TIDMBSE

AIM and Media Release

30 October 2023

Base Resources Limited

Kwale East - Exploration update

Base Resources Limited (ASX & AIM: BSE) (Base Resources or the Company) advises

that, following conclusion of a limited phase 2 air core drilling program (Phase

2) at its Kwale East exploration project (Kwale East) in Kwale County, Kenya,

exploration activities at Kwale East have been discontinued.

Explorations activities undertaken

Kwale East is located within ProspectingLicence2018/0119 and is the eastern

expression of a large, mineralised Plio-Pleistocene dune system also covering

the Kwale Central, South and North Dunes and the Bumamani deposit - refer to

Figure 1. Kwale East was considered a near-term mine life extension opportunity

due to its close proximity to Kwale Operations' infrastructure.

An initial phase 1 scout auger drilling program (Phase 1) completed over 2022

and 2023 identified three targets - Magaoni, Masindini and Zigira - for follow

-up aircore drilling as part of Phase 2. Refer to Figure 2 for the location of

these target areas and the Phase 1 drill holes, and the Company's announcement

of 3 July 2023, titled "Kwale East exploration drilling update" (the July

Announcement), for further details in relation to Phase 1.

As was noted in the July Announcement, land access was a particular challenge in

the more prospective areas of Magaoni and Zigira during Phase 1, with access to

approximately 35% of those target areas unable to be obtained. With community

engagement trending positively and optimism over the Company's ability to secure

the necessary landholder consents, the Phase 2 program was commenced. The

priorities for Phase 2 were to:

· drill the remaining 35% of Magaoni and Zigira;

· complete infill drilling to achieve 100m north by 50m east spacing for all

three targets for resource estimate purposes; and

· twin Phase 1 drill holes with average HM grades of greater than 1% to enable

better sample quality and allow drilling through to basement, as well as confirm

mineralisation.

Despite securing some additional landholder consents, the Company was ultimately

unable to secure full access to the more prospective areas in Magaoni and

Zigira, largely limiting the program undertaken for Phase 2 to twinning some of

the Phase 1 holes. In total for Phase2, 65 holes for 1,054.5m were completed in

the Magaoni and Zigira target area, resulting in 703 samples - refer to Figure 2

for the location of these holes.

While the Phase 2 assay results confirmed the existence of the mineralisation

identified from the Phase 1 auger program, the Company has decided to

discontinue exploration activities at Kwale East. This decision followed an

evaluation of the likely mineralisation for the three targets using the results

from both Phase1 and Phase2 drill programs and applying optimistic assumptions

on the continuity of mineralisation in the Magaoni and Zigira target areas that

were not able to be drilled. Even on these optimistic assumptions, the

evaluation concluded that there is unlikely to be sufficient volume or heavy

mineral grade to support an economically viable mining development. For further

details about the evaluation undertaken, refer to the Company's announcement

titled "Kwale Operations to complete mining at end of 2024", also released

today.

For further details about the results from Phase 2 drilling, refer to the

Appendices below, comprising a table of assay results for all drill holes having

an average grade equal to or greater than 1% HM (refer to Appendix 1) and the

information provided for the purposes of Sections 1 and 2 of Table 1 of the JORC

Code (refer to Appendix 2). For completeness, Appendix 1 also discloses further

assay results from Phase 1 received subsequent to the cut-off for the July

Announcement and having an average grade equal to or greater than 1% HM, and

Appendix 2 also contains information provided for the purposes of Sections 1 and

2 of Table 1 of the JORC Code in respect for those assay results.

A glossary of key terms used in this announcement is contained below.

Competent Person's Statement

The information in this announcement that relates to Kwale East exploration

results is based on, and fairly represents, information and supporting

documentation prepared by Mr. Edwin Owino. Mr. Owino is a member of the

Australian Institute of Geoscientists. Mr.Owino is employed by Base Resources'

wholly-owned subsidiary, Base Titanium. Mr. Owino holds equity securities in

Base Resources and is entitled to participate in Base Resources' long-term

incentive plan and receive equity securities under that plan. Details about

that plan are included in Base Resources' 2023 Annual Report. Mr. Owino has

sufficient experience that is relevant to the style of mineralisation and type

of deposit under consideration and to the activity which he is undertaking to

qualify as a Competent Person as defined in the JORC Code and as a Qualified

Person for the purposes of the AIM Rules for Companies. Mr. Owino has reviewed

this announcement and consents to the inclusion in this announcement of the

Kwale East exploration results and the supporting information in the form and

context in which the relevant information appears.

Figure 1: Kwale East Project location

[A picture containing text, map, screenshot, diagram

Description automatically generated]

Figure 2: Kwale East Project drilling location

[A map of the united states

Description automatically generated]

Appendix 1

Kwale East drill hole table

All drill holes have dip of -90 degrees and azimuth of 0 degrees (i.e

vertical). Local coordinates given to allow cross reference to cross sections,

which are named after Local_Y. The table is sorted by a rounded Local_Y and

then by Local_X. The reported intervals are combined ore zones averaged from

the surface with a minimum 3m thickness that equals or exceed 1% HM. The reason

for averaging from the surface is that the hydraulic mining method, which would

likely be employed if any of this material were to be mined, results in the

blending of the various ore zones.

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|Hole_ID|Type |Arc60_X|Arc60_Y |Local_X|Local_Y|DTM_Z|From|To

|Interval|Avg|Avg |Avg |

| | | | | | | | | | | |

| |

| | | | | | | | | | |HM

|Slime|OS |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|MH348 |Auger|550,036|9,516,037|2,951 |10,650 |70 |0 |3 |3

|1.4|37.9 |0.9 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|MH347 |Auger|550,096|9,516,252|2,850 |10,850 |78 |0 |9 |9

|1.2|28.5 |0.7 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|MH349 |Auger|550,017|9,516,461|2,650 |10,950 |80 |0 |7.5 |7.5

|1.1|33.6 |0.8 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|MH350 |Auger|549,942|9,516,529|2,550 |10,950 |81 |0 |7.5 |7.5

|1.0|30.0 |1.0 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD052 |RCAC |551,503|9,515,640|4,300 |11,349 |52 |0 |7.5 |7.5

|1.0|18.7 |1.1 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD053 |RCAC |551,464|9,515,673|4,249 |11,347 |56 |0 |6 |6

|1.6|23.9 |1.9 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD054 |RCAC |551,430|9,515,708|4,201 |11,350 |56 |0 |4.5 |4.5

|1.7|38.4 |1.9 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD059 |RCAC |551,409|9,515,731|4,170 |11,353 |52 |0 |4.5 |4.5

