TIDMGWMO

RNS Number : 9914J

Great Western Mining Corp. plc

22 August 2023

GREAT WESTERN MINING CORPORATION PLC

("Great Western", "GWM" or the "Company")

Mill Construction Update

Great Western (AIM - GWMO, Euronext Growth - 8GW) provides the

following update on construction of its mill for producing precious

metals in Mineral County Nevada.

-- Process equipment assembled adjacent to site and ready to install

-- Foundations laid and concreted with retaining walls erected

-- Water bore holes and water monitoring wells concreted and complete

-- Access roads and laydown area complete

-- Final concrete pour to meet environmental standards waiting on contractor

-- Assembly and testing of plant will follow final concrete pour

-- NDEP site visit for provisional inspection this week

-- NDEP approval likely to be delayed by at least two months

-- Project costs within budget

PROJECT DESCRIPTION

Great Western and its partner Muletown Enterprizes LLC

('Muletown') are constructing a mill at Sodaville, close to Mina in

Mineral County, Nevada, to produce gold and silver concentrates

from spoil heaps left over from historic gold and silver mining

operations on claims held by the Company, together with tailings,

unprocessed stockpiles and in due course newly-mined shallow ore.

When this plant is operational, it will transform Great Western

from a pure mineral exploration company into combining exploration,

appraisal and production. The interests of Great Western and

Muletown are held through equal shares in a newly created vehicle,

Western Milling LCC (Western). Great Western has fulfilled the

terms of an earn-in to this venture and is a 50% interest holder in

Western.

The mill is being constructed on a naturally formed rock

feature, adjacent to and within easy access of a major highway,

which has been used for milling operations in the past. The mill

site is on private land owned by Muletown which it is leasing it to

Western for a nominal rent. Mains power is available and there is

an abundant supply of water in the immediate area. The first phase

of production is a simple gravity separation plant for which a

production permit application was lodged with NDEP (Nevada

Department of Environmental Protection) early this year. A planning

permit for the mill has already been approved but production

start-up is dependent on receiving NDEP consent.

In a second phase, tailings will be processed through an

encapsulated chemical leaching plant for further recovery of

precious metals. As this second phase will be more environmentally

sensitive than gravity separation, the joint venture aimed to speed

up the application process by applying only for gravity separation

in the first instance, with a view to achieving an earlier start-up

date for first production. Once the gravity permit has been

received, an application for chemical leaching will be filed with

NDEP. In the meantime, the plant has been designed and is being

built to cater for chemical leaching so that the second phase, when

approved, can be brought on production with minimal delay and

minimal additional cost.

Under the joint venture arrangement, Muletown is not only

providing the mill site at a nominal rent but also virtually all

the equipment needed for the milling plant from its own extensive

inventory, together with day-to-day supervision of plant

construction and operations. The main items that have been provided

by Muletown are a jaw crusher, a conveyor belt, a rod mill,

hydrocyclones, spirals, generators, water tanks, a shaker table and

a near-site laboratory, together with numerous smaller items. Some

of the main items, such as the jaw crusher and the shaker table,

are materially oversized and lend themselves to an expanded project

in the future. Great Western is funding (1) site construction and

(2) upgrading/modifying and installing the mill equipment for use

on site. Great Western's budget for this phase is not thought

likely to overrun.

CURRENT STATUS

To meet environmental requirements, the final concrete pour

cannot be carried out piecemeal and requires a continuous pour with

several concrete mixer trucks operating in tandem, the closest

contractor being a 2-hour drive from its base to the Western site.

Due to high construction demand in the area and a scarcity of local

contractors, it has not so far been possible to organise this final

pour except at an unacceptable premium to normal market rates.

Accordingly, Western has renovated and commissioned a concrete

plant on site which it has now used to lay foundations and complete

groundwork. When a contractor is available for the final part of

the job, Western's own plant will supplement this operation and

reduce the number of external truck loads required. At present

there is no agreed date for the operation but it is a very high

priority and will be carried out as soon as it can be arranged.

When a production application was submitted to NDEP, the

indicated turn-round estimate for receiving a permit was six months

and finalisation was estimated to be this month. However, NDEP has

recently advised that a heavy workload and staff shortages will

delay this by at least two more months. The additional time will be

well used to complete the project in the most effective manner.

NDEP will be carrying out a provisional site inspection this

week.

