY AGAINST LARGER, MORE ESTABLISHED COMPANIES

WITH

GREATER RESOURCES, OUR BUSINESS WOULD SUFFER.

Competition

in the nutraceutical market is intense. Factors affecting competition

include financial resources, research and development capabilities and

manufacturing and marketing experience and resources.

Our

nutraceutical astaxanthin products will compete directly with the products of

several companies that sell a similar nutraceutical product. At least three

companies that we are aware of have a product like ours. We expect that our

nutraceutical astaxanthin products will compete on the basis of product quality,

price, and efficiencies derived from our intellectual property and an effective

marketing strategy. However, if our competitors develop a proprietary position

that inhibits our ability to compete, or if our marketing strategy is not

successful, then our revenues may not increase.

There are

various companies using microalgae cultivation technology processes that compete

with our processes. We are aware of two U.S. companies, Martek of Maryland and

Omega-Tech of Colorado, that produce commercial quantities of microalgae using

modified fermentation processes. We are also aware of one company, Cell Tech of

Oregon, which harvests microalgae from natural environmental sources. There are

three other companies in the world - Biotechna of Australia, AlgaTechnologies of

Israel and AstaReal of Hawaii - that claim to possess proprietary

photobioreactor technology and use it for commercial purposes. While there are

many other photobioreactors in operation besides those, to our knowledge, they

are all operated by universities or research institutes and are not used for

commercial purposes. It is possible that competing photobioreactor technologies

that could adversely affect our perceived technical and competitive advantages

already exist or may emerge in the future.

We also

anticipate that the competition to develop microalgal-based products other than

natural astaxanthin will increase. We expect competitors to include major

pharmaceutical, food processing, chemical and specialized biotechnology

companies. Many of these companies will have financial, technical and marketing

resources significantly greater than ours. There are also other emerging marine

biotechnology companies that could form collaborations with large established

companies to support research, development and commercialization of products

that may compete with our current and future products. Also, academic

institutions, governmental agencies and other public and private research

organizations are conducting research activities and seeking patent protection

for microalgal products and may commercialize products that compete with ours on

their own or through joint ventures. In addition, there may be technologies we

are unaware of, or technologies that may be developed in the future, that could

adversely affect our perceived technical and competitive advantage.

INCREASED

COMPETITION MAY SIGNIFICANTLY REDUCE THE MARKET PRICE OF NATURAL

ASTAXANTHIN.

Astaxanthin

can be produced either naturally from Haematococcus pluvialis, as we do, from

yeast by fermentation, as Igene Biotechnology, Inc. does, or through synthesis

of chemical compounds. We are not aware that synthetic astaxanthin is approved

for direct human consumption in any jurisdiction, although the FDA approved the

Hoffman-LaRoche, Ltd. synthetic astaxanthin product as a food additive in fish

feed in 1995. The Igene yeast-based product is also not approved for regular

human consumption. We believe that the cost of producing synthetic astaxanthin

is significantly lower than that for natural astaxanthin. We are not able to

determine how production costs for the yeast-based product compares with ours.

If we succeed in commercializing natural astaxanthin to the extent we project,

producers of yeast-based and synthetic astaxanthin may increase their efforts to

obtain approval of their product for human consumption. Studies have shown that

natural astaxanthin is more effective than synthetic astaxanthin when used with

various fish and shellfish populations. However, we have not determined that to

be the case in human applications. The introduction of yeast-based or synthetic

astaxanthin into the human nutraceutical marketplace could adversely affect the

price at which we sell our product and the market share that we can obtain.

While we believe that there are substantial hurdles to the approval of

yeast-based and synthetic astaxanthin for human consumption in the U.S. and

other major markets, we cannot be certain that such approval will not occur. A

single producer, Hoffman-LaRoche, Inc., currently dominates the synthetic

astaxanthin market. Hoffman-LaRoche has maintained the market price of its

synthetic astaxanthin, which is derived from petrochemicals, at approximately

$1,800 - $2,500 per kilogram. That is below the price at which we would be able

to sell astaxanthin in comparable form.

IF

WE ARE UNABLE TO COMPLY WITH GOVERNMENT REGULATION OF OUR PRODUCTS AND

PRODUCTION

ACTIVITIES, WE MAY BE FORCED TO DISCONTINUE PRODUCTION OF CURRENT OR FUTURE

PRODUCTS.

We are

subject to federal, state, local and foreign laws and regulations governing our

products and production activities. This makes us vulnerable to: (i) the

imposition of new laws, regulations and judicial decisions related to

pharmaceutical and nutraceutical products, (ii) changes in the United States

Food and Drug Administration and foreign regulatory approval processes that may

delay or prevent the approval of new products and result in lost market

opportunity, (iii) delays in the receipt of or the inability to obtain required

approvals, (iv) new laws, regulations and judicial decisions affecting pricing

or marketing of pharmaceutical and nutraceutical products, (v) the suspension or

revocation of the authority necessary for manufacture, marketing or sale of our

products, (vi) the imposition of additional or different regulatory

requirements, such as those affecting labeling, (vii) seizure or recall of

products, and (viii) the failure to obtain, the imposition of limitations on the

use of, or the loss of patent and other intellectual property rights. While we

do not consider our products to be "herbal" supplements (i.e., products that are

made from drying and grinding entire plant parts), increased regulatory scrutiny

of herbal products as the result of health issues (e.g., with ephedra) may also

lead to more stringent regulation of our products.