|1.6|30.7 |1.8 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD046 |RCAC |551,502|9,515,710|4,252 |11,400 |57 |0 |7.5 |7.5

|1.3|24.6 |1.9 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD055 |RCAC |551,463|9,515,745|4,200 |11,399 |57 |0 |6 |6

|2.1|31.4 |2.6 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD058 |RCAC |551,435|9,515,774|4,160 |11,402 |52 |0 |3 |3

|1.6|18.6 |1.7 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD044 |RCAC |551,571|9,515,714|4,301 |11,449 |53 |0 |9 |9

|1.0|19.1 |1.0 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD045 |RCAC |551,534|9,515,749|4,250 |11,450 |58 |0 |6 |6

|1.7|21.4 |1.2 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD056 |RCAC |551,498|9,515,782|4,201 |11,450 |59 |0 |7.5 |7.5

|2.4|28.0 |2.7 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD057 |RCAC |551,460|9,515,816|4,150 |11,450 |53 |0 |4.5 |4.5

|1.8|29.4 |2.1 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD039 |RCAC |551,639|9,515,788|4,301 |11,550 |54 |0 |10.5|10.5

|1.5|22.3 |1.3 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD038 |RCAC |551,607|9,515,822|4,254 |11,553 |58 |0 |7.5 |7.5

|1.8|19.0 |0.9 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD037 |RCAC |551,564|9,515,856|4,200 |11,549 |62 |0 |9 |9

|1.7|24.9 |0.8 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD060 |RCAC |551,536|9,515,893|4,154 |11,558 |58 |0 |4.5 |4.5

|1.6|28.5 |1.8 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD061 |RCAC |551,512|9,515,911|4,124 |11,555 |53 |0 |4.5 |4.5

|1.4|29.6 |1.2 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD035 |RCAC |551,670|9,515,895|4,251 |11,650 |60 |0 |10.5|10.5

|1.5|25.6 |1.8 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD036 |RCAC |551,633|9,515,930|4,200 |11,651 |63 |0 |12 |12

|2.4|22.4 |1.1 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD064 |RCAC |551,595|9,515,964|4,149 |11,650 |59 |0 |4.5 |4.5

|2.2|26.0 |1.1 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD063 |RCAC |551,577|9,515,980|4,125 |11,650 |54 |0 |3 |3

|2.2|25.2 |1.2 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD062 |RCAC |551,559|9,515,997|4,101 |11,650 |51 |0 |6 |6

|1.4|25.9 |1.3 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|MH351 |Auger|551,079|9,516,436|3,450 |11,650 |72 |0 |12 |12

|1.0|18.9 |0.9 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|MH346 |Auger|551,005|9,516,504|3,350 |11,650 |69 |0 |3 |3

|1.0|29.8 |0.8 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD002 |RCAC |551,769|9,515,944|4,295 |11,750 |56 |0 |4.5 |4.5

|1.2|19.8 |1.2 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD003 |RCAC |551,734|9,515,974|4,251 |11,750 |61 |0 |10.5|10.5

|1.7|25.6 |1.4 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD007 |RCAC |551,697|9,516,007|4,199 |11,748 |64 |0 |12 |12

|2.2|22.2 |1.7 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD065 |RCAC |551,626|9,516,071|4,100 |11,750 |51 |0 |6 |6

|1.8|24.5 |3.2 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD008 |RCAC |551,765|9,516,081|4,201 |11,850 |62 |0 |12 |12

|1.1|24.4 |1.0 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD026 |RCAC |551,945|9,516,049|4,350 |11,949 |51 |0 |7.5 |7.5

|1.5|17.7 |1.5 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD027 |RCAC |551,909|9,516,083|4,301 |11,950 |54 |0 |7.5 |7.5

|1.5|23.4 |1.8 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD028 |RCAC |551,873|9,516,117|4,251 |11,951 |55 |0 |6 |6

|1.2|26.7 |1.2 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD029 |RCAC |551,835|9,516,151|4,200 |11,950 |51 |0 |3 |3

|1.3|23.7 |2.1 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD031 |RCAC |551,976|9,516,157|4,300 |12,050 |46 |0 |4.5 |4.5

|1.0|15.7 |2.1 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD030 |RCAC |551,941|9,516,181|4,258 |12,044 |46 |0 |6 |6

|1.0|14.9 |3.7 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD019 |RCAC |551,775|9,516,597|3,864 |12,236 |74 |0 |16.5|16.5

|3.8|16.8 |0.5 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD017 |RCAC |551,941|9,516,595|3,984 |12,347 |72 |0 |16.5|16.5

|4.1|16.4 |0.7 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD018 |RCAC |551,927|9,516,612|3,960 |12,347 |72 |0 |18 |18

|4.5|16.5 |1.0 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD004 |RCAC |551,871|9,516,656|3,891 |12,345 |74 |0 |18 |18

|5.1|16.8 |0.8 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD015 |RCAC |552,047|9,516,634|4,040 |12,445 |69 |0 |16.5|16.5

|3.8|18.2 |1.1 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD014 |RCAC |552,023|9,516,662|4,000 |12,449 |71 |0 |18 |18

|4.0|15.8 |0.8 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD006 |RCAC |551,988|9,516,695|3,951 |12,449 |73 |0 |19.5|19.5

|6.5|15.6 |1.6 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD005 |RCAC |551,943|9,516,721|3,901 |12,450 |74 |0 |18 |18

|3.9|19.0 |1.3 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD016 |RCAC |551,902|9,516,744|3,855 |12,433 |74 |0 |16.5|16.5

|1.8|17.8 |0.6 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|KE923 |Auger|552,010|9,516,940|3,796 |12,650 |72 |0 |7.5 |7.5

|1.0|23.7 |0.8 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|KE922 |Auger|551,976|9,516,971|3,750 |12,650 |71 |0 |4.5 |4.5

|1.0|24.7 |0.7 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|KE920 |Auger|552,007|9,517,078|3,701 |12,750 |66 |0 |4.5 |4.5

|1.0|31.6 |1.0 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|KE901 |Auger|553,202|9,517,200|4,499 |13,647 |58 |0 |9 |9

|1.2|28.3 |2.2 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|KE899 |Auger|553,494|9,517,072|4,801 |13,750 |47 |0 |7.5 |7.5

|3.5|11.6 |4.8 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|KE915 |Auger|553,633|9,517,081|4,898 |13,851 |45 |0 |9 |9

|5.1|12.8 |3.5 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|KE900 |Auger|553,551|9,517,145|4,794 |13,843 |49 |0 |4.5 |4.5

|1.0|10.2 |2.4 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|KE918 |Auger|553,766|9,517,083|4,994 |13,941 |45 |0 |6 |6