Great Western Chairman Brian Hall commented: "Delays are always

disappointing but in this case have been beyond the Company's

control. All the ingredients are in place to move forward and the

Western Milling joint venture remains an exciting project and a top

priority for the Great Western. Costs are being carefully

controlled and we plan to be ready for first production by the time

regulatory approval has been secured. We cannot guarantee the

timing of this approval but our aim is to be on production this

year".

For further information:

Great Western Mining Corporation

PLC

Brian Hall, Chairman +44 207 933 8780

Max Williams, Finance Director +44 207 933 8780

Davy (NOMAD, Euronext Growth Listing

Sponsor & Joint Broker)

Brian Garrahy +353 1 679 6363

SP Angel Corporate Finance LLP (Joint

Broker)

Ewan Leggat/Harry Davies-Ball +44 203 470 0470

Walbrook PR (PR advisers)

Nick Rome +44 207 933 8783

Notes to Editors

The Company has a large tract of acreage in Mineral County,

Nevada. The area consists of rugged, mountainous terrain, which

means that large parts of it remain under-explored. Mineral

potential is hosted by the regional Walker Lane Structural Belt,

the largest structural and metallogenic belt in Nevada, yet one of

the least explored in recent times, with gold, silver and copper

currently produced in Mineral County. Great Western has seven

distinct concession areas which offer the potential for exploiting

(1) short term gold and silver deposits and (2) long-term,

world-class copper deposits.

Six of the Company's properties are in the west of Mineral

County and are 100% owned and operated. The Company has an option

to acquire a seventh property, the Olympic Gold Project, in the

east of the county. Great Western's small exploration team is

supported by locally based consultants and contractors.

The state of Nevada is generally considered to be one of the

world's most mining friendly jurisdictions. While tightly regulated

and environmentally conscious, Nevada welcomes the mining industry.

Great Western takes care to ensure that its claims are maintained

in good standing and all regulations observed.

There are numerous gold and silver prospects on the Company's

acreage, including extensive historic mine workings which offer the

opportunity for secondary recovery. The Company is party to a 50-50

joint venture known as Western Milling LLC which is constructing a

mill to process pre-mined material for secondary recovery of gold

and silver.

Furthermore, through extensive drilling over a five-year period,

GWM has established a Mineral Resource on its first target area

known as M2, of 4.3 million tonnes at 0.45% copper, for 19,000

tonnes of contained copper metal. This resource has been

independently reported in accordance with JORC guidelines.

GWM has established an Inferred Resource Estimate of 31,000

tonnes grading 1.6 g/t gold and 3.0 g/t silver in tailings for the

OMCO Mine at the Olympic Gold Project. It has also established

Exploration targets. In addition, the Company has reported an

Exploration Target as follows:

-- 3,400 - 6,400 tonnes grading between 0.5 and 1.2 g/t Au and

1.2 and 2.1 g/t Ag in the substrate beneath the tailings volume at

the Olympic Mine.

-- 9,000 - 12,000 tonnes grading between 0.9 and 2.4 g/t Au and

2.0 and 5.1 g/t Ag in a coarse stockpile at Olympic Mine.

-- 4,200 - 7,700 tonnes grading between 40 and 140 g/t Ag and

0.3 and 0.3 g/t Au in spoil heaps at Mineral Jackpot.

This information is provided by RNS, the news service of the

London Stock Exchange. RNS is approved by the Financial Conduct

Authority to act as a Primary Information Provider in the United

Kingdom. Terms and conditions relating to the use and distribution

of this information may apply. For further information, please

contact rns@lseg.com or visit www.rns.com.

RNS may use your IP address to confirm compliance with the terms

and conditions, to analyse how you engage with the information

contained in this communication, and to share such analysis on an

anonymised basis with others as part of our commercial services.

For further information about how RNS and the London Stock Exchange

use the personal data you provide us, please see our Privacy

Policy.

END

UPDFLFVTTFILFIV

(END) Dow Jones Newswires

August 22, 2023 02:00 ET (06:00 GMT)

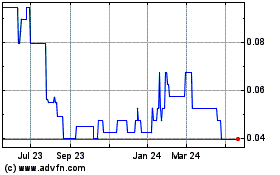

Great Western Mining (AQSE:GWMO.GB)

Historical Stock Chart

From Nov 2024 to Dec 2024

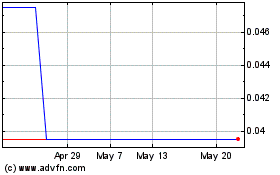

Great Western Mining (AQSE:GWMO.GB)

Historical Stock Chart

From Dec 2023 to Dec 2024