Searchlight Minerals Corp. (OTCBB: SRCH) (the "Company"), an

exploration stage minerals company focused on the acquisition and

development of projects in the southwestern United States, is

pleased to provide the following update on activities at its

Clarkdale Slag Project in Clarkdale, Arizona.

Since the Company received all regulatory approval for the

operation of its initial production module in January 2009, the

Company has been testing the operation of the major equipment

components and processing circuits within its 100 to 250

ton-per-day production module. The Company has focused on

optimizing the results of operations of its precious metals circuit

for the extraction of gold and silver.

"Our initial goal has been to achieve consistent levels of gold

and silver extraction from pregnant solution and resins that would

support the economic feasibility of a commercial production

facility," stated Ian McNeil, Chief Executive Officer of the

Company. "I am pleased to report that we have made progress in this

regard. Our internal laboratory testing has reflected consistent

levels of extractable precious metals in pregnant leach solutions

from the Clarkdale slag material. We believe that we can improve

extraction rates further by optimizing the grind, the chemical

characteristics of the leach solutions and the amount of residence

time required for maximum grind and leach efficiency.

"Our crews have been running the precious metals circuit for

several weeks, and we have started to internally generate

consistent levels of extractable precious metals, including gold

and silver, on a repetitive basis. We have also commissioned tests

by independent and unaffiliated external laboratories to test and

analyze the pregnant leach solutions for precious metals content.

Although not final, the external labs have verbally and

preliminarily indicated to us that they have achieved similar

results to our internally generated findings.

The Company is also commencing an additional analytical check of

producing physical precious metals by fuming the loaded resins to

calculate extractable precious metals. "We intend to use both

analytical methods in order to evaluate our internal results

through the testing by independent laboratories, and to compare the

results to the previous chain-of-custody certification of the gold

grade of the slag pile," added McNeil.

"Based upon the preliminary results of the tests conducted by

these laboratories, the Company has now reached the stage where it

will soon engage an independent engineering firm to analyze the

internal operating results of the gold circuit, which we believe

comprises the majority of the potential value of the entire

Clarkdale Project," continued McNeil. "We will ask the independent

engineers to determine (1) that gold can be recovered from the slag

using our process and (2) the amount of troy ounces of gold

recoverable per ton of slag. This independent evaluation process

will be conducted in accordance with chain-of-custody standards. If

these prospective independent studies validate our preliminary

internal results, we believe that we will have a better

understanding of how to pursue the next milestones in the

achievement of our strategic business goals."

Current Operations

The Clarkdale facility is currently operating twenty-four hours

a day, seven days a week, in order to optimize the efficiency of

the first production module. The team at Clarkdale processes

material daily through the crushing and grinding circuits, with the

output from the vibratory grinder then delivered to the Company's

on-site laboratory for leaching and metals extraction analysis.

Full-scale leaching is also underway, and the chlorine dioxide

generator, a chemical feed to the leach circuit, has been installed

and is fully functional. Currently, the 'pregnant' leach solution

is being routed through a state-of-the-art series of Ion Exchange

(IX) recovery columns that are designed to extract gold and silver

from solution and load the metals on chelating resins with an

affinity for only precious metals.

"Our primary emphasis, to date, has been upon the optimization

of the crushing and grinding circuit, since a proper grind is

critical to the liberation of the sub-micron gold and silver

particles from tiny vienlets within the slag material," continued

McNeil. "Feed material must be properly ground and slurried into

the leaching tanks, where precious and base metals are dissolved

into solution. Upon exiting the series of six agitator tanks in the

leaching circuit, the remaining solids are removed in a filtration

system, leaving a 'pregnant solution' from which the metals can be

extracted in the IX recovery columns.

"During the 'shakedown' process that has been underway since

January, we have encountered a variety of challenges and delays not

uncommon to the start-up phase of any complex production process

designed to operate on a continuous basis. For example, the failure

of a heavy-duty mount beneath the 50-ton vibratory grinder

curtailed operations during February, and while the manufacturer

replaced the component under warranty as soon as possible, we lost

approximately two weeks of valuable grinding time as a result. All

components of the grinding circuit have been operating efficiently

since that time, and we have made progress in perfecting the grind

and evaluating resonance times in the grinder.

