Fab 12A in Tainan, Taiwan is among 17 new

sites joining the Global Lighthouse Network

United Microelectronics Corporation (NYSE: UMC; TWSE:

2303)(“UMC”), a leading global semiconductor foundry, today

announced that its flagship Fab 12A in Tainan, Taiwan has been

selected for the World Economic Forum’s Global Lighthouse Network,

a group of 189 sites identified as exemplars in leveraging Fourth

Industrial Revolution (4IR) technologies to enhance operational

productivity, efficiency, and sustainable manufacturing. Fab 12A,

UMC’s largest production and research & development site, is

also the first semiconductor foundry globally to earn Lighthouse

status.

This press release features multimedia. View

the full release here:

https://www.businesswire.com/news/home/20250114984209/en/

Infographic: More than 48 Fourth

Industrial Revolution (4IR) solutions were deployed at UMC's Fab

12A to enhance operational productivity and efficiency. (Graphic:

Business Wire)

Lighthouses are designated by an independent panel of experts

based on their effective use of AI, industrial Internet of Things

(IIoT), big data analytics, and other digital technologies. The

Global Lighthouse Network, co-founded in 2018 by the World Economic

Forum and McKinsey & Company, now spans over 30 countries and

35 sectors.

UMC formed a dedicated smart manufacturing division in 2017, and

appointed Fab 12A as the pilot fab for digital transformation

initiatives, which are subsequently deployed to other UMC sites. To

date, more than 48 4IR solutions have been successfully integrated

into Fab 12A’s operations and value chain, nearly 95% of which are

developed or customized in-house. As a result, Fab 12A has reduced

design kit delivery time by 57%, increased product yields to 97%,

and raised workforce efficiency by 47%1, significantly enhancing

customer engagement, quality, and profitability.

TS Wu, Vice President of UMC and Head of Digital Office, said,

“We are honored to be recognized by the World Economic Forum as a

frontrunner in adopting smart manufacturing solutions at scale to

transform our business. 4IR is at the center of UMC’s sustainable

development, ensuring we can meet customers’ demands in an

increasingly competitive market. Smart manufacturing is also about

empowering our employees to focus on higher-value work and

optimizing resource use to reduce environmental impact. We are

excited to serve as a beacon for other manufacturers seeking to

harness digital tools as well as to learn from other Lighthouses in

the network.”

UMC focuses on the production of specialty semiconductors, which

have higher value but poses complex manufacturing challenges with

their unique functionalities and strict performance specifications.

The 4IR use cases deployed have helped overcome these challenges

and expanded customer engagements for UMC’s specialty portfolio,

enhancing the company’s overall profitability.

To accelerate time to market for customers, UMC leveraged

machine learning tools to shorten design kit creation lead time for

new fabrication processes by more than half. To ensure accuracy and

timely delivery of photomasks, UMC developed an AI-enabled platform

to streamline data handling between the company, customer, and

photomask vendor.

In order to reduce cycle time, UMC deployed a machine learning

predictive model and intelligent gas deployment system to target

key bottleneck tools. Additionally, an intelligent defect root

cause analysis system was created, incorporating smart image

recognition and automatic AI deciders, to quickly identify process

weaknesses and suspected tool issues. This system greatly increased

efficiency in defect root cause identification and tool

troubleshooting, effectively improving yields.

The Fab 12A site spans three separate but connected fabs, with

inter-fab production enabled by an intelligent Automated Material

Handling System (AMHS). With 3,000 pieces of equipment and 68

million possible routes a wafer can take throughout its

manufacturing process, UMC integrated AI algorithms with the

standard AMHS to automatically assign the optimal route. This

enhanced worker efficiency and also improved the utilization rate

of tools and transportation vehicles.

See WEF’s announcement on the latest wave of new members joining

the Global Lighthouse Network, including UMC.

About UMC

UMC (NYSE: UMC, TWSE: 2303) is a leading global semiconductor

foundry company. The company provides high-quality IC fabrication

services, focusing on logic and various specialty technologies to

serve all major sectors of the electronics industry. UMC’s

comprehensive IC processing technologies and manufacturing

solutions include Logic/Mixed-Signal, embedded High-Voltage,

embedded Non-Volatile-Memory, RFSOI, BCD etc. Most of UMC's 12-in

and 8-in fabs with its core R&D are located in Taiwan, with

additional ones throughout Asia. UMC has a total of 12 fabs in

production with combined capacity of more than 400,000 wafers per

month (12-in equivalent), and all of them are certified with IATF

16949 automotive quality standard. UMC is headquartered in Hsinchu,

Taiwan, plus local offices in United States, Europe, China, Japan,

Korea & Singapore, with a worldwide total of 20,000 employees.

For more information, please visit: http://www.umc.com.

Note from UMC Concerning Forward-Looking Statements

Some of the statements in the foregoing announcement are

forward-looking within the meaning of the U.S. Federal Securities

laws, including statements about introduction of new services and

technologies, future outsourcing, competition, wafer capacity,

business relationships and market conditions. Investors are

cautioned that actual events and results could differ materially

from these statements as a result of a variety of factors,

including conditions in the overall semiconductor market and

economy; acceptance and demand for products from UMC; and

technological and development risks. Further information regarding

these and other risks is included in UMC’s filings with the U.S.

Securities and Exchange Commission. UMC does not undertake any

obligation to update any forward-looking statement as a result of

new information, future events or otherwise, except as required

under applicable law.

1 All figures in this paragraph show % change between 2019 and

2023.

View source

version on businesswire.com: https://www.businesswire.com/news/home/20250114984209/en/

Media contact UMC Corporate

Communications Michelle Yun 886-3-578-2258 x16951

michelle_yun@umc.com

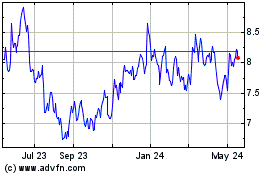

United Microelectronics (NYSE:UMC)

Historical Stock Chart

From Jan 2025 to Feb 2025

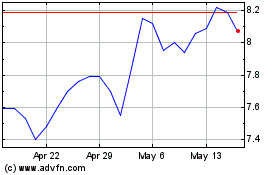

United Microelectronics (NYSE:UMC)

Historical Stock Chart

From Feb 2024 to Feb 2025