|1.4|17.1 |8.0 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|KE912 |Auger|553,503|9,517,603|4,449 |14,148 |59 |0 |6 |6

|1.1|21.8 |1.1 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|KE911 |Auger|553,646|9,517,592|4,562 |14,236 |57 |0 |7.5 |7.5

|1.2|28.9 |1.4 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|NE079 |Auger|552,614|9,518,556|3,150 |14,250 |69 |0 |6 |6

|1.3|37.2 |0.5 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|NE080 |Auger|552,541|9,518,624|3,050 |14,250 |72 |0 |9 |9

|1.3|36.1 |0.6 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|NE104 |Auger|551,657|9,519,434|1,851 |14,250 |90 |0 |3 |3

|1.3|39.5 |1.0 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|NE103 |Auger|551,583|9,519,501|1,751 |14,250 |91 |0 |3 |3

|1.7|37.0 |1.8 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|NE112 |Auger|551,509|9,519,569|1,650 |14,250 |92 |0 |3 |3

|1.9|43.7 |0.9 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|NE119 |Auger|551,436|9,519,637|1,551 |14,251 |90 |0 |9 |9

|1.4|29.9 |0.4 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD024 |RCAC |554,120|9,517,312|5,100 |14,350 |47 |0 |9 |9

|2.1|11.8 |5.1 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|NE115 |Auger|553,051|9,518,292|3,650 |14,350 |79 |0 |13.5|13.5

|1.8|26.2 |1.1 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|NE114 |Auger|552,977|9,518,359|3,550 |14,349 |79 |0 |9 |9

|1.2|28.4 |0.9 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|NE109 |Auger|552,904|9,518,426|3,451 |14,350 |78 |0 |9 |9

|1.2|34.4 |1.3 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|NE120 |Auger|552,534|9,518,761|2,952 |14,347 |80 |0 |19.5|19.5

|1.7|21.9 |0.6 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|NE121 |Auger|552,460|9,518,829|2,852 |14,347 |82 |0 |18 |18

|1.6|23.7 |0.9 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|NE129 |Auger|552,386|9,518,896|2,752 |14,346 |81 |0 |7.5 |7.5

|1.0|28.6 |0.6 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|NE125 |Auger|552,312|9,518,964|2,651 |14,346 |76 |0 |3 |3

|1.1|41.3 |0.7 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|NE136 |Auger|552,165|9,519,099|2,452 |14,346 |67 |0 |4.5 |4.5

|1.1|34.1 |1.3 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|NE135 |Auger|552,091|9,519,167|2,351 |14,347 |72 |0 |4.5 |4.5

|1.3|41.1 |1.1 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD023 |RCAC |554,299|9,517,285|5,251 |14,451 |45 |0 |3 |3

|1.3|5.4 |2.8 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD022 |RCAC |554,261|9,517,318|5,200 |14,449 |45 |0 |6 |6

|2.5|7.2 |11.1|

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD021 |RCAC |554,224|9,517,355|5,148 |14,452 |47 |0 |9 |9

|1.9|11.3 |6.7 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|CD020 |RCAC |554,188|9,517,385|5,101 |14,450 |48 |0 |9 |9

|1.7|8.6 |3.5 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|NE095 |Auger|552,677|9,518,770|3,051 |14,450 |81 |0 |18 |18

|1.6|21.7 |0.5 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|NE122 |Auger|552,528|9,518,907|2,849 |14,450 |83 |0 |13.5|13.5

|1.3|30.2 |0.6 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|NE148 |Auger|552,238|9,519,170|2,458 |14,448 |69 |0 |6 |6

|1.1|26.8 |0.8 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|NE084 |Auger|551,643|9,519,716|1,650 |14,449 |103 |0 |7.5 |7.5

|1.2|37.2 |0.1 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|NE085 |Auger|551,571|9,519,784|1,550 |14,450 |107 |0 |6 |6

|1.8|44.9 |0.0 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|NE124 |Auger|552,448|9,519,111|2,652 |14,547 |81 |0 |3 |3

|1.0|27.9 |0.3 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|NE123 |Auger|552,374|9,519,179|2,552 |14,547 |78 |0 |3 |3

|1.1|34.4 |0.3 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|NE110 |Auger|551,779|9,519,864|1,650 |14,650 |102 |0 |9 |9

|1.1|27.4 |0.3 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|NE099 |Auger|553,407|9,518,519|3,759 |14,758 |73 |0 |7.5 |7.5

|1.1|32.8 |2.1 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|NE118 |Auger|552,953|9,518,924|3,151 |14,750 |81 |0 |15 |15

|1.4|26.8 |0.5 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|NE139 |Auger|553,308|9,518,866|3,452 |14,947 |77 |0 |16.5|16.5

|1.2|25.3 |1.4 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|NE133 |Auger|553,234|9,518,933|3,352 |14,946 |76 |0 |13.5|13.5

|1.2|27.4 |1.8 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|NE144 |Auger|553,081|9,519,213|3,050 |15,049 |81 |0 |9 |9

|1.2|30.7 |0.5 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|NE089 |Auger|553,143|9,519,428|2,950 |15,250 |83 |0 |9 |9

|1.1|36.0 |0.8 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|NE107 |Auger|553,942|9,518,968|3,850 |15,450 |70 |0 |3 |3

|1.0|36.2 |0.6 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|NE105 |Auger|553,868|9,519,035|3,751 |15,450 |75 |0 |6 |6

|1.1|37.5 |2.6 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|NE090 |Auger|553,720|9,519,170|3,550 |15,450 |80 |0 |12 |12

|1.1|32.2 |1.0 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

|NE096 |Auger|554,200|9,519,545|3,651 |16,050 |57 |0 |3 |3

|1.1|26.7 |2.4 |

+-------+-----+-------+---------+-------+-------+-----+----+----+--------+---+--

---+----+

Appendix 2

JORC Code - Section 1 Sampling Techniques and Data

+---------------------------+----------------+---------------------------------

-+

|Criteria |Explanation |Comment

|

+---------------------------+----------------+---------------------------------

-+

|Sampling techniques |Nature and |For holes prefixed GN, KE, MH and

|

| |quality of |NE mechanised auger drilling was

|

| |sampling (e.g., |used to obtain 1.5m samples from

|

| |cut channels, |which approximately 4.0kg was

|

| |random chips, |collected via composite grab

|

| |or specific |sampling of a homogenised sample

|

| |specialised |to produce a sub-sample for HM

|

| |industry |analysis utilising heavy liquid

|

| |standard |separation, magnetic separation

|

| |measurement |and XRF assay.

|

| |tools |

|

| |appropriate to |All holes were sampled over

|

| |the minerals |consistent 1.5m intervals.