Each

existing or potential product that we develop, produce, market or license

presents unique regulatory problems and risks. Relevant regulations depend on

product type, use and method of manufacture. The FDA regulates, in varying

degrees and in different ways, dietary supplements, other food products, medical

devices and pharmaceutical products. Regulations govern manufacture, testing,

exportation and labeling, while the Federal Trade Commission (FTC) regulates

advertising.

We are or

may become subject to other federal, state and foreign laws, regulations and

policies with respect to labeling of products, importation of organisms and

occupational safety, among others. Federal, state and foreign laws, regulations

and policies are always subject to change and depend heavily on administrative

policies and interpretations. We cannot ensure that any of our products will

satisfy applicable regulatory requirements. Changes could occur in federal,

state and foreign laws, regulations and policies and, particularly with respect

to the FDA or other such regulatory bodies, such changes could be retroactive.

Such changes could have a material adverse effect on our business, financial

condition, results of operations and relationships with corporate

partners.

Nutraceutical

products that we develop will be viewed as human dietary supplements. The FDA

requires pre-market clearance in the United States, as do other countries where

these nutraceutical products are marketed, if they are intended for human

consumption. The process of obtaining FDA clearance for either a food additive

or a human dietary supplement can be expensive and time consuming, although

significantly less expensive than the process for obtaining clearances for a new

pharmaceutical. With natural products such as ours there is often only a brief

and inexpensive waiting period before marketing of a nutraceutical can begin.

Extensive information is required on the toxicity of the additive, including

carcinogenicity studies and other animal testing. FDA clearance to market

dietary supplements is obtained by notifying the FDA in writing of the intention

to market a certain product and providing supporting documentation regarding

toxicity. If the FDA does not object within a specified period of time, approval

is deemed granted.

Mera's

corporate predecessor received FDA clearance for the ASTAFACTOR® in early 2000.

We similarly notified the FDA of our intention to market Salmon Essentials™ in

2004, without objection. While we believe that the natural products on which we

are focused will be subject to few objections in this approval process, we

cannot ensure that any of our future products, on which we may have expended

substantial development effort, will be cleared by the FDA on a timely basis, if

at all.

The

ASTAFACTOR® AND SALMON ESSENTIALS™ our nutraceutical astaxanthin products are

being distributed internationally already and are likely to be distributed in

others. Regulatory approvals in foreign markets vary by country. We believe the

approval process for these products will generally come under their "natural

product" status and be approved relatively quickly. However, we can provide no

assurances in this regard.

THE

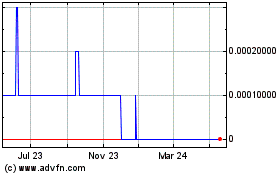

PRICE OF OUR COMMON STOCK MAY BE HIGHLY VOLATILE.

The

trading price of our common stock has been, and is likely to continue to be,

highly volatile. We could be subject to wide fluctuations in price in response

to various factors, many of which are beyond our control,

including:

|

|

·

|

announcements

of technological innovations or new commercial products by us or our

competitors;

|

|

|

·

|

developments

concerning proprietary rights, including patents, by us or our

competitors;

|

|

|

·

|

publicity

regarding actual or potential benefits or drawbacks relating to products

under development by us or our

competitors;

|

|

|

·

|

conditions

or trends in the life sciences, nutraceutical or pharmaceutical

markets;

|

|

|

·

|

changes

in the market valuations of biotechnology and life sciences companies in

general; and

|

|

|

·

|

general

regulatory developments affecting our products in both the United States

and foreign countries.

|

In

addition, technology companies have experienced extreme price and volume

fluctuations that have often been unrelated or disproportionate to the operating

performance of those companies. There has been particular volatility in the

market prices of securities of life science companies. These broad market and

industry factors may seriously harm the market price of our common stock,

regardless of our operating performance.

RISKS

RELATED TO THE SECURITIES MARKETS AND OUR COMMON STOCK

OUR

COMMON STOCK IS TRADED ON THE PINK-SHEET MARKET, WHICH MAY MAKE THE STOCK MORE

DIFFICULT TO TRADE ON THE OPEN MARKET.

Our

common stock is currently traded in the PINK-SHEET market. PINK-SHEET markets

are generally more difficult to trade than those on the Nasdaq National Market,

the Nasdaq Small Cap Market or the major stock exchanges. Since the initial

public offering of our common stock in January 1989, the average daily

trading volume of our common stock has been relatively low. We cannot ensure

that a more active public trading market will ever develop for our common stock.