"We have experienced and overcome certain challenges within our

leach circuit, where the agitators, which are critical to the leach

process, had to be altered during the scale-up period. We were also

faced with some water balance issues following the addition of

certain chemicals to the circuit. Additionally, we have altered the

filtration circuit to accommodate the very fine material. We expect

to encounter other challenges as we progress towards continuous

plant operations, and I am confident in our team's ability to

address such issues on a timely basis as they arise.

"Even though the Project has taken longer than any of us desired

or expected, management and our technical team of advisors are very

pleased with the results that have been achieved. The Company will

be very active as we complete the independent verification of the

precious metals circuit and continue our progress towards running

the plant on a continuous basis once the base metal extraction

circuits are commissioned.

"It is important to recognize that commissioning of the base

metals circuits for the extraction of copper and zinc should be

forthcoming on a timely basis. During the start-up of the gold

circuit, the Company had to commission the crushing, grinding,

leaching, filtering and extraction processes. Start-up of the base

metals circuit begins with the pregnant solution and focuses on a

two-stage extraction process comprised of Ion Exchange resin

extraction and the electrowinning (EW) of plated metals. All of the

major equipment components have been installed in the EW building,

which is located adjacent to our primary production facility.

"Once the EW circuit has been commissioned and optimized, we

believe the Company will be able to start extracting copper and

zinc from pregnant solutions and operating the entire production

module on a continuous basis. The final two steps will involve a

feasibility study of the entire plant and assuming adequate sources

of financing are available, we anticipate expanding capacity by

adding multiple production modules," concluded McNeil.

About Searchlight Minerals Corp.

Searchlight Minerals Corp. is a minerals exploration company

focused on the acquisition and development of projects in the

southwestern United States. The Company is currently involved in

two projects: (1) the Clarkdale Slag Project, located in Clarkdale,

Arizona, is a reclamation project to recover precious and base

metals from the reprocessing of slag produced from the smelting of

copper ores mined at the United Verde Copper Mine in Jerome,

Arizona; and (2) the Searchlight Gold Project, which involves

exploration for precious metals on mining claims near Searchlight,

Nevada. The Clarkdale Project is the more advanced of two ongoing

projects that the Company is pursuing. The Searchlight Gold Project

is an early-stage gold exploration endeavor on 3,200 acres located

approximately 50 miles south of Las Vegas, Nevada.

Searchlight Minerals Corp. is headquartered in Henderson,

Nevada, and its common stock is listed on the OTC Bulletin Board

under the symbol "SRCH." Additional information is available on the

Company's website at www.searchlightminerals.com and in the

Company's filings with the U.S. Securities and Exchange

Commission.

Forward-Looking Statements

This Press Release may contain, in addition to historical

information, forward-looking statements. Statements in this news

release that are forward-looking statements are subject to various

risks and uncertainties concerning the specific factors disclosed

under the heading "Risk Factors" and elsewhere in the Company's

periodic filings with the U.S. Securities and Exchange Commission.

When used in this news release, the words such as "could," "plan,"

"estimate," "expect," "intend," "may," "potential," "should," and

similar expressions, are forward-looking statements. The risk

factors that could cause actual results to differ from these

forward-looking statements include, but are not restricted to the

Company's limited operating history, uncertainties about the

availability of additional financing, geological or mechanical

difficulties affecting the Company's planned geological or other

work programs, uncertainty of estimates of mineralized material,

operational risk, environmental risk, financial risk, currency risk

and other statements that are not historical facts as disclosed

under the heading "Risk Factors" and elsewhere in the Company's

periodic filings with securities regulators in the United States.

Consequently, risk factors including, but not limited to the

aforementioned, may result in significant delays to the projected

or anticipated production target dates.

Contact Information: Carl Ager Vice President (702) 939-5247

Email Contact or RJ Falkner & Company, Inc. Investor Relations

Counsel (800) 377-9893 Email Contact

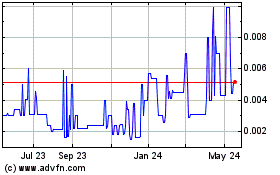

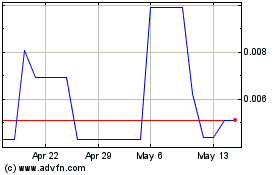

Searchlight Minerals (PK) (USOTC:SRCH)

Historical Stock Chart

From Jun 2024 to Jul 2024

Searchlight Minerals (PK) (USOTC:SRCH)

Historical Stock Chart

From Jul 2023 to Jul 2024