|

| |under |Several programs of twin drilling

|

| |investigation, |of air core holes have been

|

| |such as down |undertaken and, while some

|

| |hole gamma |variability was observed, it was

|

| |sondes, or |concluded that auger drilling is

|

| |handheld XRF |appropriate for reconnaissance

|

| |instruments, |drilling to identify

|

| |etc). These |mineralisation potential.

|

| |examples should |

|

| |not be taken as |For holes prefixed CD, reverse

|

| |limiting the |circulation aircore drilling was

|

| |broad meaning |used to collect the entire 1.5m

|

| |of sampling. |downhole sample averaging 10kg

|

| | |from which approximately 3kg was

|

| |Include |collected via two-stage riffle

|

| |reference to |splitting.

|

| |measures taken |

|

| |to ensure |Samples were analysed by mineral

|

| |sample |sands industry standard

techniques|

| |representivity |of screening, desliming and heavy

|

| |and the |liquid separation using SPT

|

| |appropriate |(sodium polytungstate: SG =

|

| |calibration of |2.85g/cm3). XRF analysis of HM

|

| |any measurement |magnetic fractions was used to

|

| |tools or |define the VHM content.

|

| |systems used. |

|

| | |

|

| |Aspects of the |

|

| |determination |

|

| |of |

|

| |mineralisation |

|

| |that are |

|

| |Material to the |

|

| |Public Report. |

|

| |In cases where |

|

| |`industry |

|

| |standard' work |

|

| |has been done |

|

| |this would be |

|

| |relatively |

|

| |simple (e.g., |

|

| |`reverse |

|

| |circulation |

|

| |drilling was |

|

| |used to obtain |

|

| |1 m samples |

|

| |from which 3 kg |

|

| |was pulverised |

|

| |to produce a 30 |

|

| |g charge for |

|

| |fire assay'). |

|

| |In other cases, |

|

| |more |

|

| |explanation may |

|

| |be required, |

|

| |such as where |

|

| |there is coarse |

|

| |gold that has |

|

| |inherent |

|

| |sampling |

|

| |problems. |

|

| |Unusual |

|

| |commodities or |

|

| |mineralisation |

|

| |types (e.g., |

|

| |submarine |

|

| |nodules) may |

|

| |warrant |

|

| |disclosure of |

|

| |detailed |

|

| |information. |

|

+---------------------------+----------------+---------------------------------

-+

|Drilling techniques |Drill type |Holes prefixed GN, KE, MH and NE

|

| |(e.g., core, |were drilled using trailer

mounted|

| |reverse |mechanised auger equipment, with

|

| |circulation, |the fleet comprising three rigs

|

| |open-hole |utilising the dead stick auger

|

| |hammer, rotary |method (0.5m sample runs) and one

|

| |air blast, |rig utilising the continuous

|

| |auger, Bangka, |flight auger method.

|

| |sonic, etc) and |

|

| |details (e.g., |All holes were drilled vertically

|

| |core diameter, |with the trailer levelled using

|

| |triple or |site preparation and manual jack

|

| |standard tube, |legs.

|

| |depth of |

|

| |diamond tails, |Hole diameter was approximately

4"|

| |face-sampling |or 102 mm.

|

| |bit or other |

|

| |type, whether |Holes prefixed CD were drilled

|

| |core is |used a truck mounted RCAC EVH

2100|

| |oriented and if |drill rig using remet drill rods

|

| |so, by what |of 75mm diameter and a 3 blade

|

| |method, etc). |aircore vacuum sampling bit.

|

| | |

|

| | |All holes were drilled vertically

|

| | |with the rig levelled using site

|

| | |preparation and rear hydraulic

|

| | |jacks.

|

+---------------------------+----------------+---------------------------------

-+

|Drill sample recovery |Method of |Sample condition was logged at

the|

| |recording and |rig as either good, moderate or

|

| |assessing core |poor, with good meaning not

|

| |and chip sample |contaminated and appropriate

|

| |recoveries and |sample size (recovery), moderate

|

| |results |meaning not contaminated, but

|

| |assessed. |sample over or undersized, and

|

| | |poor meaning contaminated or

|

| |Measures taken |grossly over/undersized.

|

| |to maximise |

|

| |sample recovery |It is recognised that open hole

|

| |and ensure |auger drilling is subject to

|

| |representative |potential sample contamination by

|

| |nature of the |smearing as the sample is

|

| |samples. |retrieved (both methods) and

|

| | |material falling downhole during

|

| |Whether a |running of the drill string (dead

|

| |relationship |stick method). To counter

|

| |exists between |downhole contamination the

driller|

| |sample recovery |nominates material for rejection

|

| |and grade and |as potential contamination on

each|

| |whether sample |0.5m drill run.

|

| |bias may have |

|

| |occurred due to |Moist ground conditions meant

that|

| |preferential |best sample quality for aircore

|

| |loss/gain of |drilling was found to be achieved

|

| |fine/coarse |via slow penetration with water

|

| |material. |injection to aid in the sample

|

| | |recovery.

|

| | |

|

| | |No relationship is believed to

|

| | |exist between grade and sample

|

| | |recovery. No bias is also

|

| | |believed to occur due to loss of

|

| | |fine material.

|

+---------------------------+----------------+---------------------------------

-+

|Logging |Whether core |All samples were visually checked

|

| |and chip |on site and a summary log was

|

| |samples have |completed by the site geologist.

|

| |been |For the initial auger drilling,

|

| |geologically |detailed logging was completed

off|

| |and |-site to avoid speculation by

|

| |geotechnically |community observers, whereas for

|

| |logged to a |the aircore drilling, logging was

|

| |level of detail |completed on-site to also capture

|

| |to support |ground conditions. Samples are

|

| |appropriate |logged for lithotype, grain size,

|

| |Mineral |colour, hardness, and moisture

|

| |Resource |content. Logging was based on a

|

| |estimation, |representative grab sample that

|

| |mining studies |was panned for heavy mineral

|

| |and |estimation and host material

|

| |metallurgical |observations.

|

| |studies. |

|

| | |Logging codes were developed into

|

| |Whether logging |the logging software (LogChief)

to|

| |is qualitative |capture observations on

lithology,|

| |or quantitative |colour, grainsize, induration and

|

| |in nature. Core |estimated mineralisation. Any

|

| |(or costean, |relevant comments e.g., water

|

| |channel, etc) |table, hardness, gangue HM

|

| |photography. |components and stratigraphic

|

| | |markers (e.g fossilised wood)

were|

| |The total |included to aid in the subsequent

|

| |length and |geological modelling.