In addition, accurate price quotations can be difficult to obtain and price

volatility is common for companies whose securities trade on the

PINK-SHEETS.

THE

SALE OF A SUBSTANTIAL NUMBER OF SHARES OF OUR COMMON STOCK BY STOCKHOLDERS COULD

CAUSE THE MARKET PRICE OF OUR COMMON STOCK TO DECLINE.

As of

October 31, 2009 we had 547,759,915 shares of common stock outstanding. Of

these shares, approximately 193,000,000 have either been registered under the

Securities Act of 1933, as amended (the "Securities Act"), are freely tradable

without volume limitations under Rule 144 of the Securities Act or are

exempt from registration under 11 U.S.C. 1145 as a result of the reorganization

of our predecessor issuer, Aquasearch, Inc.

We cannot

predict the effect, if any, that sales of shares of our common stock or the

availability of these shares being offered for sale will have on prevailing

market prices. However, substantial amounts of our common stock were sold in the

public market, to the point where raising capital has become extremely

difficult.

We will

need additional funding for capital expenditures and operating capital. If we

raise additional funds by selling equity securities, the share ownership of our

existing investors would be diluted. In addition, new equity purchasers may

obtain rights, preferences or privileges that are superior to those of our

existing stockholders and most likely demand a major reverse stock split in

order to clean up the capital structure. This would allow for

potential additional add on investments.

THE

ABILITY OF OUR BOARD OF DIRECTORS TO ISSUE PREFERRED STOCK COULD ADVERSELY

AFFECT THE INTERESTS OF OUR STOCKHOLDERS.

Our

Certificate of Incorporation authorizes the issuance of up to 10,000 shares of

"blank check" preferred stock, of which only slightly more than 1,000 have been

issued to date. Our Board of Directors has the power to determine all

designations, rights, preferences, privileges and restrictions of this preferred

stock. In addition, our Board of Directors is not required to obtain stockholder

approval to issue preferred stock with dividend, liquidation, conversion, voting

or other rights that could adversely affect the voting power or other rights of

the holders of our common stock. The Board of Directors could issue the

preferred stock in order to raise needed capital, or to discourage, delay or

prevent a change in control of our Company, even if a change of control would be

beneficial to our stockholders.

Our

research, development and production facilities are located in the Hawaii Ocean

Science and Technology (HOST) Business Park in Kailua-Kona, Hawaii. Our facility

currently consists of approximately five acres containing a number of MGMs,

finishing ponds, a processing facility, several laboratories, administrative

offices and additional space for production and research and development. All

our products are currently produced at this facility.

We

currently occupy this facility on a long term lease basis of 30 years with rents

increases renegotiated every five (5) years.

|

ITEM 3.

|

LEGAL

PROCEEDINGS.

|

The

Company is not currently a party to any pending legal proceedings, nor is any of

its property the subject of a pending legal proceeding.

|

ITEM 4.

|

SUBMISSION

OF MATTERS TO A VOTE OF SECURITY

HOLDERS.

|

No

matters were submitted to matters to a vote of security holders during the

fourth quarter of our 2009 fiscal year.

PART II

|

ITEM 5.

|

MARKET

FOR REGISTRANT’S COMMON EQUITY, RELATED STOCKHOLDER MATTERS AND ISSUER

PURCHASES OF EQUITY SECURITIES.

|

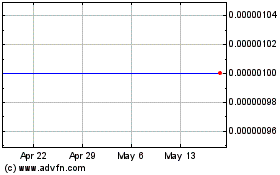

MARKET

FOR COMMON EQUITY AND RELATED STOCKHOLDER MATTERS

Our

common stock is traded in the over-the-counter market on the NASD Pink Sheets.

Symbol: "MRPI"). The following table shows the last sale price of the Company’s

stock sale as of October 31, 2009. as reported by financial reporting

services. This quotation is believed to represent inter-dealer quotations

without adjustment for retail mark-up, mark-down or commissions, and may not

represent actual transactions.

|

|

|

|

|

PERIOD

|

|

CLOSING

PRICE

|

|

FISCAL

2009

|

|

$ 0.005

|

As of

October 31, 2009, we had approximately 1,246 record holders of our

547,769,915 outstanding shares of common stock.

SECURITIES

AUTHORIZED FOR ISSUANCE UNDER EQUITY COMPENSATION PLANS

In

November 2004 the Board of Directors rescinded the previously adopted 2003

Stock Option Plan and adopted in its place the 2004 Stock Option Plan. That plan

authorizes the issuance of options to purchase up to 60,000,000 shares of the

Company's common stock. The Board of Directors granted options to purchase

approximately, 48,000,000 shares of stock, with vesting credit having been given

for past service to the company dating back to the effective date of our

reorganization. As of October 31, 2009, 12,430,000 of the options had