Blue Star Foods Corp., (“Blue Star,” the “Company,” “we,” “our” or

“us”) (NASDAQ:

BSFC), an

integrated Environmental, Social, and Governance (ESG) sustainable

seafood company with a focus on Recirculatory Aquaculture Systems

(RAS), that its looking to improve its soft-shell crab operations

by introducing cutting-edge technology that combines Artificial

Intelligence (AI) with Ultraviolet (UV) light technology to

revolutionize the industry’s standard molting crab identification

process.

The Atlantic blue crab, scientifically known as

Callinectes sapidus, goes through a molting process where it sheds

its old shell to form a new one. Identifying the precise moment

when crabs are in the molting stage (busters) and harvesting them

before they grow a new shell (soft crabs) is crucial for the

soft-shell crab industry, as soft-shell crabs are high value

seafood staple. The current traditional method of manual inspection

for identifying molting crabs is not only time-consuming but also

prone to errors, resulting in our view in high mortality rates and

operational inefficiencies.

Challenges & SolutionThe

high labor costs in the soft-shell crab shedding industry are

primarily attributed to visually & manually identifying molting

crabs (busters) from non-molting ones (peelers). By implementing an

AI system combined with UV light technology, the identification

process can be automated, significantly reducing labor hours and

costs, enhancing operational efficiency, and decreasing mortality

rates.

Our pilot facility operates 24/7 with three

shifts. First shift from 6 am to 2 pm, Second shift from 2 pm to 10

pm, Third shift (night shift) from 10 pm to 6 am. Observations

indicate that during the night shift, crabs molt at a higher rate.

Production peaks during this time, with a 30% increase in molting

crabs compared to the first and second shifts. Workers during the

night shift are more likely to be tired or distracted, making it

more difficult for them to accurately identify busters. This

increases the likelihood of errors and missed busters, which

negatively impact the yield and overall efficiency, resulting in

lower survival rate when comparing with the other 2 shifts. In this

traditional industry method, the correlation between increase

molting and mortality rate, shown an exponential growth curve.

However; in AI-UV light, we predict the correlation to be a

logistical growth curve. As molting rate increases, a mortality

rate stabilized over time as the AI system maps its processes.

The integration of AI with UV light technology

is expected to accurately and efficiently identify molting crabs,

leading to reduced labor hours, operational costs, and mortality

rates.

By harnessing the power of AI and UV light

technology, this innovative approach aims to automate the

identification process by training the system to recognize the

specific physiological changes in crabs during molting. UV light

will enhance the identification process by highlighting these

changes, enabling AI algorithms to differentiate between busters

and peelers accurately.

Operational Analysis and Expected

BenefitsThe implementation of AI and UV light technology

is forecasted to result in a reduction in labor costs (currently

15% of Blue Star Food’s soft-shell crab revenues), increased

operational efficiency, and improve the current yield rates by 50%,

resulting in potential increase profits of approximately 12.5% or

$9 per dozen [(*) based on our 2024 season average selling prices]

of live soft-shell crabs. The AI system can operate continuously

without fatigue, ensuring prompt and accurate identification of

molting crabs, thereby enhancing overall operational

efficiency.

Furthermore, the technology will aid in

identifying the optimal removal time for soft-shell crabs

post-molting, maximizing their quality and market value while

increasing our average biennial 75% survival rates and operational

profitability.

Pilot StudyAn ongoing pilot

study is conducted to gather and analyze key performance indicators

in the traditional manual method versus the AI-UV system across all

shifts, focusing on those KPI’s such as accuracy, labor hours,

mortality rates, and its costs.

Using AI Software to create a vision system that

monitors crab tanks under UV light, identifying molting crabs based

on fluorescence changes. Its graphical interface simplifies the

process of setting up and adjusting the vision system as needed,

crucial for accurately monitoring crab molting processes.

This groundbreaking initiative represents a

significant step forward in transforming the soft-shell crab

shedding process, paving the way for increased operational survival

rate efficiently, reduced labor costs, hence improved

profitability.

About Blue Star Foods Corp.

(NASDAQ: BSFC)Blue Star

Foods Corp. an integrated Environmental, Social, and Governance

(ESG) sustainable seafood company with a focus on Recirculatory

Aquaculture Systems (RAS) that processes, packages and sells

high-value seafood products. The Company believes it utilizes

best-in-class technology, in both resource sustainability

management and traceability, and ecological packaging. The Company

also owns and operates the oldest continuously operating

Recirculating Aquaculture System (RAS) full grow-out salmon farm in

North America. The company is based in Miami, Florida, and its

corporate website is: https://bluestarfoods.com

Forward-Looking Statements:The

foregoing material may contain “forward-looking statements” within

the meaning of Section 27A of the Securities Act of 1933 and

Section 21E of the Securities Exchange Act of 1934, each as

amended. Forward-looking statements include all statements that do

not relate solely to historical or current facts, including without

limitation statements regarding the Company’s product development

and business prospects, and can be identified by the use of words

such as “may,” “will,” “expect,” “project,” “estimate,”

“anticipate,” “plan,” “believe,” “potential,” “should,” “continue”

or the negative versions of those words or other comparable words.

Forward-looking statements are not guarantees of future actions or

performance. These forward-looking statements are based on

information currently available to the Company and its current

plans or expectations and are subject to a number of risks and

uncertainties that could significantly affect current plans. Risks

concerning the Company’s business are described in detail in the

Company’s Annual Report on Form 10-K for the year ended December

31, 2023, and other periodic and current reports filed with the

Securities and Exchange Commission. The Company is under no

obligation to, and expressly disclaims any such obligation to,

update or alter its forward-looking statements, whether as a result

of new information, future events or otherwise.

Investor Contacts:

investors@bluestarfoods.com

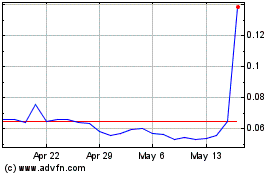

Blue Star Foods (NASDAQ:BSFC)

Historical Stock Chart

From Nov 2024 to Dec 2024

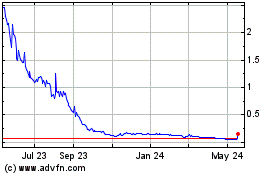

Blue Star Foods (NASDAQ:BSFC)

Historical Stock Chart

From Dec 2023 to Dec 2024