|

| |percentage of |

|

| |the relevant |

|

| |intersections |

|

| |logged. |

|

+---------------------------+----------------+---------------------------------

-+

|Sub-sampling techniques and|If core, |For the auger holes an

approximate|

|sample preparation |whether cut or |25% split of the drilled sample

|

| |sawn and |interval is collected on site via

|

| |whether |manual cone and quarter composite

|

| |quarter, half |grab sampling.

|

| |or all core |

|

| |taken. |For aircore holes the entire

|

| | |sample interval was collected

|

| |If non-core, |mostly wet and bagged on site in

|

| |whether |polyweave bags with internal

|

| |riffled, tube |plastic lining to avoid loss of

|

| |sampled, rotary |slimes. Following air drying of

|

| |split, etc and |excess moisture an approximate

25%|

| |whether sampled |split of the drilled sample

|

| |wet or dry. |interval was collected via riffle

|

| | |splitting.

|

| |For all sample |

|

| |types, the |The split sample was processed in

|

| |nature, quality |a dedicated sample preparation

|

| |and |facility where it was air-dried

|

| |appropriateness |when weather permitted, otherwise

|

| |of the sample |it was oven dried during the

rainy|

| |preparation |season. After drying, the sample

|

| |technique. |was rotary split to produce a

200|

| | |-400g sample for analytical

work. |

| |Quality control |The remaining drill sample

|

| |procedures |material was combined and split

|

| |adopted for all |down to 2-3kgs for storage.

|

| |sub-sampling |Improvements to the sample

|

| |stages to |preparation stage were made in

|

| |maximise |recent years to ensure industry

|

| |representivity |best practice and to deliver a

|

| |of samples. |high degree of confidence in the

|

| | |results. These included the

|

| |Measures taken |following:

|

| |to ensure that |

|

| |the sampling is | · A formalised process flow was

|

| |representative |generated, posted in all sample

|

| |of the in-situ |preparation areas and used to

|

| |material |train and monitor sample

|

| |collected, |preparation staff.

|

| |including for | · Regular monitoring was

|

| |instance |completed by Base Titanium senior

|

| |results for |staff.

|

| |field | · Field samples were left in

|

| |duplicate/second|their bags for initial air-drying

|

| |-half sampling. |to avoid sample loss.

|

| | | · TSPP dispersant was

introduced|

| |Whether sample |to decrease attrition time and

|

| |sizes are |improve slimes recovery. A range

|

| |appropriate to |of attrition times (with 5% TSPP)

|

| |the grain size |were trialled and plotted against

|

| |of the material |slimes recovery figures to

|

| |being sampled. |determine optimum attrition time

|

| | |(15 minutes).

|

| | | · Staff were trained to use

|

| | |paint brushes and water spray

|

| | |rather than manipulate sample

|

| | |through slimes screen by hand to

|

| | |remove the potential for screen

|

| | |damage.

|

| | | · A calibration schedule was

|

| | |introduced for scales used in the

|

| | |sample preparation stage.

|

| | | · The introduction of LIMS

|

| | |software allowed the capture of

|

| | |sample preparation data digitally

|

| | |at inception and synchronisation

|

| | |in real-time to the master Kwale

|

| | |Laboratory database.

|

| | | · Slimes screen number recorded

|

| | |to isolate batches should re

-assay|

| | |be required due to poor adherence

|

| | |to procedure or to identify

screen|

| | |damage.

|

| | |

|

| | |The sample preparation flow sheet

|

| | |follows conventional mineral

sands|

| | |processes but departed from

|

| | |standard mineral sand practices

in|

| | |one respect; the samples were

|

| | |generally not oven dried prior to

|

| | |de-sliming to prevent clay

|

| | |minerals being baked onto the HM

|

| | |grains (because the HM fractions

|

| | |were to be used in further

|

| | |mineralogical test work).

|

| | |Instead, a separate sample was

|

| | |split and dried to determine

|

| | |moisture content, which was

|

| | |accounted for mathematically.

|

| | |

|

| | |Pre-soaking of the sample TSPP

|

| | |dispersant solution ensured a

more|

| | |efficient de-sliming process and

|

| | |avoided potentially under

|

| | |-reporting slimes content.

|

| | |

|

| | |QA/QC procedures involved the

|

| | |following:

|

| | |

|

| | | · Prepared laboratory duplicate

|

| | |split samples were processed at

|

| | |every 20th sample.

|

| | | · Prepared laboratory repeat

|

| | |samples were processed at every

|

| | |7th sample.

|

| | |

|

| | |The manual hard-copy sample

|

| | |preparation records are

maintained|

| | |in files in the event of cross

|

| | |-references due to identified

|

| | |scribing errors into LIMS

|

| | |software.

|

| | |

|

| | |The sample size is considered

|

| | |appropriate for the grain size of

|

| | |the material because the grade of

|

| | |HM is measured in per cent.

|

+---------------------------+----------------+---------------------------------

-+

|Quality of assay data and |The nature, |Samples were analysed by

|

|laboratory tests |quality and |conventional mineral sands

|

| |appropriateness |techniques of screening,

desliming|

| |of the assaying |and heavy liquid separation using

|

| |and laboratory |SPT (sodium polytungstate: SG =

|

| |procedures used |2.85g/cm3). XRF analysis of HM

|

| |and whether the |magnetic fractions was used to

|

| |technique is |estimate the VHM content.

|

| |considered |

|

| |partial or |All drill samples were submitted

|

| |total. |to the Kwale Operations

|

| | |laboratory, with the following

|

| |For geophysical |approach adopted.

|

| |tools, |

|

| |spectrometers, | · All samples were dried and

|

| |handheld XRF |weighed.

|

| |instruments, | · Split to a 200-400 g sub

|

| |etc, the |-sample using a rotary splitter.

|

| |parameters used | · Wet screened using 45 µm and

1|

| |in determining |mm sieves, to generate oversize

|

| |the analysis |and sand fractions, with slimes

|

| |including |lost during screening and

|

| |instrument make |calculated by difference.

|

| |and model, | · Sand fraction processed by

SPT|

| |reading times, |heavy liquid separation to

|

| |calibrations |generate a HM fraction.

|

| |factors applied | · HM fraction subject to

|

| |and their |magnetic separation on a roll

|

| |derivation, |magnet to generate a magnetic

|

| |etc. |(Mag) fraction and non-magnetic

|

| | |(NonMag) fraction.

|

| |Nature of | · XRF analysis of magnetic

|

| |quality control |fractions, with rutile (assumed

|

| |procedures |95% TiO2) calculated from TiO2

|

| |adopted (e.g., |assay of NonMag by dividing by

|

| |standards, |0.95, zircon calculated from ZrO2

|

| |blanks, |assay of NonMag, and ilmenite

|

| |duplicates, |(assumed 54% TiO2 average)

|

| |external |calculated from TiO2 assay of Mag

|

| |laboratory |by dividing by 0.54.

