The leader of collaborative robotics continues

to blaze the trail in the cobot welding landscape, featuring new

advanced welding solutions for multi-axis, coordinated welding. New

cobot capabilities will also be showcased in extended reach and

portability applications, and in tasks such as laser restoration,

finishing, and press brake tending.

The line between traditional automation and collaborative robots

continues to grey as cobots take on more advanced welding tasks.

Since Universal Robots (UR) introduced North America’s first cobot

welder at FABTECH 2017, cobot welding has come a long way in a

short time.

This press release features multimedia. View

the full release here:

https://www.businesswire.com/news/home/20241011728383/en/

FABTECH 2024 in Orlando will be the

launchpad for a wide range of new cobot-powered fabricating and

welding technologies (Photo: Business Wire)

“UR cobots started out predominantly in air-cooled MIG welding

solutions placed on carts,” says Will Healy III, global industry

leader of welding at Universal Robots. “Now we see cobots take on

heavier duty and more advanced tasks such as TIG, laser, and spot

welding, along with plasma- and oxyfuel cutting.”

At Universal Robots’ FABTECH booth #4755, attendees will also

witness UR cobots ‘going beyond the cart,’ expanding the work

envelope. The show is the launchpad for dual-axis cobot welding

with coordinated motion through the cobot’s own controller. “Having

the cobot sync up with a rotary positioner or a linear rail, timing

it within milliseconds, means our customers can now weld parts they

normally couldn’t weld efficiently because they’d either have to

stop and manually move the part, or weld it at two different

times,” explains Healy.

A FABTECH first

The new capabilities are possible through UR’s new MotionPlus

package that enables UR’s welding partners to add dual-axis

coordinated motion capabilities to their own solutions. “To our

knowledge, this is the first time multi-axis cobot welding with

coordinated motion is showcased in North America,” says Healy.

Vectis Automation is one of the first UR partners to leverage

MotionPlus, launching the RevoTM Dual Axis system at FABTECH. The

new multi-axis positioning method can tackle more complex

multi-faceted parts and excel in situations where the fabricator

needs to get parts in position relative to gravity. Vectis will

also showcase QuickTeach and AI Path Optimization; QuickTeach

allows the cobot champion to teach points and optimize paths right

at the torch. AI Path Optimization applies user-defined work

angles, push/pull angles, and smoothed corner transitions to the

weld path - ensuring the weld is always created according to the

procedure specifications.

THG Automation will demonstrate multi-axis welding for the first

time as well, their THG Multi-motion features a dual-axis skyhook

with a part welded by a UR cobot mounted on a rail, all working in

unison. THG is also launching the THG-Multi-Op; two all-in-one

systems, one for MIG/TIG and one for cutting and welding, each

system has a tool changer that allows the operator to easily switch

between applications. Other new THG products at the show include a

laser welding system and a new mobile base that gives the user

flexibility to bring the system up to unusual sized parts.

PolyScope X redefines automation software

Having pioneered ease-of-use in cobot welding with the

innovative Beacon-teaching app, Hirebotics is one of the first UR

partners to leverage UR’s new PolyScope X platform, implementing

Beacon on the UR cobot’s teach pendant in addition to iOS, Android,

and any web-based device. Welders can now get instant in-app

support through the UR teach pendant, watch instructional videos,

and teach the cobot even complex welds in minutes. New advanced

Hirebotics cobot welding features include Enhanced Stitch Welding;

delivering the ability to stitch weld through complex paths and

Fine Tune; allowing precise adjustments in torch angles and weld

points, making it accessible for welders to optimize their

work.

Cobot welding on the move

“Leaping off of the cart entirely, the lightweight and easily

redeployable UR cobot is expanding onto new production floors

through cobot portability,” shares Healy. “With portable cobots,

welders in industries left out of automation like ship building and

construction now have access to a powerful tool to improve

productivity and eliminate boring repetitive work. Welders no

longer need to be contortionists bending into uncomfortable

positions to reach the joint for long hours each day.”

New innovative deployment of cobot welders includes the

Inrotech-Crawler making its FABTECH debut, featuring UR’s smallest

UR3 cobot placed on a carriage running on a flexible rail system

fixed to the substrate. The Inrotech-Crawler specializes in

butt-weld connections and multi-pass welding, regardless of the

shape or orientation. The robot continuously adjusts the welding

parameters according to its changing position (e.g. around a

pipe).

Another mobile cobot welder making a premiere at FABTECH is

Hyundai Welding’s portable cobot welding system. Hyundai Welding

has worked with the world’s largest and most advanced shipyards to

develop an agile solution addressing the tight working environments

in welding sections, especially inside-block welding of the ship’s

hull.

Cobots in press brake tending, finishing, and laser

restoration

Welding is not the only task expertly handled by cobots at

FABTECH. Alongside demos from Hirebotics, and Vectis Automation,

UR’s own booth features the following partner solutions:

The robotic machine tending system AutoTend from Mid Atlantic

Machinery, a press brake integration solution featuring a UR10e

cobot. AutoTend will bend a candy dish part from type 304 stainless

steel. The demo will showcase Mid Atlantic’s patented rotary

end-of-arm tooling while demonstrating the ability of the cobot to

bend complex parts while interacting directly with the press brake

touch screen control.

The Smart Finishing Workcell from Cohesive Robotics, a

game-changer for automated surface finishing tasks. At the show,

Cohesive Robotics will demonstrate autonomous scanning and

on-the-fly programming of a UR cobot to simulate various finishing

processes in the booth. Designed for high-mix manufacturing

operations, the work cell leverages machine vision and AI to

perform common material removal and surface finishing processes on

nearly any part, of any quantity, and with no programming

required.

Advanced Laser Restoration will be showcasing the next

generation of laser cleaning technology, highlighting the seamless

integration of advanced laser cleaning systems with robotic

automation. By pairing laser cleaning technology with the agility

of Universal Robots' systems, Advanced Laser Restoration automates

surface preparation tasks such as rust and coating removal with

pinpoint accuracy, reducing downtime and enhancing

productivity.

For attendees looking for a guided, insightful introduction to

the many new fabricating applications and solutions powered by UR

cobots, Universal Robots is hosting Cobot Walks at FABTECH for the

first time. The focused tour introduces participants to live

demonstrations, expert insights, future trends, networking

opportunities, and interactive Q&As.

Download images: Here

About Universal Robots

Universal Robots is a global leader in collaborative robotics

(cobots), used across a wide range of industries. Our mission is

simple: Automation for anyone. Anywhere. With over 90,000 cobots

sold worldwide, our user-friendly platform is supported by

intuitive PolyScope software, award-winning training, comprehensive

services, and the world’s largest cobot ecosystem, delivering

innovation and choice to our customers. Universal Robots is part of

Teradyne Robotics, a division of Teradyne (NASDAQ:TER), a leading

supplier of automatic test equipment and advanced robotics

technology.

View source

version on businesswire.com: https://www.businesswire.com/news/home/20241011728383/en/

Media contact: Mette McCall, McCall Media

mette@mccallmedia.net 251-278-9847

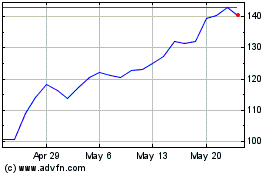

Teradyne (NASDAQ:TER)

Historical Stock Chart

From Oct 2024 to Nov 2024

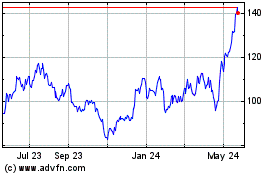

Teradyne (NASDAQ:TER)

Historical Stock Chart

From Nov 2023 to Nov 2024