|

| |checks) and | · Various quality control

|

| |whether |samples were submitted routinely

|

| |acceptable |to ensure assay quality. A total

|

| |levels of |of 494 duplicate field samples,

|

| |accuracy (i.e., |492 laboratory duplicate

samples,|

| |lack of bias) |906 laboratory repeat samples and

|

| |and precision |26 internal field standards have

|

| |have been |been assayed at Kwale Operations'

|

| |established. |site laboratory.

|

+---------------------------+----------------+---------------------------------

-+

|Verification of sampling |The |Drill hole logging and site

sample|

|and assaying |verification of |data was collected electronically

|

| |significant |in Maxwell LogChief software,

|

| |intersections |installed on field Panasonic

|

| |by either |Toughpads and which synchronise

|

| |independent or |directly to the Maxwell DataShed

|

| |alternative |exploration database software

|

| |company |hosted on the Base Titanium

|

| |personnel. |network server. Assay data was

|

| | |captured electronically via LIMS

|

| |The use of |software and merged with logging

|

| |twinned holes. |and sample data in Datashed.

|

| | |

|

| |Documentation |No adjustment to assay data was

|

| |of primary |made.

|

| |data, data |

|

| |entry |

|

| |procedures, |

|

| |data |

|

| |verification, |

|

| |data storage |

|

| |(physical and |

|

| |electronic) |

|

| |protocols. |

|

| | |

|

| |Discuss any |

|

| |adjustment to |

|

| |assay data. |

|

+---------------------------+----------------+---------------------------------

-+

|Location of data points |Accuracy and |Proposed drill holes were sited

on|

| |quality of |the ground using hand-held Garmin

|

| |surveys used to |GPS units which have an accuracy

|

| |locate drill |of between 3 and 5m. The auger

|

| |holes (collar |drill collars were surveyed using

|

| |and down-hole |the same instrumentation while 60

|

| |surveys), |out of 65 aircore holes were

|

| |trenches, mine |surveyed using real time

kinematic|

| |workings and |(RTK) DGPS unit.

|

| |other locations |

|

| |used in Mineral |The survey Geodetic datum

utilised|

| |Resource |was UTM Arc 1960, used in East

|

| |estimation. |Africa Arc 1960 references the

|

| | |Clark 1880 (RGS) ellipsoid and

the|

| |Specification |Greenwich prime meridian. All

|

| |of the grid |survey data used has undergone a

|

| |system used. |transformation to the local mine

|

| | |grid from the standard UTM Zone

|

| |Quality and |37S (Arc 1960). The local Grid is

|

| |adequacy of |rotated 42.5o, which aligns the

|

| |topographic |average strike of the deposit

with|

| |control. |local North and is useful for

both|

| | |grade interpolation and mining

|

| | |reference during production.

|

| | |

|

| | |The drill collars were projected

|

| | |to a merged local LIDAR and SRTM

|

| | |digital terrain model

|

+---------------------------+----------------+---------------------------------

-+

|Data spacing and |Data spacing |The drill data spacing for the

|

|distribution |for reporting |drilling was nominally 100m X,

50m|

| |of Exploration |Y and 1.5m Z. Variations from

|

| |Results. |this spacing resulted from access

|

| | |challenges.

|

| |Whether the |

|

| |data spacing, |This spacing and distribution is

|

| |and |considered sufficient to

establish|

| |distribution is |the degree of geological and

|

| |sufficient to |mineralisation continuity

|

| |establish the |appropriate for reconnaissance

|

| |degree of |exploration.

|

| |geological and |

|

| |grade |No sample compositing has been

|

| |continuity |applied for HM, slimes, oversize

|

| |appropriate for |and XRF assays.

|

| |the Mineral |

|

| |Resource and |

|

| |Ore Reserve |

|

| |estimation |

|

| |procedure(s) |

|

| |and |

|

| |classifications |

|

| |applied. |

|

| | |

|

| |Whether sample |

|

| |compositing has |

|

| |been applied. |

|

+---------------------------+----------------+---------------------------------

-+

|Orientation of data in |Whether the |With the geological setting being

|

|relation to geological |orientation of |a layered dunal/fluvial/maritime

|

|structure |sampling |sequences, the orientation of the

|

| |achieves |deposit mineralisation in general

|

| |unbiased |is sub-horizontal. All drill

|

| |sampling of |holes were orientated vertically

|

| |possible |to penetrate the sub-horizontal

|

| |structures and |mineralisation orthogonally.

|

| |the extent to |

|

| |which this is |Hole centres were spaced

nominally|

| |known, |at 50-200m. This cross-profiles

|

| |considering the |the dune so that variation can be

|

| |deposit type. |determined. Down hole intervals

|

| | |were nominated as 1.5m. This

|

| |If the |provides adequate sampling

|

| |relationship |resolution to capture the

|

| |between the |distribution and variability of

|

| |drilling |geology units and mineralisation

|

| |orientation and |encountered vertically down hole.

|

| |the orientation |

|

| |of key |The orientation of the drilling

is|

| |mineralised |considered appropriate for

testing|

| |structures is |the horizontal and vertical

extent|

| |considered to |of mineralisation without bias.

|

| |have introduced |

|

| |a sampling |

|

| |bias, this |

|

| |should be |

|

| |assessed and |

|

| |reported if |

|

| |material. |

|

+---------------------------+----------------+---------------------------------

-+

|Sample security |The measures |Sample residues from the

|

| |taken to ensure |preparatory stage were

transferred|

| |sample |to pallets and stored in a locked

|

| |security. |shed beside the warehouse at

Kwale|

| | |Operations.

|

| | |

|

| | |Residues from the Kwale

Operations|

| | |site laboratory were placed in

|

| | |labelled bags and stored in

|

| | |numbered boxes. Boxes were

placed|

| | |into a locked container beside

the|

| | |laboratory.

|

| | |

|

| | |Sample tables are housed on a

|

| | |secure, network-hosted SQL

|

| | |database. Full access rights are

|

| | |only granted to the Exploration

|

| | |Manager and senior IT personnel.

|

| | |

|

| | |Data is backed up every 12 hours

|

| | |and stored in perpetuity on a

|

| | |secure, site backup server.

|

+---------------------------+----------------+---------------------------------

-+

|Audits or reviews |The results of |In-house reviews were undertaken

|

| |any audits or |by Mr. Scott Carruthers and Mr.

|

| |reviews of |Ian Reudavey, both employees of

|

| |sampling |the Base Resources group and

|

| |techniques and |Competent Persons under the JORC

|

| |data. |Code.

|

+---------------------------+----------------+---------------------------------

-+

Section 2 Reporting of Exploration Results

(Criteria listed in the preceding section also apply to this section.)

Criteria Explanation Comment

Mineral tenement and land tenure Type, reference The Kwale East exploration

status name/number, area is situated on a

location and Prospecting Licence 100%

ownership owned by Base Titanium-

including PL/2018/0119 located in

agreements or Kwale County, Kenya. Base

material issues Titanium is a wholly owned

with third subsidiary of ASX and AIM

parties such as -listed resources company,

joint ventures, Base Resources.

partnerships,

overriding The 40km2 Prospecting

royalties, Licence was re-granted on

native title 26 of May 2021 for a

interests, second, three-year term

historical ending 25 May 2024.

sites,

wilderness or The PL is in good standing

national park with the Kenya State

and Department of Mining at

environmental the time of reporting,

settings. with all statutory

reporting and payments up

The security of to date.

the tenure held

at the time of Local landowners have been

reporting along generally supportive of

with any known exploration activities,

impediments to though blanket access was

obtaining a not achieved.

licence to

operate in the The existing Special

area. Mining Lease No. 23 is

adjacent to the PL. The

SML boundary has been

varied on multiple

occasions, most recently

to include the Bumamani

Project deposits.

The Kenyan Mining Act 2016

includes a provision for

existing mineral rights to

transition to mining

licences upon their expiry

on a priority basis.

Landowner access

permission is required to

both complete the

exploration program and

then progress conversion

of the PL to a mining

licence. The Mining Act

2016 provides greater

flexibility on securing

land rights, specifically

allowing for a mineral

right to be issued on

private land. The Mining

Act 2016 additionally,

provides for fair and

adequate compensation to

be paid to lawful

landowners, occupiers and

users.

Exploration done by other Acknowledgment No historical exploration

parties and appraisal of by third parties was

exploration by undertaken in the Kwale

other parties. East area.

Geology Deposit type, The Kwale East deposits

geological are primarily hosted in

setting and reddish dunal sands (Ore

style of Zone 1) which is underlain

mineralisation. by a transitional and

occasionally lateritic

zone (Ore Zone 4). To the

east and around the 50

-60mRL, these deposits are

hosted in shallow paleo

-beach sands (Ore Zone 20)

originating from a

Pleistocene marine

transgression event. This

zone is low in slime and

typically has a high

valuable heavy mineralogy

content.

All three formations have

a regional strike

direction of about 40

degrees East of North and

range in age from mid

-Pliocene to Pleistocene.

Drill hole Information A summary of all A tabulation of drilling

information data with significant

material to the intersections ?1% HM is

understanding of included in Appendix 1.

the exploration All drill hole locations

results are shown in Figure 2, and

including a those holes not tabulated

tabulation of have not reported

the following significant

information for intersections. The

all Material exclusion of detailed

drill holes: collar information for all

drill holes is justified

· easting and on the basis that:

northing of the

drill hole · auger drilling

collar represents a

· elevation or reconnaissance exploration

RL (Reduced tool with over 1,000 holes

Level - drilled; and

elevation above · the air core drilling

sea level in completed was primarily

metres) of the for better quality samples

drill hole in areas identified as

collar prospective by the auger

· dip and drilling program and to

azimuth of the ensure the holes were

hole drilled down to basement.

· down hole

length and Drilling by year (max, min

interception and average depths) is as

depth follows.

· hole length.

· 2018/2019

If the exclusion

of this · 123 air core drill

information is holes (depth: max 33m, min

justified on the 6m, avg 15m).

basis that the · Total 1,851.5m drilled

information is

not Material and · 2023

this exclusion

does not detract · 1,134 auger drill

from the holes (depth: max 24m, min

understanding of 3m, avg 11.5m).

the report, the · Total 13,105.5m

Competent Person drilled by auger

should clearly · 65 aircore drill holes

explain why this (depth: max 24m, min 6m,

is the case. avg 16m).

· Total 1,054.5m drilled

by aircore

All drill holes are

drilled vertically (-90

degrees). All collars

have been projected to the

DTM surface.

Data aggregation methods In reporting Exploration results are

Exploration reported as length

Results, weighted averages from

weighting surface. No grade cutting

averaging has been applied and a

techniques, nominal cut-off grade of

maximum and/or 1% HM has been utilised.

minimum grade However, lower grade

truncations intervals may be included

(e.g., cutting to provide geological

of high grades) continuity and in

and cut-off recognition of bulk mining

grades are techniques used for

usually Material mineral sands.

and should be

stated. No metal equivalent values

were used.

Where aggregate

intercepts

incorporate

short lengths of

high-grade

results and

longer lengths

of low-grade

results, the

procedure used

for such

aggregation

should be stated

and some typical

examples of such

aggregations

should be shown

in detail.

The assumptions

used for any

reporting of

metal equivalent

values should be

clearly stated.

Relationship between These The deposit sequences are

mineralisation widths and relationships sub-horizontal, and the

intercept lengths are particularly vertically inclined holes

important in the are a fair representation

reporting of of true thickness.

Exploration

Results.

If the geometry

of the

mineralisation

with respect to

the drill hole

angle is known,

its nature

should be

reported.

If it is not

known and only

the down hole

lengths are

reported, there

should be a

clear statement

to this effect

(e.g., `down

hole length,

true width not

known').

Diagrams Appropriate maps See body of the

and sections announcement - Figure 2.

(with scales) Additional diagrams,

and tabulations including cross sections,

of intercepts have not been included as

should be no significant discovery

included for any is being reported. Given

significant the Company's decision to

discovery being discontinue exploration

reported. These activities at Kwale East,

should include, these are not considered

but not be material. Further,

limited to a detailed cross sections

plan view of were included in the July

drill hole Announcement.

collar locations

and appropriate

sectional views.

Balanced reporting Where The drilling location plan

comprehensive shows the average HM assay

reporting of all results for all drill

Exploration holes.

Results is not

practicable,

representative

reporting of

both low and

high grades

and/or widths

should be

practiced to

avoid misleading

reporting of

Exploration

Results.

Other substantive exploration Other Geological observations

data exploration suggest that the Kwale

data, if East dunal material

meaningful and contains significantly

material, should lower slimes than the

be reported deposits currently being

including (but mined. This would be

not limited to): beneficial to support the

geological co-disposal of tails,

observations; while still having

geophysical sufficient slimes to

survey results; support hydraulic mining.

geochemical

survey results; Due to the reconnaissance

bulk samples - nature of exploration to

size and method date and the decision to

of treatment; not proceed with further

metallurgical exploration, there is no

test results; other substantive

bulk density, exploration data to

groundwater, report.

geotechnical and

rock

characteristics;

potential

deleterious or

contaminating

substances.

Further work The nature and Exploration activities at

scale of planned Kwale East have been

further work discontinued. This

(e.g., tests for decision followed an

lateral evaluation of the likely

extensions or mineralisation for the

depth extensions three targets using the

or large-scale results from the Phase 1

step-out and Phase 2 drill programs

drilling). and applying optimistic

assumptions on the

Diagrams clearly continuity of

highlighting the mineralisation in the

areas of Magaoni and Zigira target

possible areas that were not able

extensions, to be drilled. Even on

including the these optimistic

main geological assumptions, the

interpretations evaluation indicated that

and future there is unlikely be

drilling areas, sufficient volume or heavy

provided this mineral grade to support

information is an economically viable

not commercially mining development. For

sensitive. further details about the

evaluation undertaken,

refer to the Company's

announcement titled "Kwale

Operations to transition

to post-mining at end of

2024 as planned", also

released today.

Glossary

+----------+-------------------------------------------------------------------+

|Base |Base Resources' wholly-owned Kenyan operating subsidiary and the |

|Titanium |owner and operator of Kwale Operations. |

+----------+-------------------------------------------------------------------+

|collar |Location of a drill hole. |

+----------+-------------------------------------------------------------------+

|Competent |Has the meaning given in the JORC Code. |

|Person | |

| |The JORC Code requires that a Competent Person be a Member or |

| |Fellow of The Australasian Institute of Mining and Metallurgy, or |

| |of the Australian Institute of Geoscientists, or of a `Recognised |

| |Professional Organisation'. |

| | |

| |A Competent Person must have a minimum of five years' experience |

| |working with the style of mineralisation or type of deposit under |

| |consideration and relevant to the activity which that person is |

| |undertaking. |

+----------+-------------------------------------------------------------------+

|DTM |Digital Terrain Model. |

+----------+-------------------------------------------------------------------+

|GPS |Global positioning system. |

+----------+-------------------------------------------------------------------+

|HM |Heavy mineral. |

+----------+-------------------------------------------------------------------+

|JORC Code |The Australasian Code for Reporting of Exploration Results, Mineral|

| |Resources and Ore Reserves, as published by the Joint Ore Reserves |

| |Committee of The Australasian Institute of Mining and Metallurgy, |

| |Australian Institute of Geoscientists and Minerals Council of |

| |Australia. |

+----------+-------------------------------------------------------------------+

|Kwale |Base Titanium's mineral sands mining operations in Kwale County, |

|Operations|Kenya. |

+----------+-------------------------------------------------------------------+

|LIDAR |Light Detection and Ranging, a remote sensing method that uses |

| |pulsed laser to measure ranges. |

+----------+-------------------------------------------------------------------+

|LIMS |Laboratory information management system. |

+----------+-------------------------------------------------------------------+

|PL |Prospecting licence. |

+----------+-------------------------------------------------------------------+

|QA/QC |Quality assurance and quality control. |

+----------+-------------------------------------------------------------------+

|RCAC |Reverse circulation aircore drilling method |

+----------+-------------------------------------------------------------------+

|RL |Reduced level, equating elevations with reference to a common |

| |assumed vertical datum |

+----------+-------------------------------------------------------------------+

|SG |Specific gravity, or relative density. |

+----------+-------------------------------------------------------------------+

|SML |Special mining lease. |

+----------+-------------------------------------------------------------------+

|SPT |Sodium polytungstate heavy liquid used for mineral separation based|

| |on relative density. |

+----------+-------------------------------------------------------------------+

|SQL |Structured Query Language, a standardized programming language used|

| |to manage relational databases. |

+----------+-------------------------------------------------------------------+

|SRTM |Shuttle Radar Topography Mission, a modified radar system used by a|

| |Space Shuttle Endeavour mission to capture a high-resolution |

| |topographic database of the earth. |

+----------+-------------------------------------------------------------------+

|TSPP |Sodium (Tetra) Pyrophosphate. |

+----------+-------------------------------------------------------------------+

|UTM |Universal Transverse Mercator, a plane coordinate grid system. |

+----------+-------------------------------------------------------------------+

|VHM |Valuable heavy mineral. |

+----------+-------------------------------------------------------------------+

|XRF |A spectroscopic method used to determine the chemical composition |

| |of a material through analysis of secondary X-ray emissions, |

| |generated by excitation of a sample with primary X-rays that are |

| |characteristic of a particular element. |

+----------+-------------------------------------------------------------------+

ENDS.

For further information contact:

+--------------------------------+-----------------------------+

|Australian Media Relations |UK Media Relations |

+--------------------------------+-----------------------------+

|Citadel Magnus |Tavistock Communications |

+--------------------------------+-----------------------------+

|Cameron Gilenko and Michael Weir|Jos Simson and Gareth Tredway|

+--------------------------------+-----------------------------+

|Tel: +61 8 6160 4900 |Tel: +44 207 920 3150 |

+--------------------------------+-----------------------------+

About Base Resources

Base Resources is an Australian based, African focused, mineral sands producer

and developer with a track record of project delivery and operational

performance. The Company operates the established Kwale Operations in Kenya and

is developing the Toliara Project in Madagascar. Base Resources is an ASX and

AIM listed company. Further details about Base Resources are available at

www.baseresources.com.au.

PRINCIPAL & REGISTERED OFFICE

Level 3, 46 Colin Street

West Perth, Western Australia, 6005

Email: info@baseresources.com.au

Phone: +61 8 9413 7400

Fax: +61 8 9322 8912

NOMINATED ADVISER & JOINT BROKER

Canaccord Genuity Limited

James Asensio / Raj Khatri / George Grainger

Phone: +44 20 7523 8000

JOINT BROKER

Berenberg

Matthew Armitt / Detlir Elezi

Phone: +44 20 3207 7800

This information was brought to you by Cision http://news.cision.com

END

(END) Dow Jones Newswires

October 30, 2023 03:00 ET (07:00 GMT)

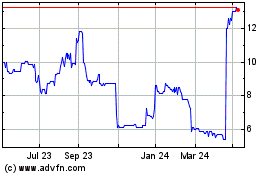

Base Resources (LSE:BSE)

Historical Stock Chart

From Mar 2024 to Apr 2024

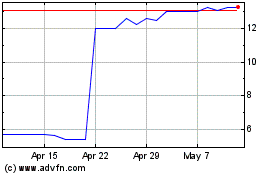

Base Resources (LSE:BSE)

Historical Stock Chart

From Apr 2023 to Apr 2024